In the world of load bearings, you have a lot of options. But if you are new to handling this type of machinery, don’t be overwhelmed. Getting more familiar with the difference between axial vs radial loads can help you feel confident in your choice toward improved performance.

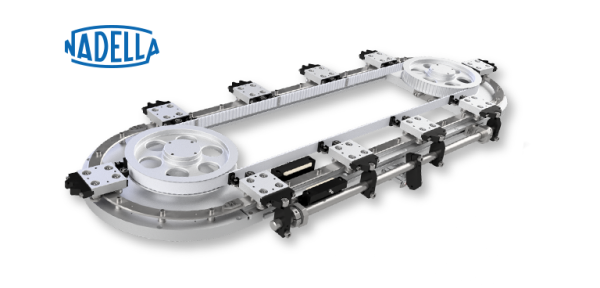

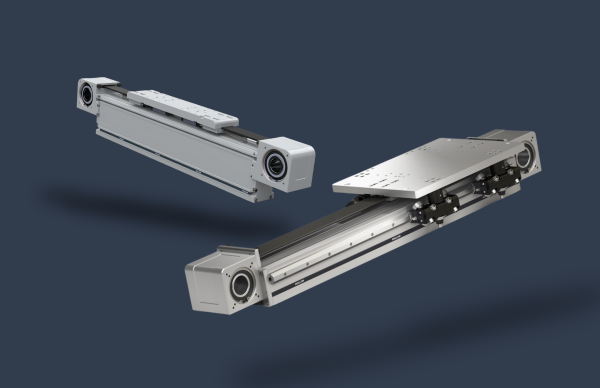

Linear motion products are not one-size-fits-all. Since no single industry need for these products is the same, the variety is beneficial to the user. From size to shape to speed to functionality, having options can lead to greater performance successes.

But with such a variety, how do you know which linear motion product is right for you? Research and positive reviews about certain products can help sway your decision, but your operation is unique. To choose your ideal linear motion product, you need to learn a bit more about their capabilities.

This doesn’t mean you have to become an expert. It simply means gaining a basic understanding of certain mechanical aspects. In this instance, analyzing the differences between an axial load vs a radial load. By demonstrating the simple differences, you can more accurately choose a product that meets your needs.

However, it is important to make a quick note about ratings. If you are comparing radial loads vs axial loads, you will find axial ratings to be lower. Don’t let this sway your decision until you have a better understanding of both types. Only once you understand the characteristics of both types of loads can you compare the ratings with confidence.

Axial and Radial Loads: The Basics

Axial loads

As the name suggests, an axial load is literally a load that goes into an axle.

