The Purpose of Linear Rail Guides

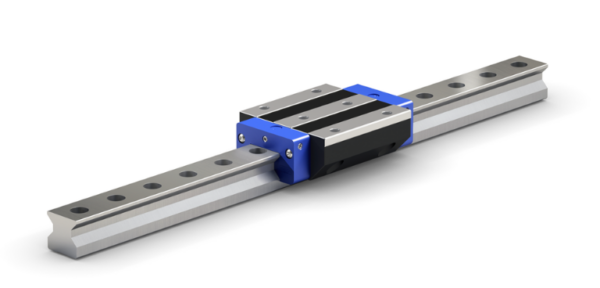

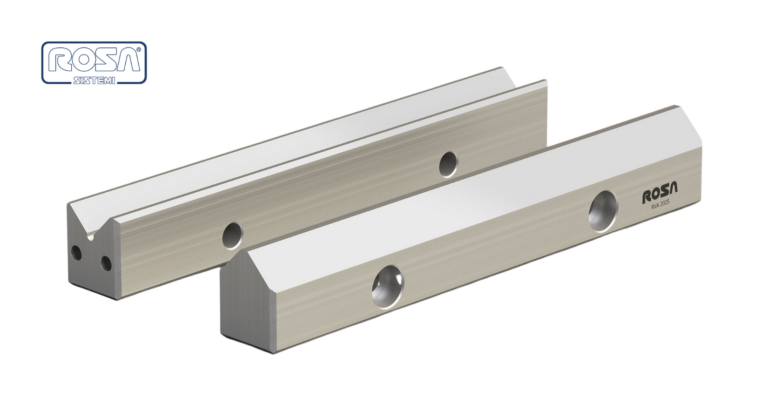

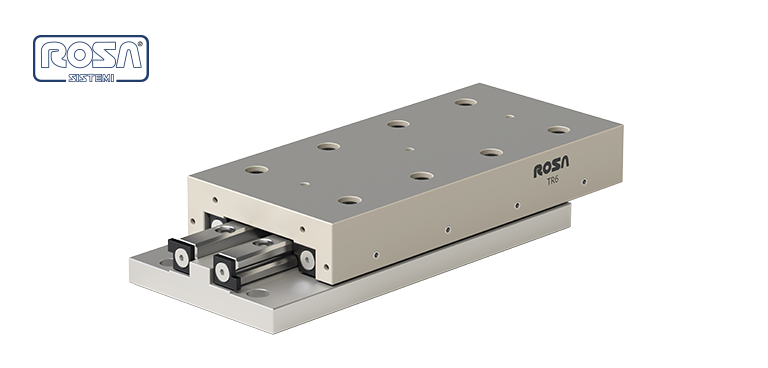

Linear rails are designed to increase efficiency in your workflow, whatever that might be. If you have a manufacturing or packing process, then you understand the importance of precision. Every moment matters from start to finish.

