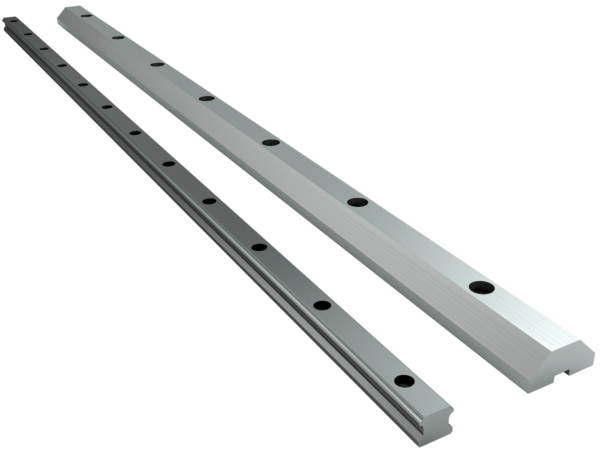

This blog post will shed some light on what to look for when interchanging linear guide profile rails.

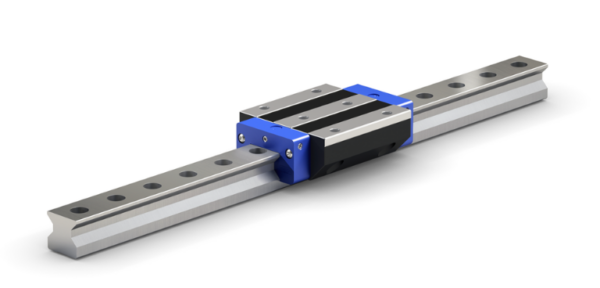

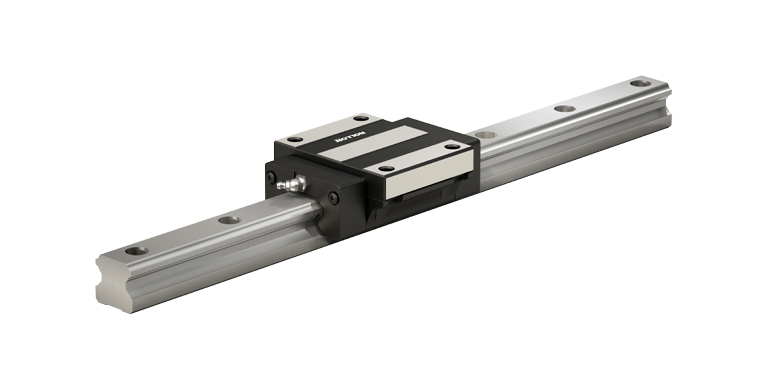

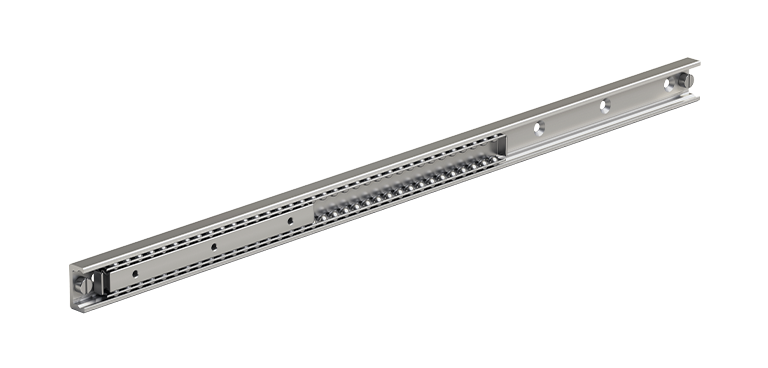

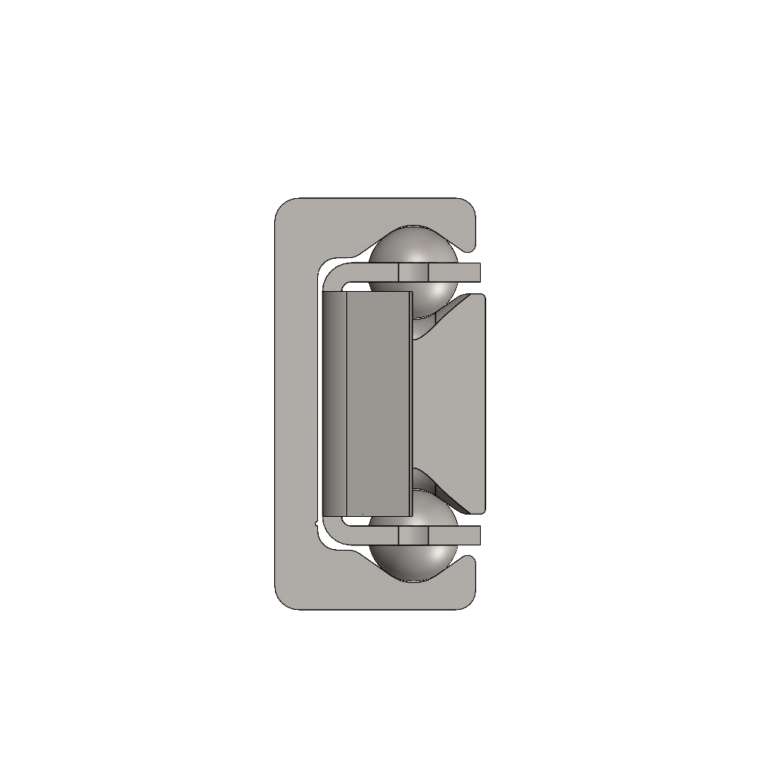

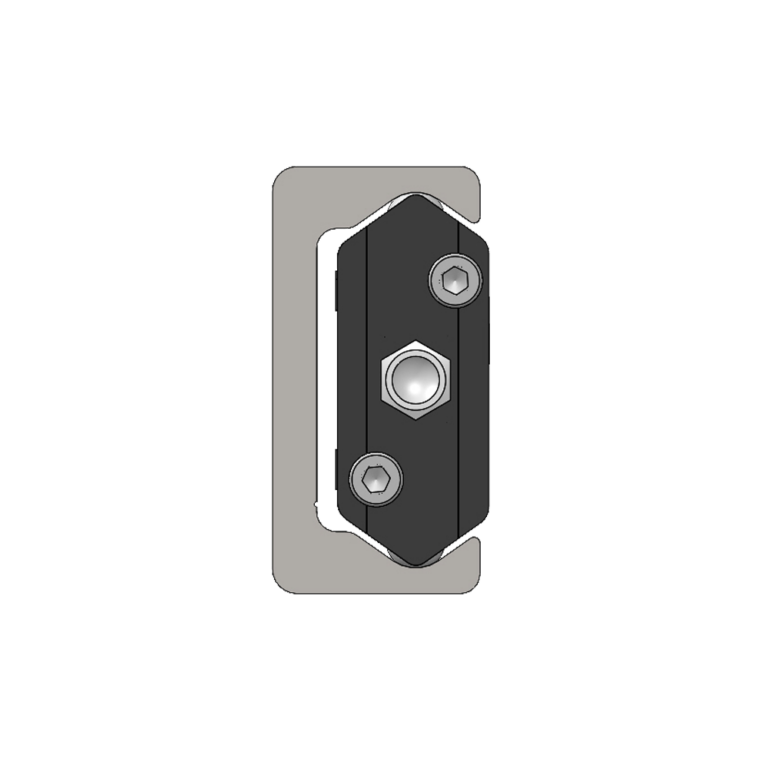

Dimensions and capacities. The importance of dimensions like rail width, dynamic capacity, roll moment and accuracy grade are obvious to anyone familiar with linear guides. However, when replacing an existing profiled rail with a different manufacturer’s linear block and rail, some less obvious dimensions and technical specifications are just as important including:

- The mounting hole pitch spacing of the rail.

- Counterbore rail mounting holes.

- Width of the linear block.

- Length of the linear block.

- Mounting hole pattern of linear block – lateral direction.

- Mounting hole pattern of linear block – axial direction.

- Mounting SHCS (socket head cap screw) size to linear block.

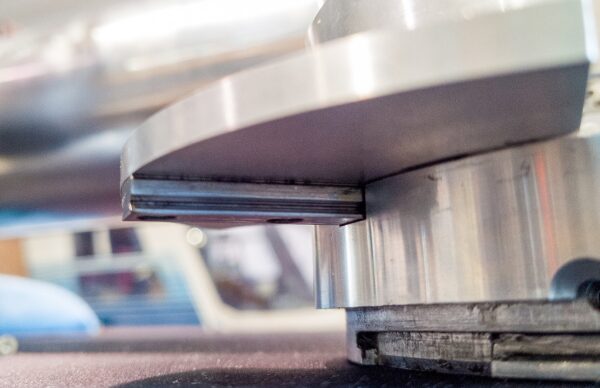