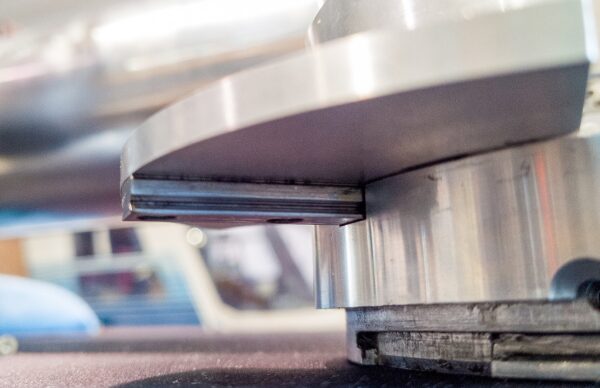

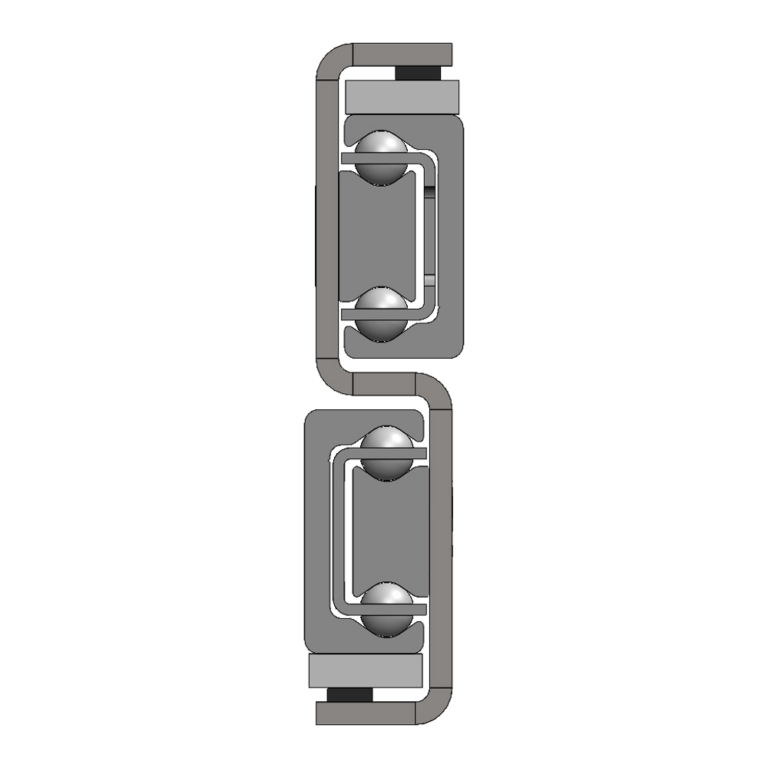

In fact, an axle on a car demonstrates axial load forces well. When a car drives around a corner, the wheels must be able to handle the sideways load. For a roller-type bearing like our Compact Rail, the rollers spin around a center axle. That means the load is going into the axial, or mounting, surface.

