Robot-transfer or transport units (RTUs) are long railway-type linear axes that extend the reach of the robots they transport through automated workcells often to help companies maximize use of their investment in robotics. Called seventh-axis systems when used to transfer common six-axis robot arms (having six degrees of freedom) these RTUs have seen an uptick in adoption over the last two decades complementing the dramatic rise in industrial robots and collaborative robots since 2010 especially.

RTUs most commonly install like a railway — flat on the floor of the automated facility to move attached robots through various stations for the execution of cutting, fastening, coating, other assembly, welding, material handling, and product-finishing processes. However, some settings benefit from wall and ceiling-mount RTU linear tracks integrated into rigid gantry frames straddling an automated scene below and suspending the robot from the linear-track carriage.

To be clear: In this context, the phrase wall mounted indicates RTU arrangements where the rails are wall mounted horizontally that elevate the robot on a dedicated steel frame to provide an X-Y-Z wall of reach. Likewise, the phrase ceiling mounted simply indicates RTU arrangements that suspend the robot, inverted on a dedicated steel gantry to provide an X-Y-Z zone of reach from above. Any RTUs that for whatever reason must directly mount to existing building wall and ceiling structures will necessitate customized solutions. In such instances, contact Rollon to discuss the project.

Wall-mounted RTU arrangements in particular are more suitable than traditional floor-based installations in three instances.

- Where space is limited: Wall-mounted RTUs can nimbly shuttle robots through otherwise cramped factory settings. To illustrate: For RTUs associated with the robotic tending of multiple workstations, wall mounting can keep floorspace between those stations clear for human plant personnel. Elsewhere, a wall-mount RTU can let its attached robot load and unload items on and off a conveyor or execute palletizing tasks on product waiting for shipment while keeping loading bays clear for forklifts and highway-transport vehicles.

To achieve the reach of wall-mount RTU-shuttled robot, a stationary robot of equivalent design would need to be enormous. In contrast, RTU-based installations can transfer heavy loads long distances.

An added benefit is that in some cases, wall mounting allows the robot controls, cable harnesses, and power supplies to be located up and out of the way of plant personnel.

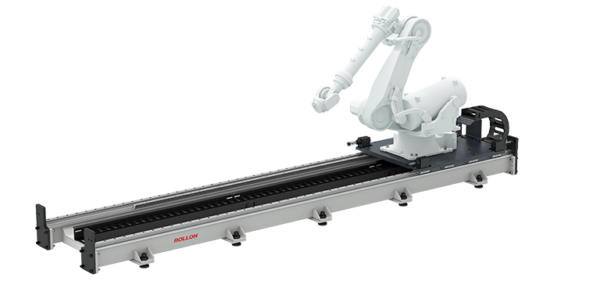

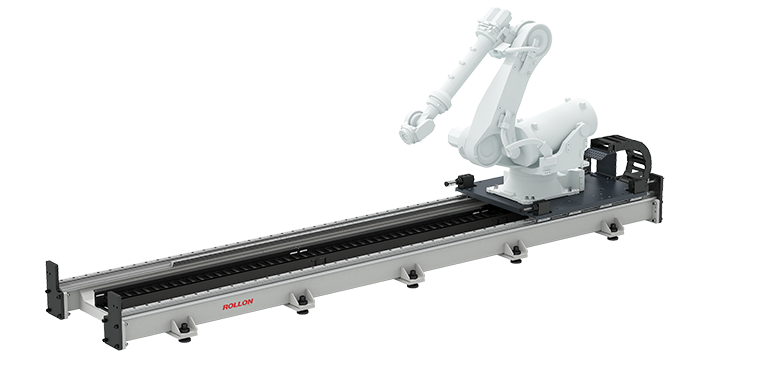

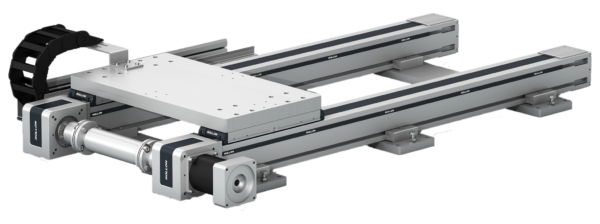

Shown here is a Rollon wall-mount RTU arrangement bearing an industrial robot.

- Where a given operation is best executed from unusual angles: Wall-mounted RTUs can help robots tend machinery that is best reached from above or a given range of angles. For just this reason, wall-mount RTUs are particularly common for welding and painting bulky appliance and automotive bodies. Such arrangements are also employed on assembly lines needing the transfer of large workpieces between workcells.

Robotics moved by wall-mount RTUs rapidly and precisely move through elaborate paths as well — picking and sorting items from above to leverage the unobstructed views of complementary machine-vision systems less challenged by ambient conditions.