Common issues. Swapping out the wrong sized rail is one of the most common missteps. Engineers will often use the same manufacturer for a rail and linear block. And if something happens to either one, they might think they can switch to a different manufacturer. But in reality, most of these parts aren’t interchangeable.

Design engineers also run into problems with the dimensions in the mounting hole pattern. They design one manufacturer’s linear block, then swap it out. Working with the engineer helps make sure they’re aware of anything that can go wrong.

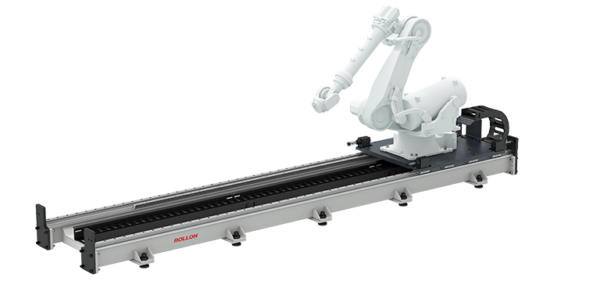

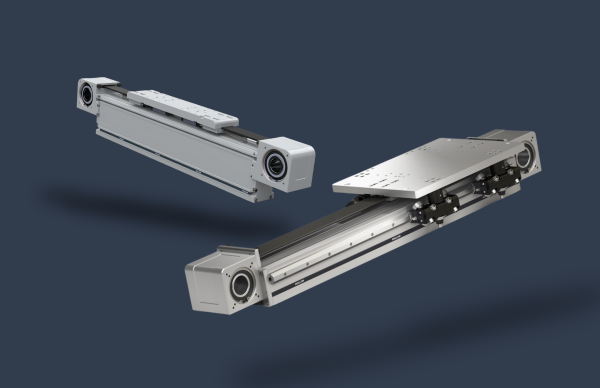

Move Fast With Rollon. Engineering and material purchasers usually look for a new vendor when they encounter a problem due to customer service, pricing or lead-time. With our Move Fast With Rollon program, we’ve found a way to solve these problems with competitive pricing and next day shipping on the most common sizes. We’ve created and published a comprehensive interchange chart, and our TechSupport and engineers can provide a comparison sheet for your reference.

For more information and technical data, download the Linear Line Catalog.