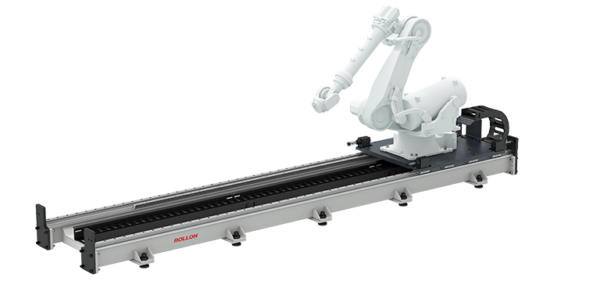

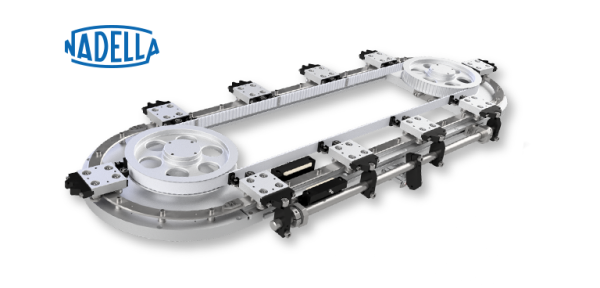

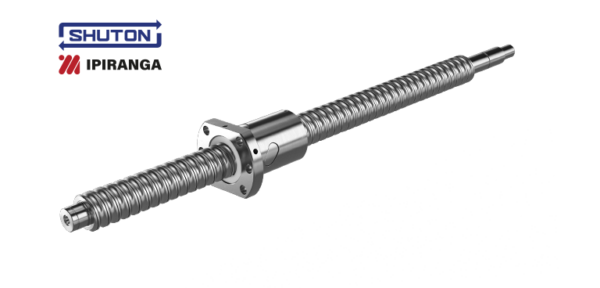

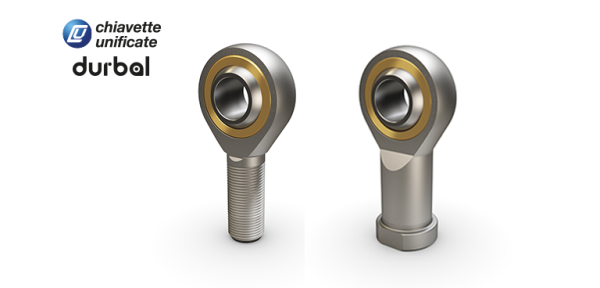

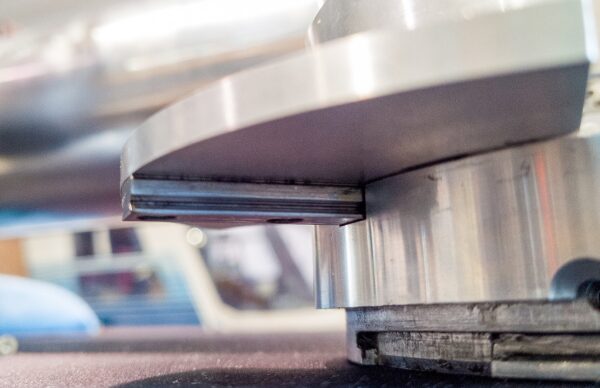

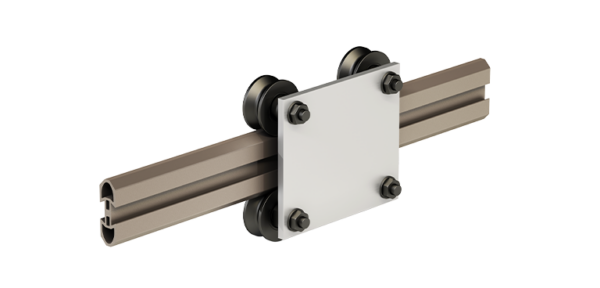

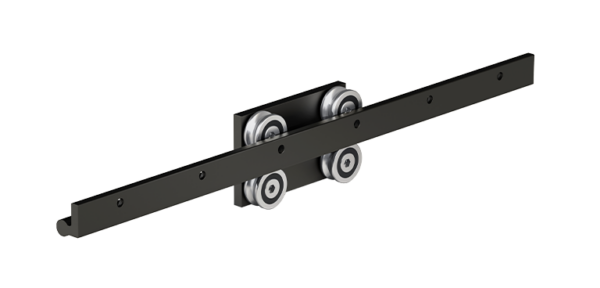

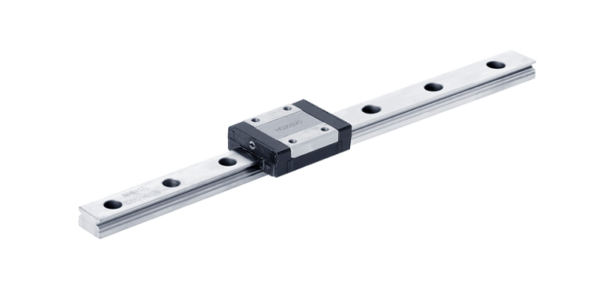