- Where a setting needs to be kept clean or clear: In some cases, wall-mount RTUs bear robots that can tightly retract out of an assembly line’s flow of goods. In human-robot collaborative environments, wall-mounted RTU robotics can execute heavy-duty or precise tasks while steering clear of personnel. Or in cleanroom settings, wall-mount RTUs can move robots that can temporarily dip in and out of controlled rooms or areas to minimize particle contamination risk. Wall-mount RTU structures are also easier to build around existing production layouts than traditional RTUs — keeping clear of previously installed equipment that may be extremely difficult and costly to relocate.

Wall-mount RTUs can help robotic arms execute material handling and automation tasks in production facilities and warehouses having limited floor space.

Case in point: One wall-mount RTU example

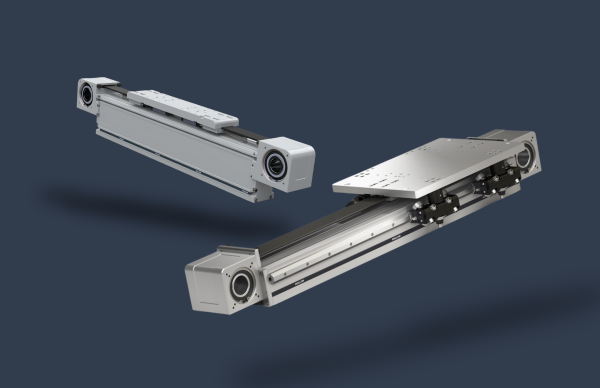

Consider the steel-body Rollon RTUw — a rack-and-pinion driven wall-mounted robotic transfer unit designed to precisely move robots from Kawasaki, ABB, Fanuc, Yaskawa, Kuka, and other suppliers. Leveraging Rollon’s vast technical expertise in helping machine builders engineer cartesian systems, this RTUw includes a both a rigid linear body (serving as the main robot track of travel) and vertical legs made of steel. In fact, the RTUw comes in variations to transfer robots and their payloads from 1 to 15,000 kg. For example, the RTUw-800 carries static payloads of 10,000 to 15,000 kg and dynamic payloads of 3,000 to 5,000 kg.

The designs borrow from well-proven linear-motion automation to extend reach far better (and at far lower cost) than any changes to the robotic design itself would allow. That’s especially true as robots have inherently inflexible work volumes. In contrast, RTUs such as the RTUw designed around electric-motor-driven rack and pinion sets have theoretically endless strokes able to move robotic arms between adjacent machining zones, assembly areas, and other work stations.

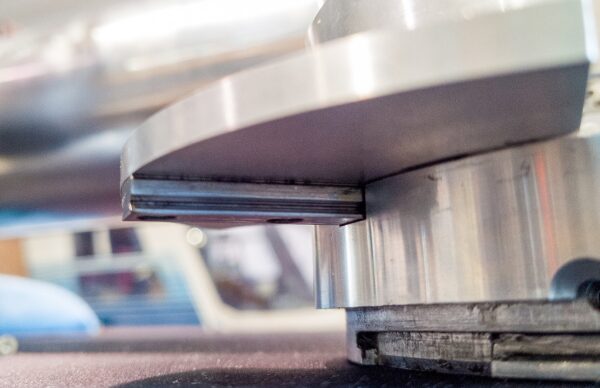

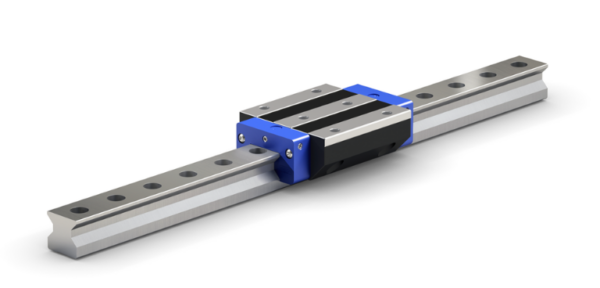

Rollon RTUw systems have servomotor-powered rack-and-pinion linear drives with machined ends for easy assembly, expansion, or retooling. Completing the assembly are precision linear guides, carriage wipers, and single-point lubrication for strokes to 3 m/sec and 3m/sec² at ±0.020-mm repeatability. Optional Rollon RTUw features include automatic PLC-commanded lubrication; robot risers and application-specific equipment platforms (including cleanroom, explosion-proof, and washdown variations); sensor brackets and cam rails; and assembly as well as metrology support.

Just a few caveats to wall mounting robotics with RTUs: The robot itself must be adaptable to or specifically designed for wall-mount orientations. To maintain stability and accuracy values, axes’ homing, zeroing, joint-limit, and gravity-related parameters must be set to account for the robot’s mounting orientation. In addition, cables must be secured in some manner to avoid wear and programming must designate the wall-mount orientation for proper path following and the satisfaction of safety requirements.

Next steps in designing a wall-mount robot installation

For more information on how to integrate RTUs into your automated installation, download this Rollon white paper. Or enter your own application’s parameters and explore the extensive capabilities of Rollon’s RTUs at the myRollon Multi-Axis Systems configurator. Also be sure to visit my.rollon.com/corp/products/actuator-system-line/rtuw.