Radial loads

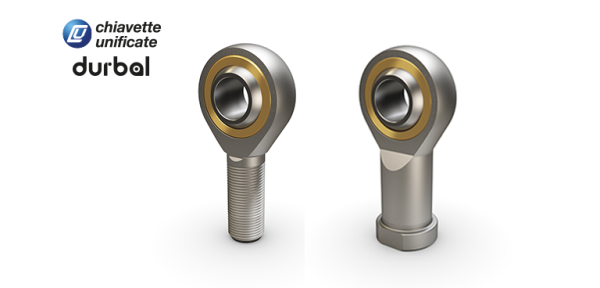

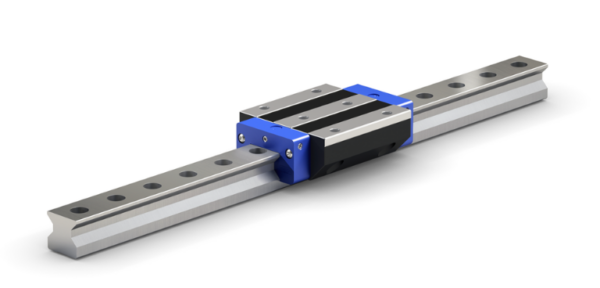

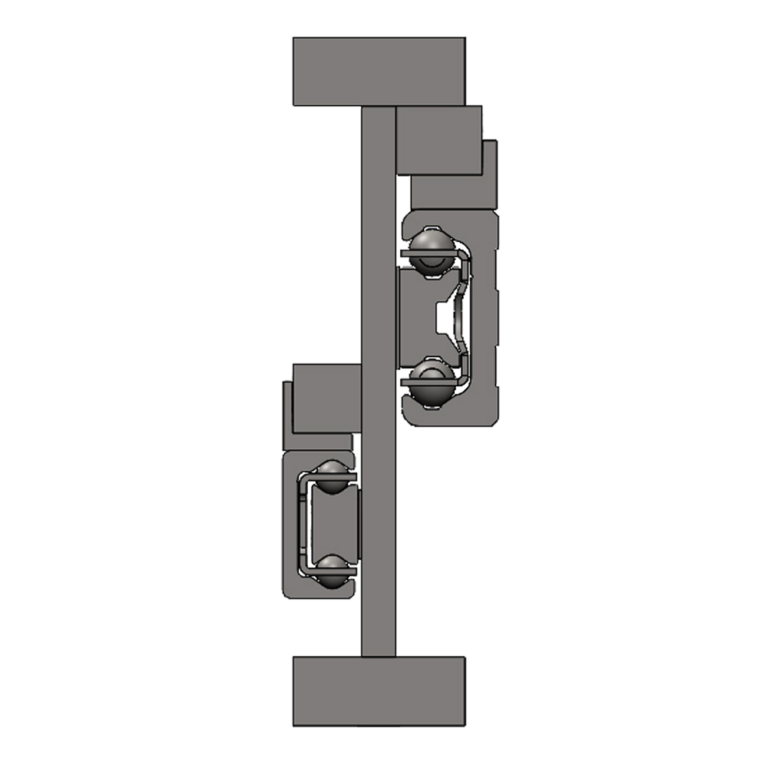

To understand radial loads, consider a circle and its radius. The radial force in a roller moves directly from the outside of the roller toward the center. As this happens, the radial load moves away from the axis.

Radial loading is always higher than axial loading because the internal bearings have the full support of the raceway. The axial load, on the other hand, only has a partial engagement.

Consider the Trajectory

A simple way to compare radial vs axial loads is to consider the direction of force. Specifically, if force is applied perpendicularly to a shaft, the load is radial. If the force is applied in the same direction as a shaft, the load is axial.

So if we can return to our car example, we can easily differentiate axial vs radial. As mentioned, the force used to turn the car around the corner is axial. While the force of the vehicle weight pushing down is radial.

In this example, it’s easy to see how bearings can have forces applied to them from all directions. THerefore it is crucial to get the right type of bearing. And as mentioned, that’s why understanding the trajectories of force is necessary.