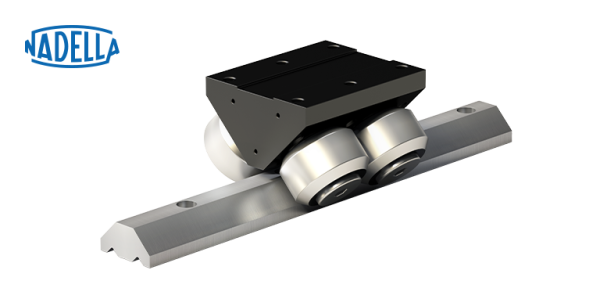

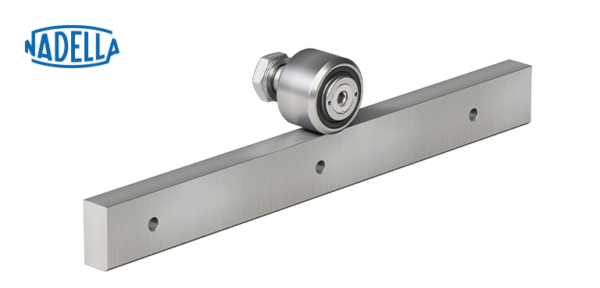

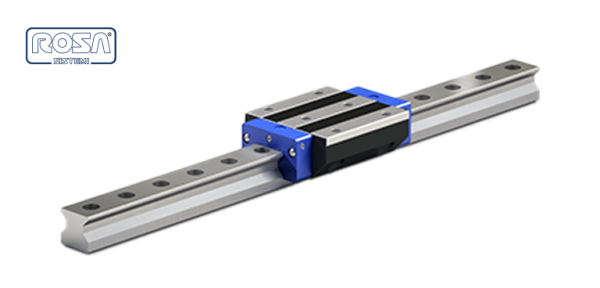

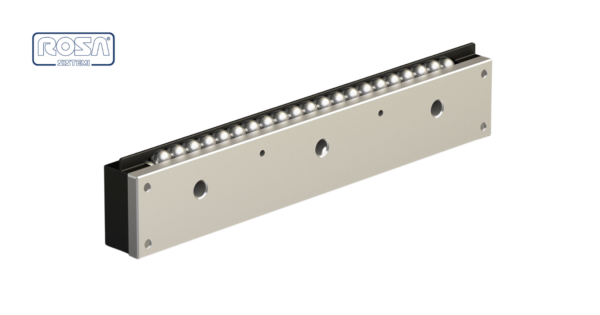

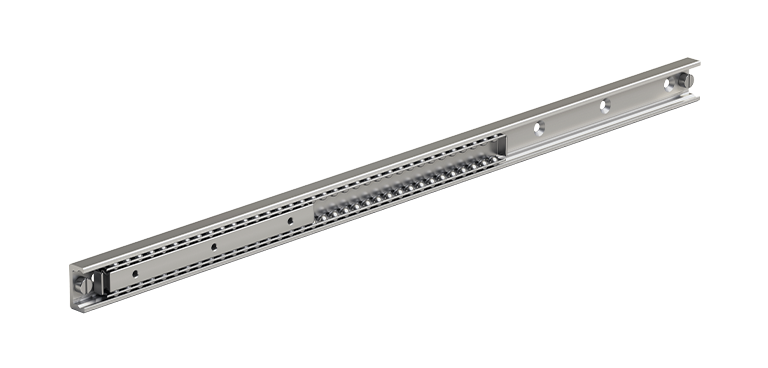

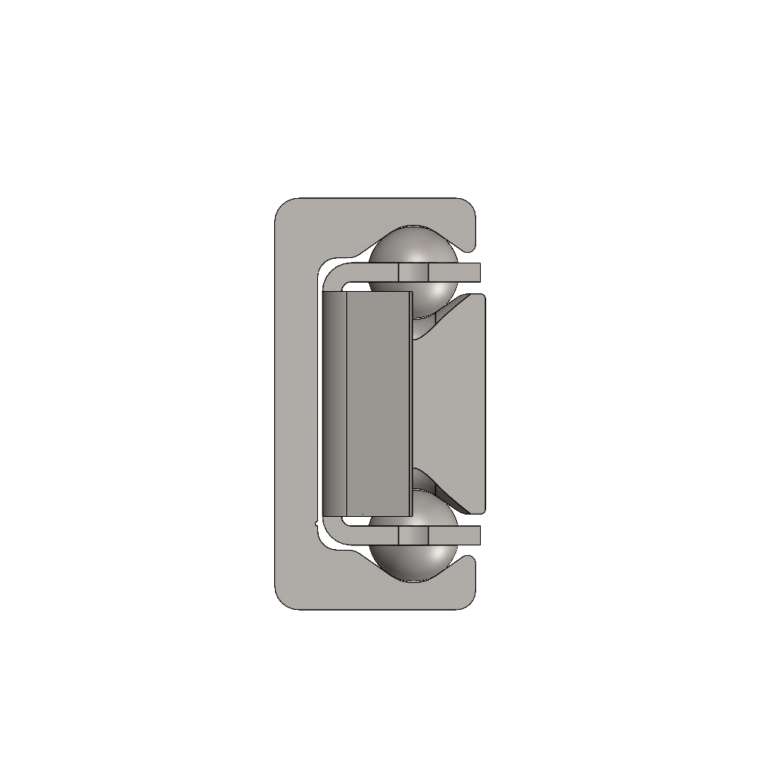

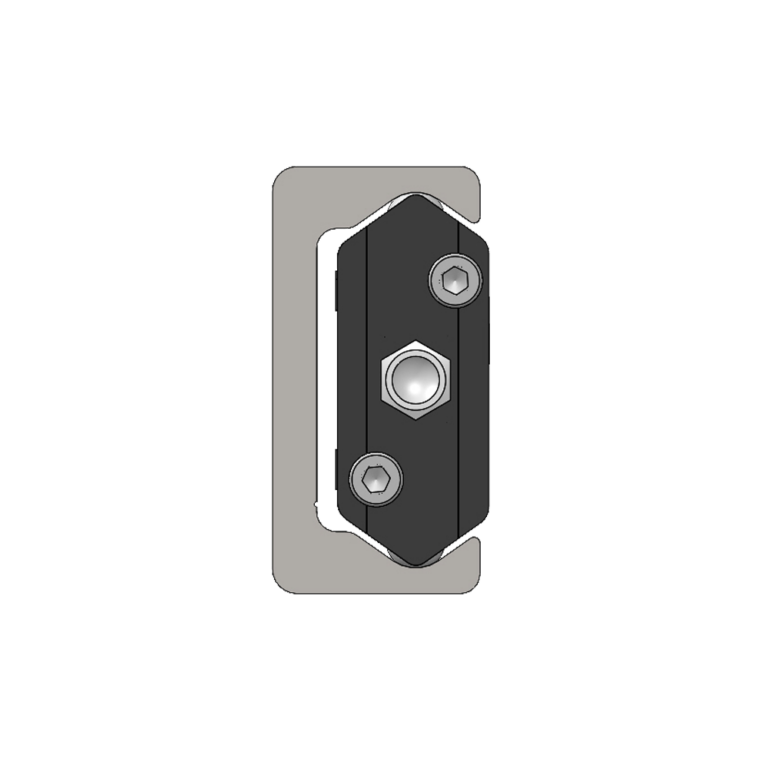

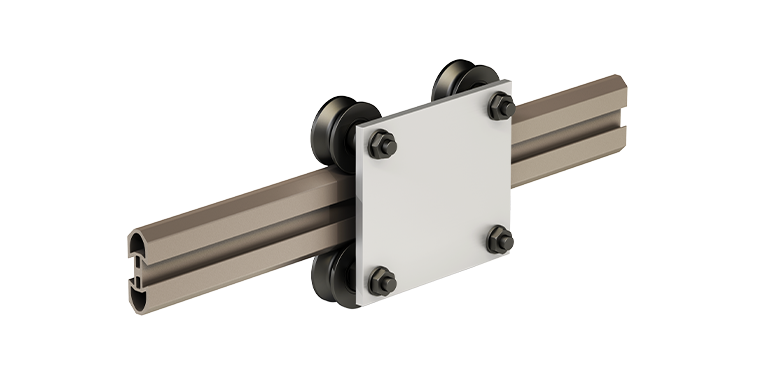

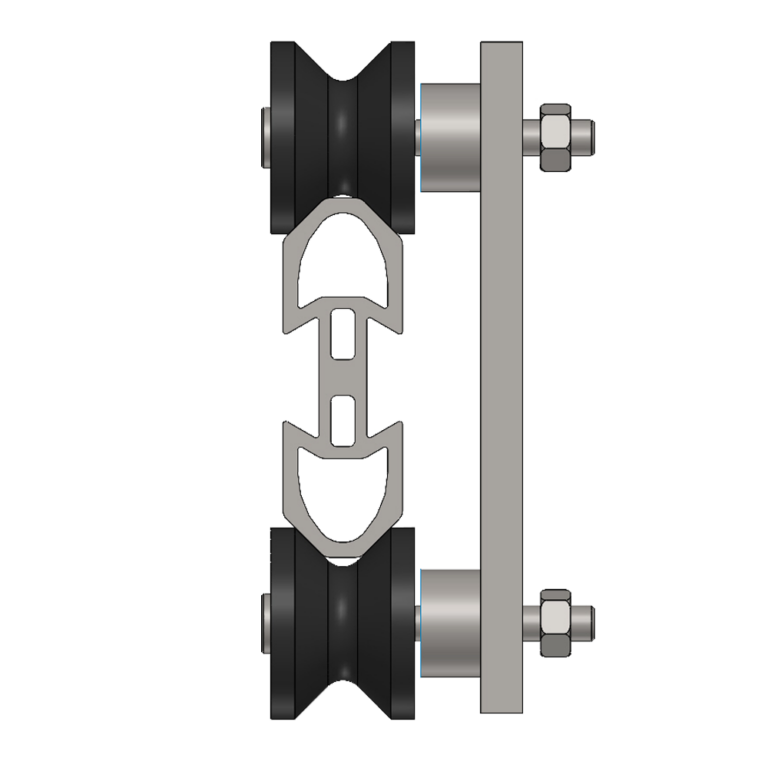