Non-Roller Style Bearings

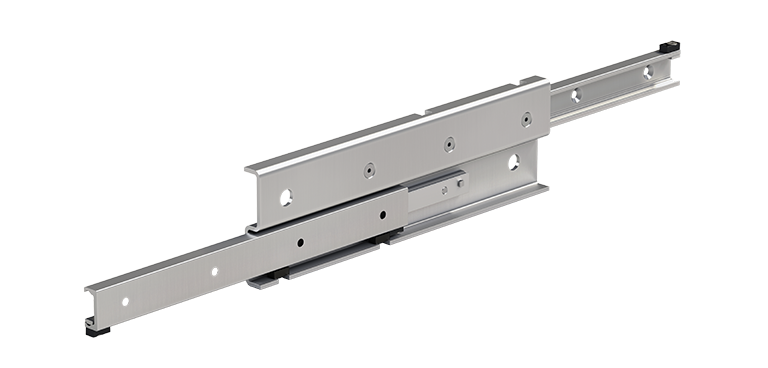

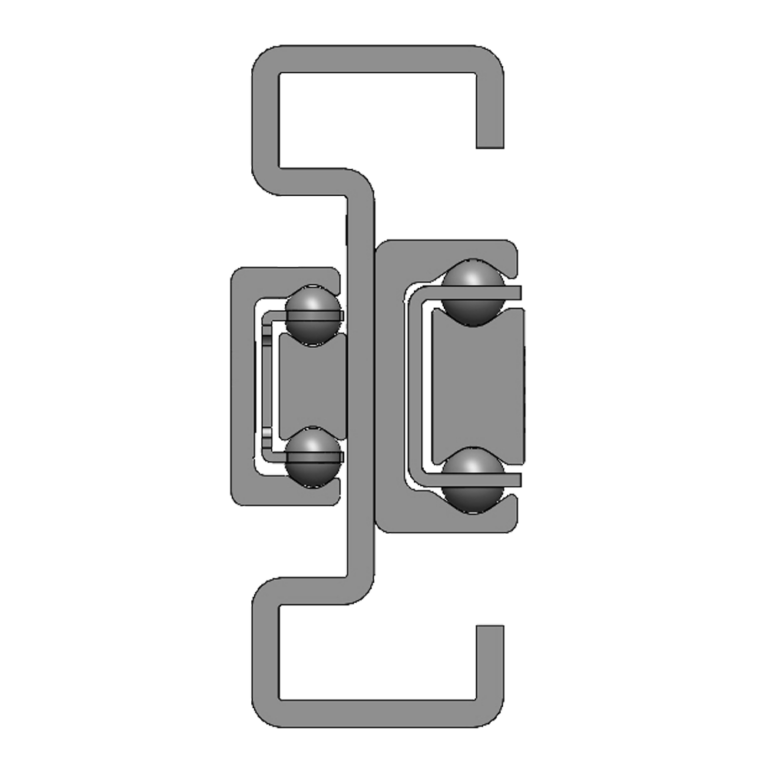

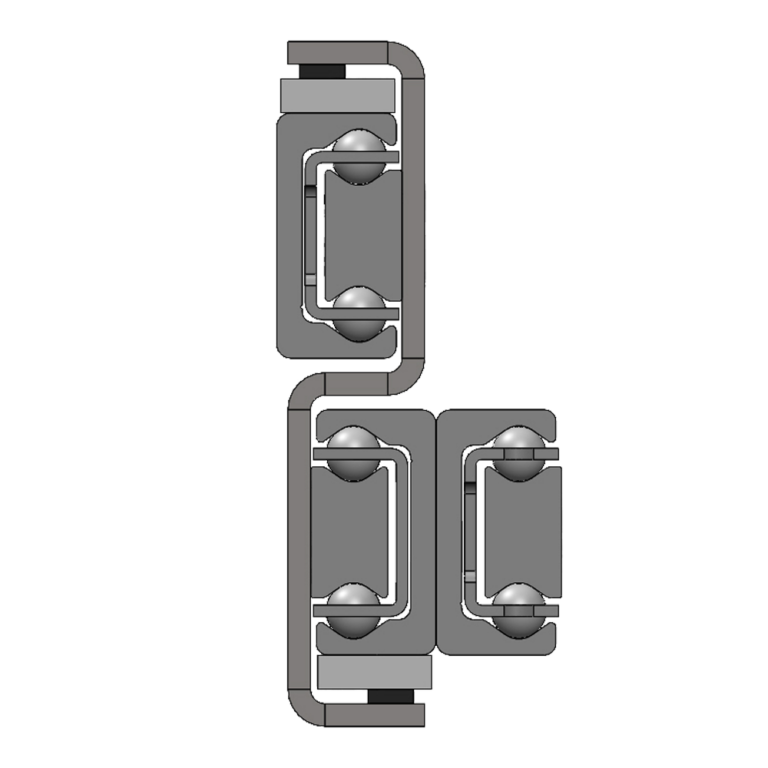

Axial and linear loads are pretty easy to visualize with roller style bearings. This is so because it’s easy to see the roller’s rotation. However, telescopic rails or bearings with recirculating balls are less straightforward.

Telescopic Rails have individual balls which roll along the surface of the rail. Even though the ball is round, the same rules apply. Each ball will have a theoretical axle or axis that the ball circles around. The axial load will be straight into the axis, and the radius comes from the axis.

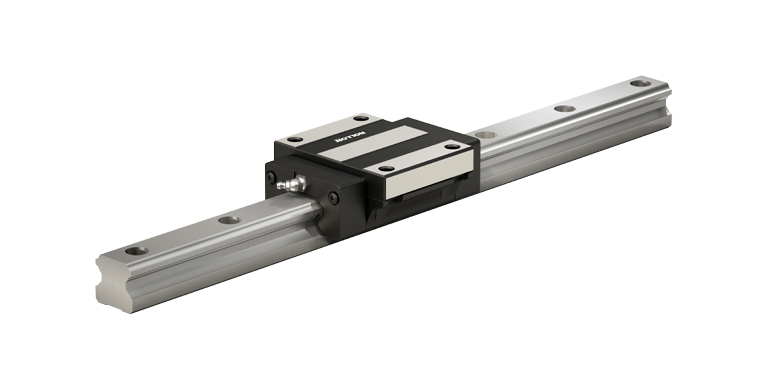

Note that with the telescopic rail, the load ratings are typically given for a pair of rails. Telescopic rails are not made for handling twist, so a pair is required.