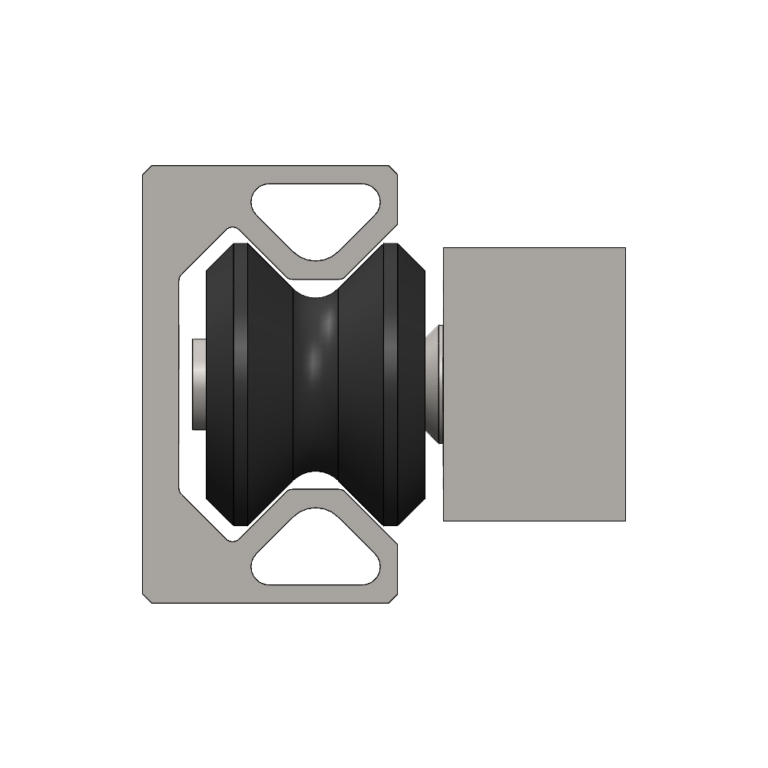

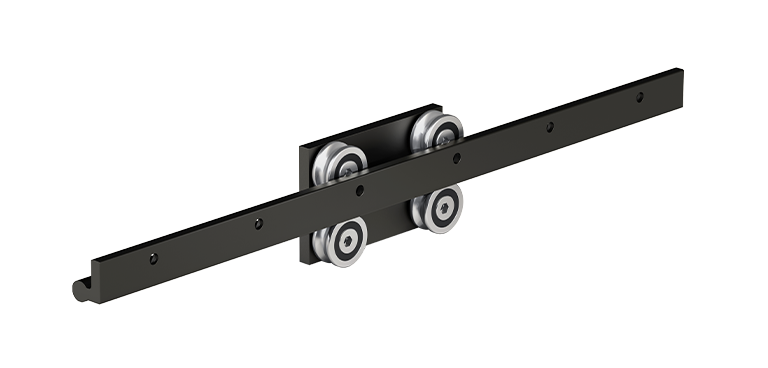

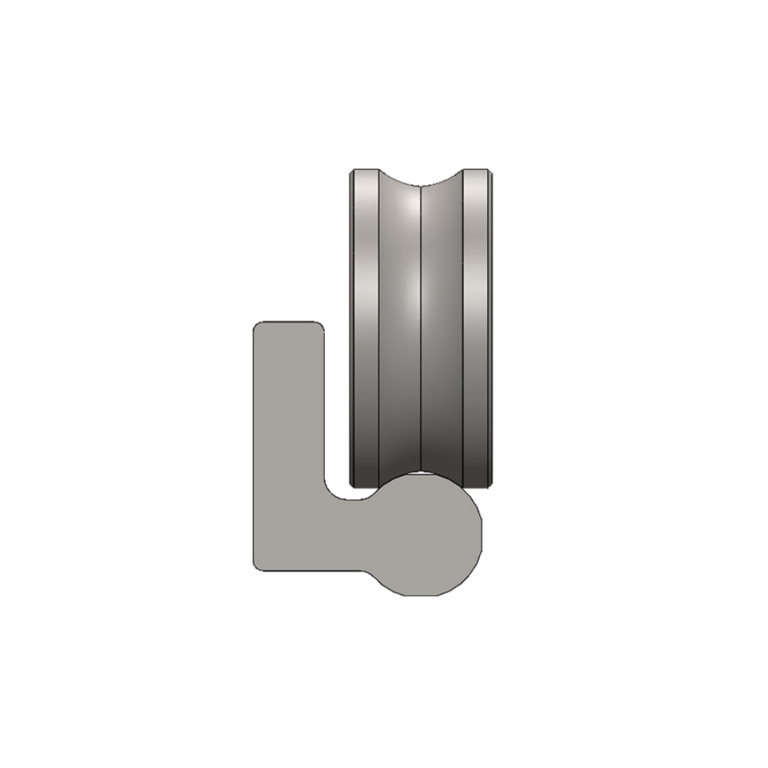

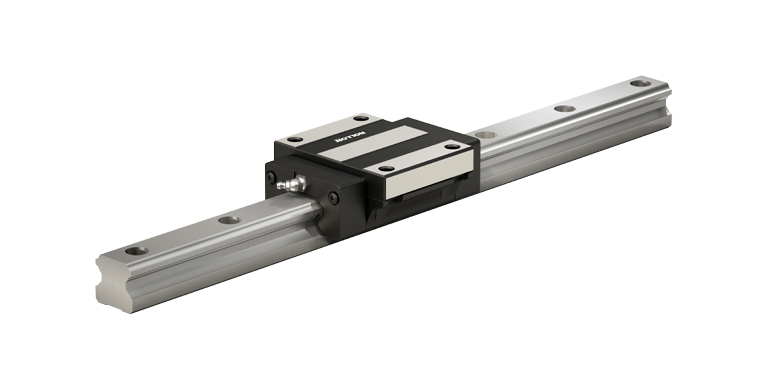

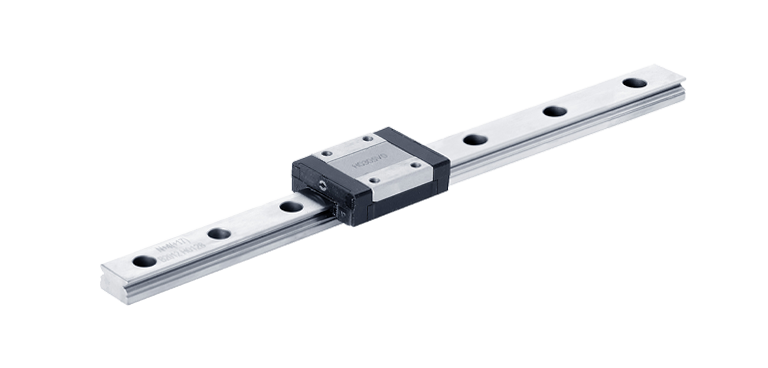

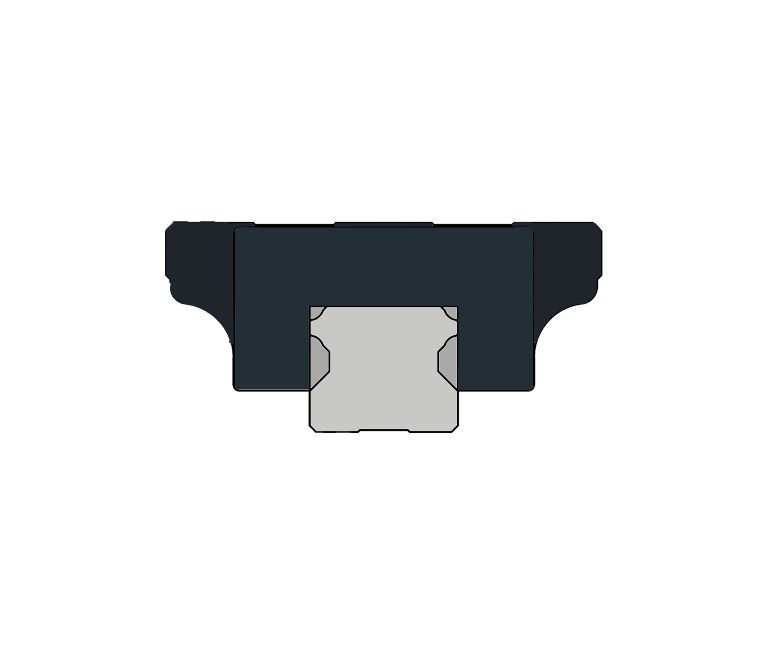

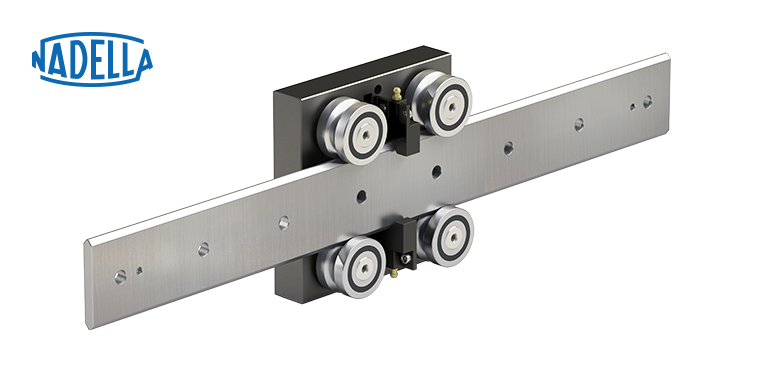

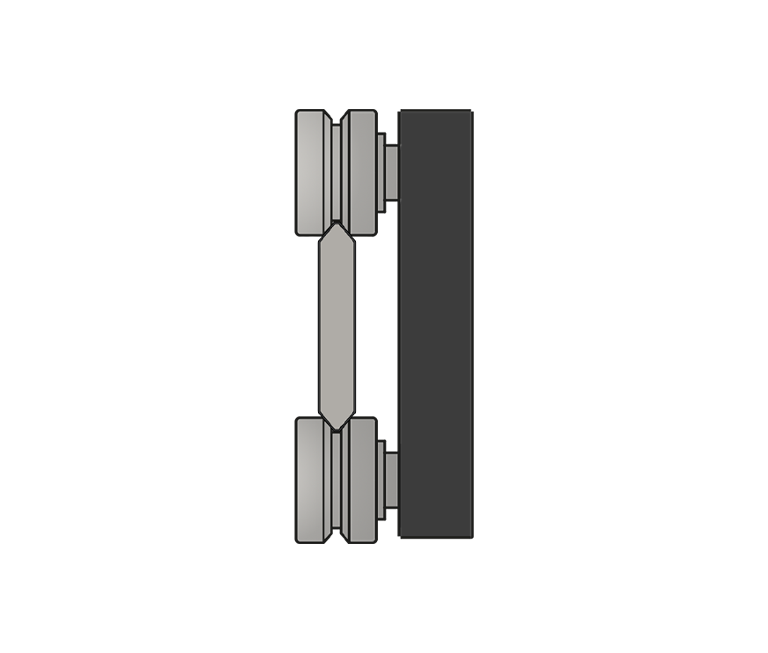

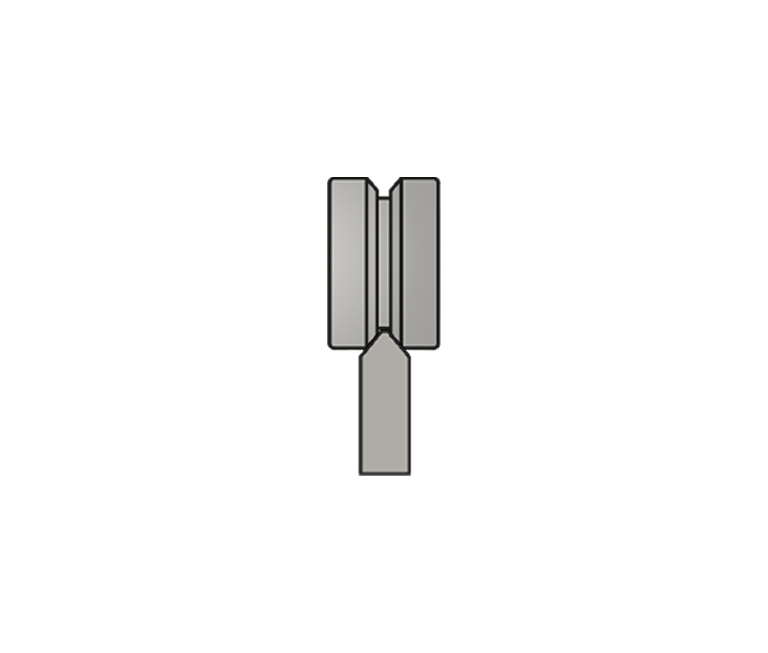

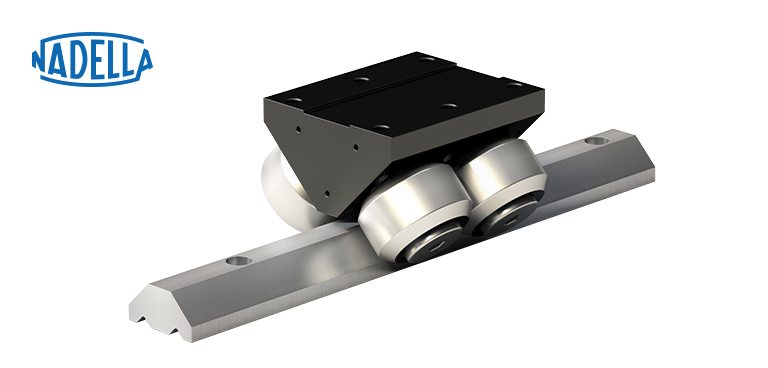

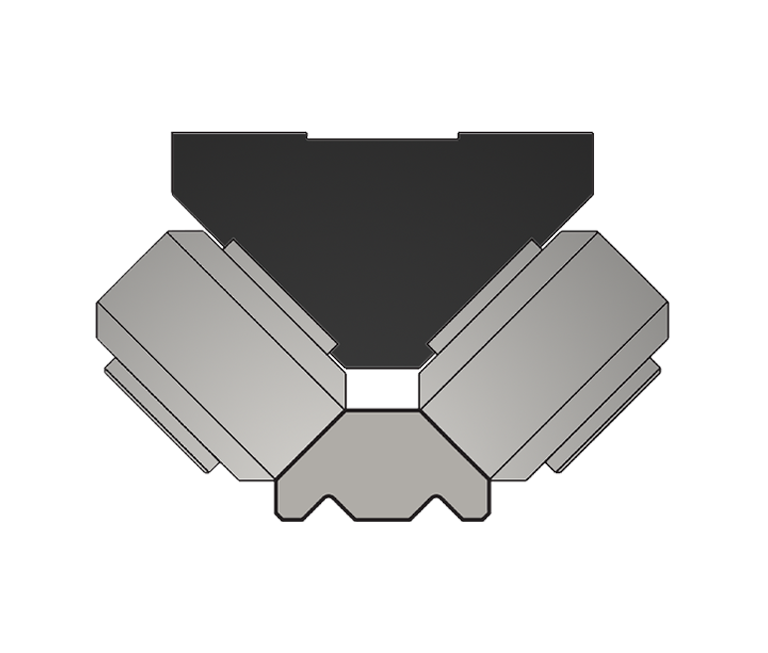

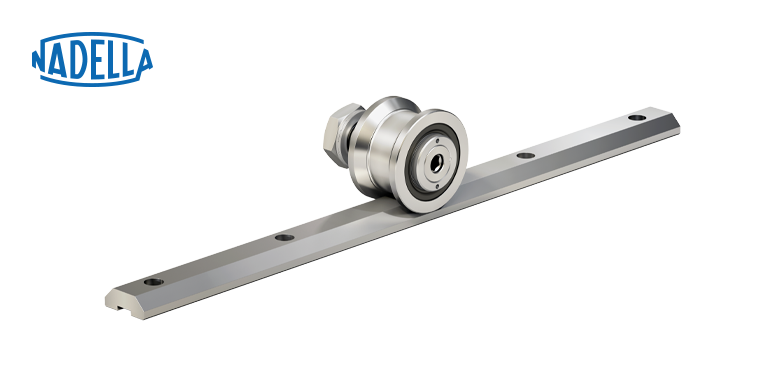

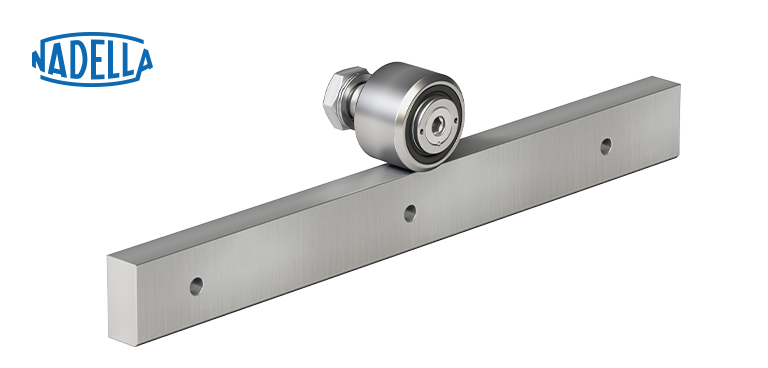

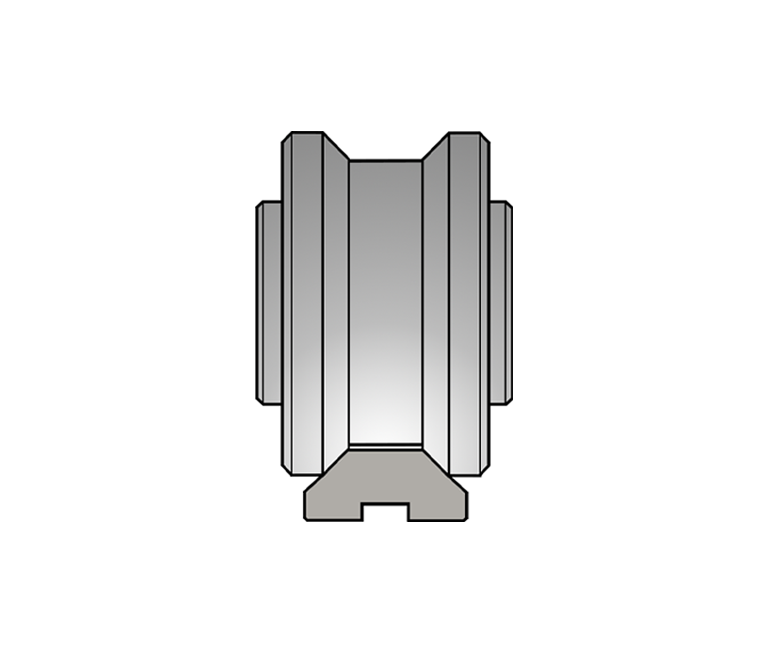

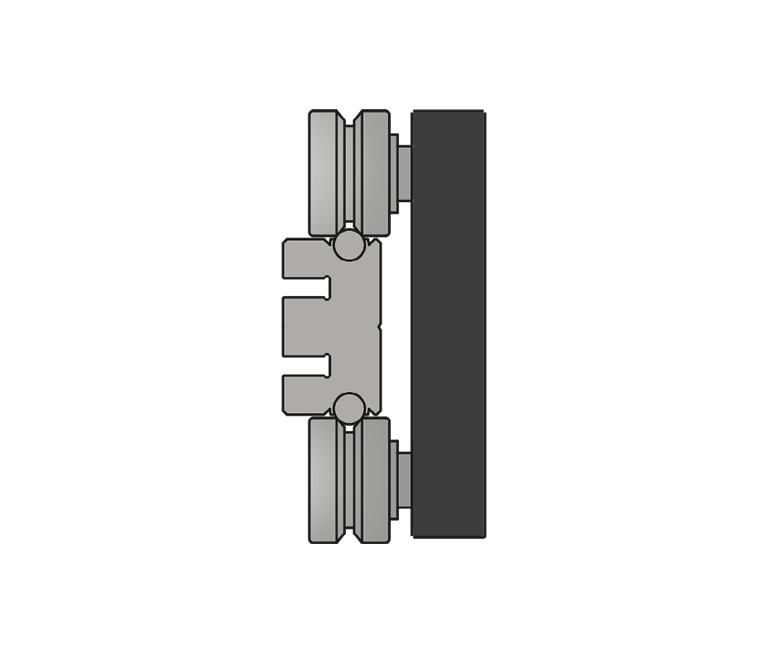

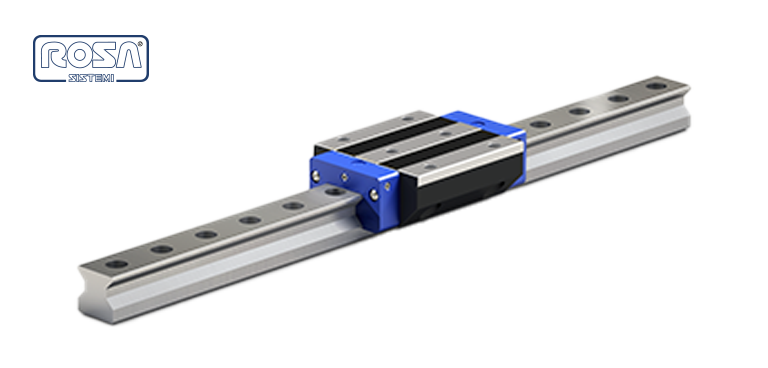

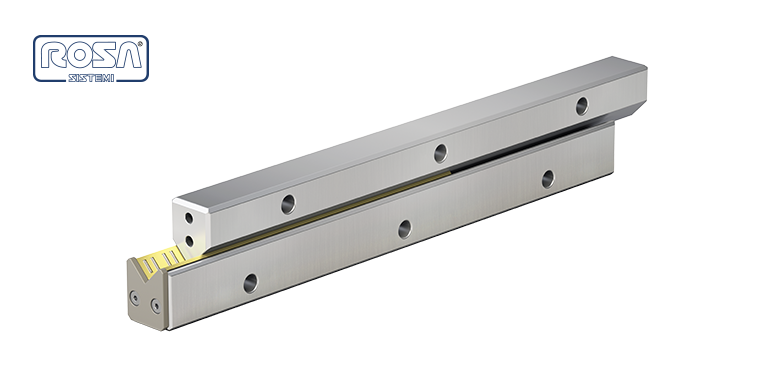

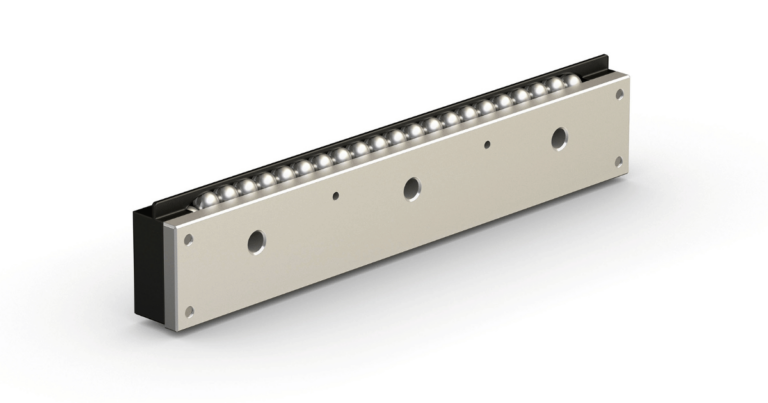

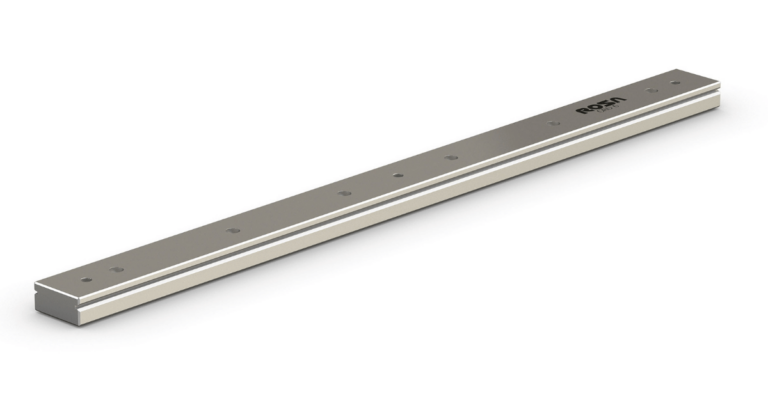

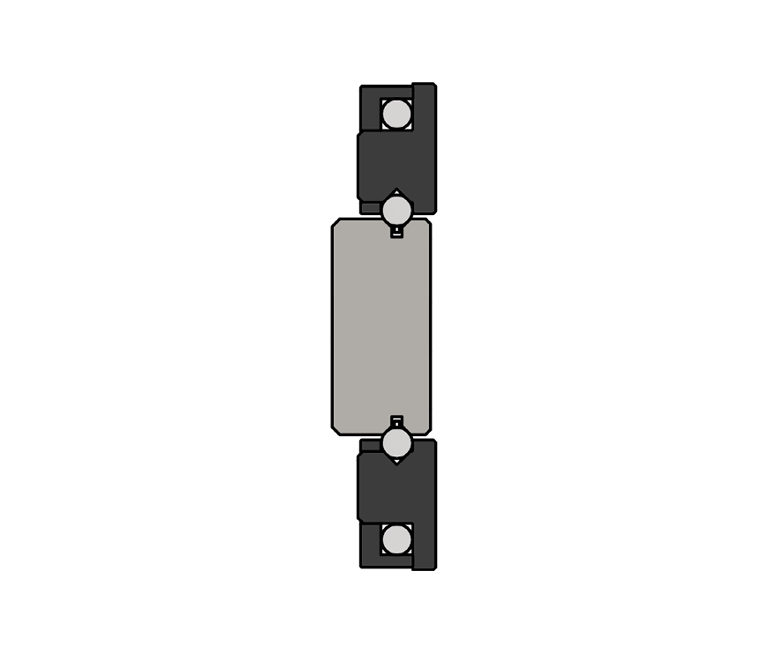

Linear rail guides support the movement of a product or package in a linear motion. They do this accurately, swiftly, and without friction. Additionally, the precision of linear guide rail systems increases safety as well. With all of these benefits, it’s no wonder why manufacturing plans and warehouses make wide use of linear rails.

And this linear motion isn’t limited to horizontal movement. Linear guide rails can move an item vertically as well, doubling the efforts of any production line. But the differences don’t stop there.

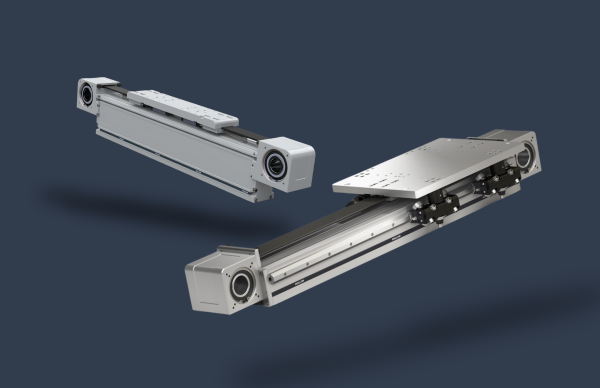

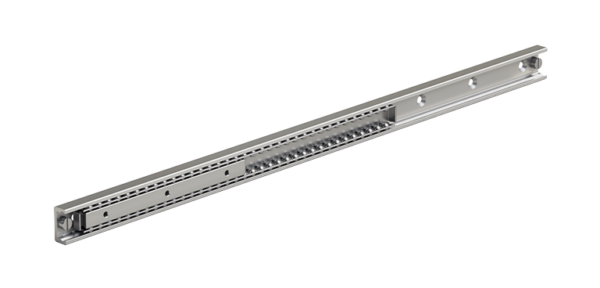

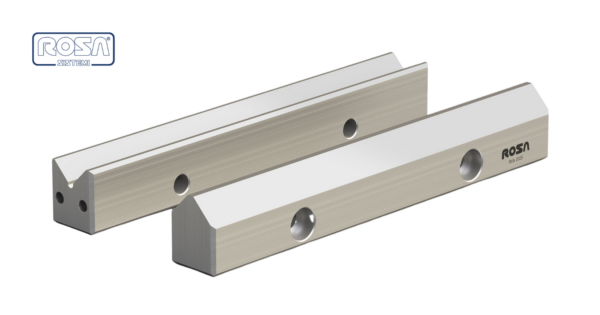

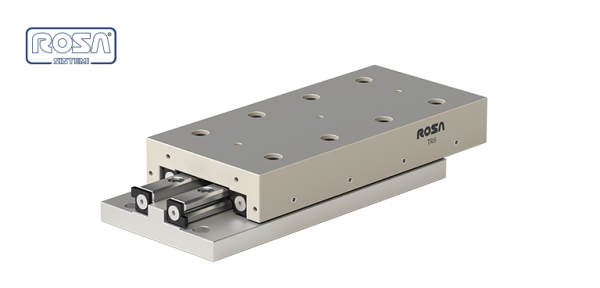

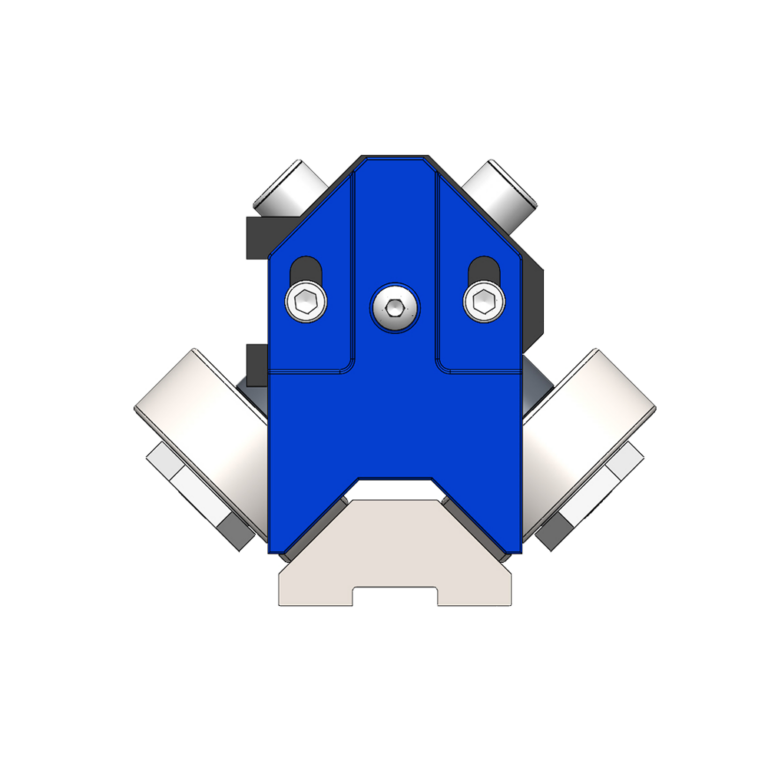

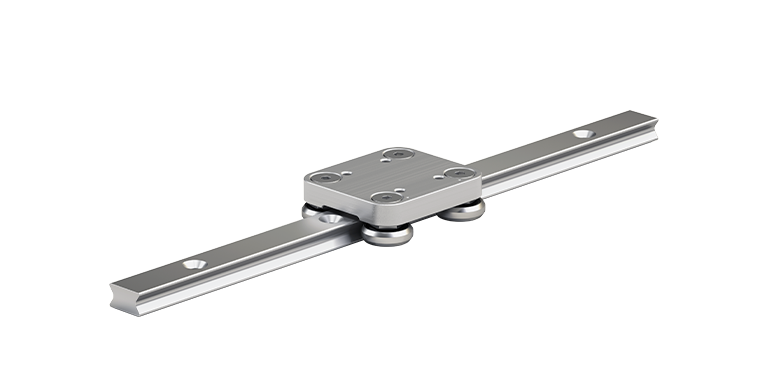

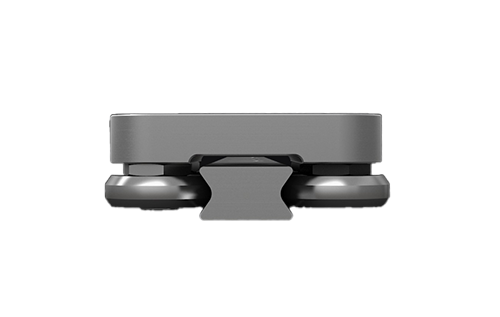

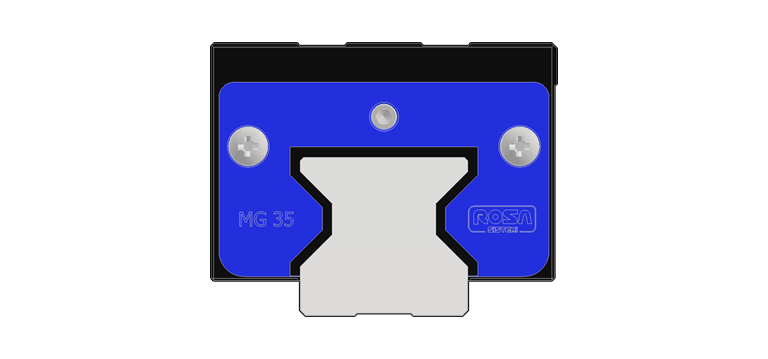

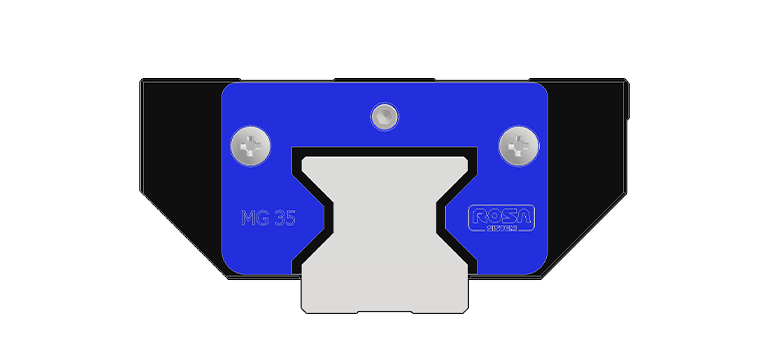

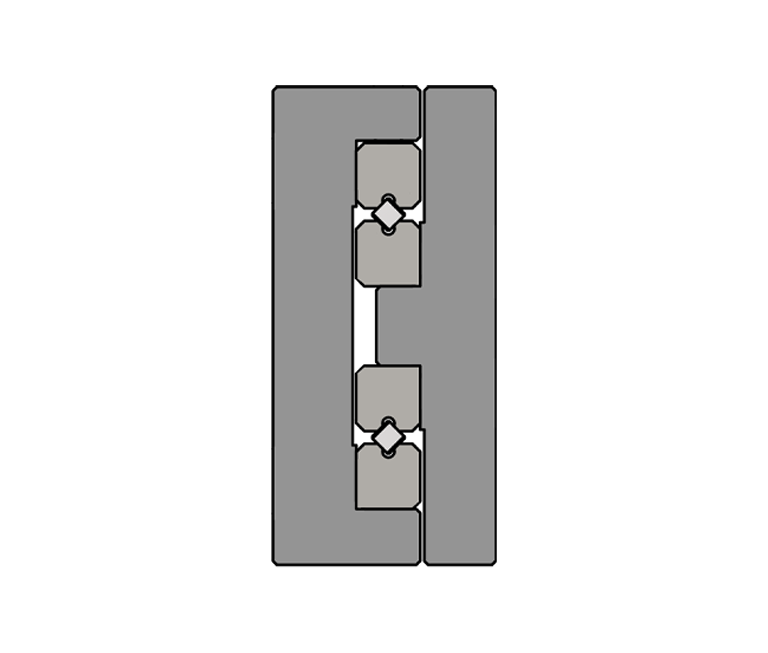

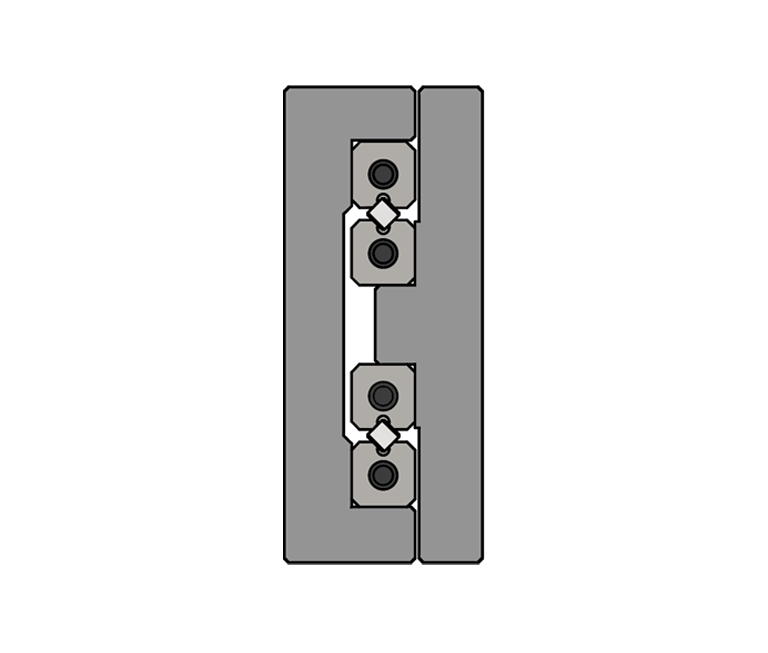

As mentioned, linear rail systems come in all shapes and sizes. They are designed to handle any load, as long as you consider the right equipment. Because of this, there are all sorts of options at your disposal. Essentially, choosing the right rail system is considering what would work best with your operation.

The right linear guide system for you will be the one that best supports your needs. Below are the types of Rollon Linear Rails. As you will see, they are not one size fits all. This enables you to really dial in and find what makes the most sense for you.

- All

- Industrial Machines

- Railway

- Packaging and Logistics

- Aerospace

- Building and Furniture

- Special Vehicles

- Medical

- Integrators

- Robotics

- Textile

- Vertical Farming