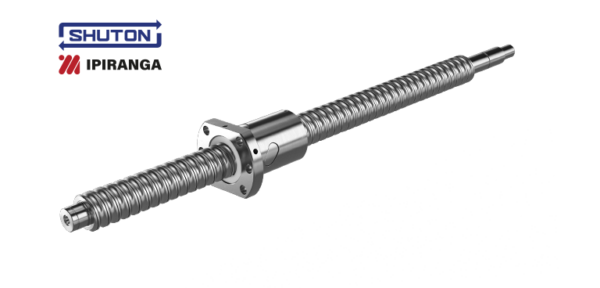

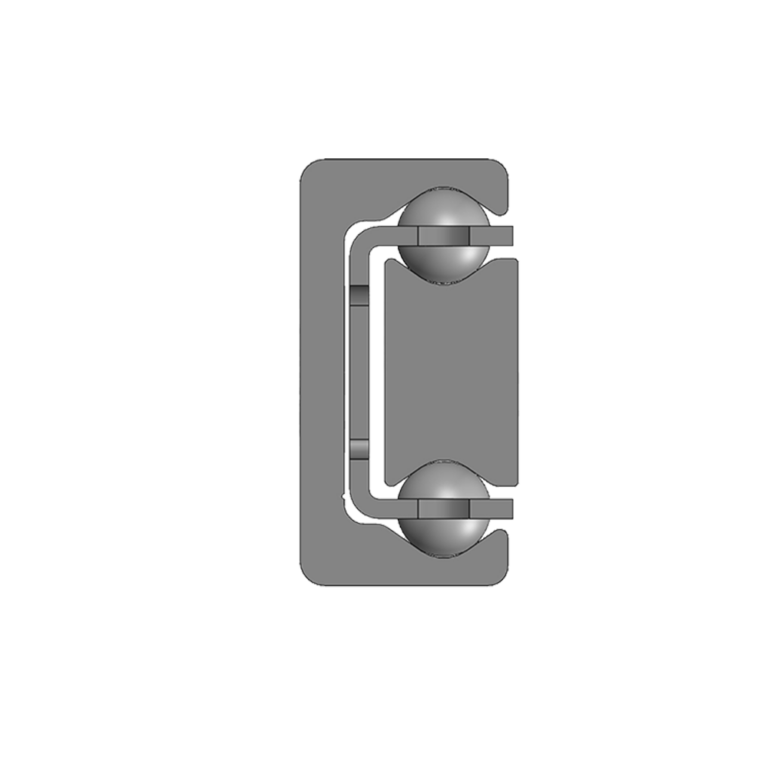

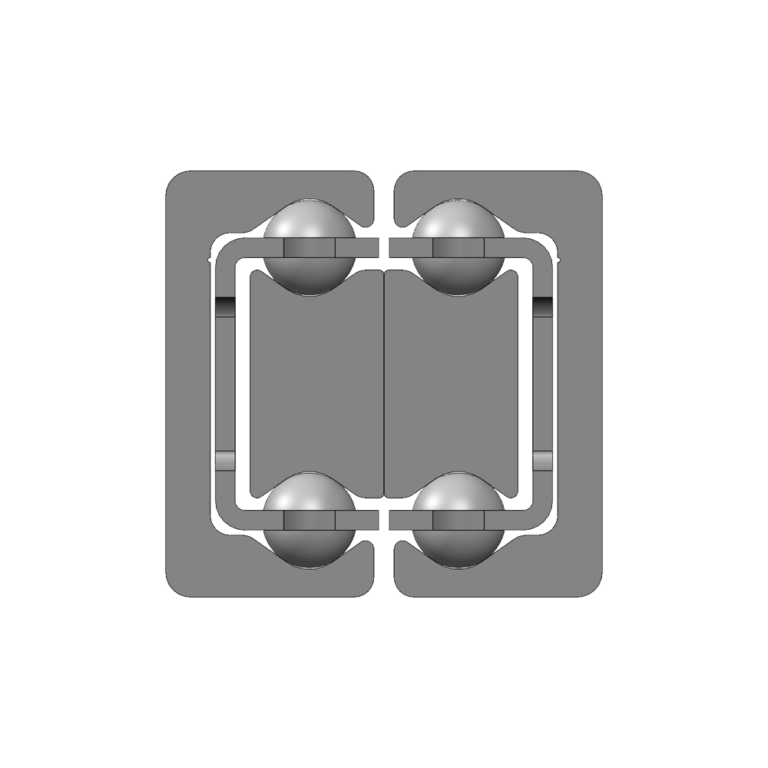

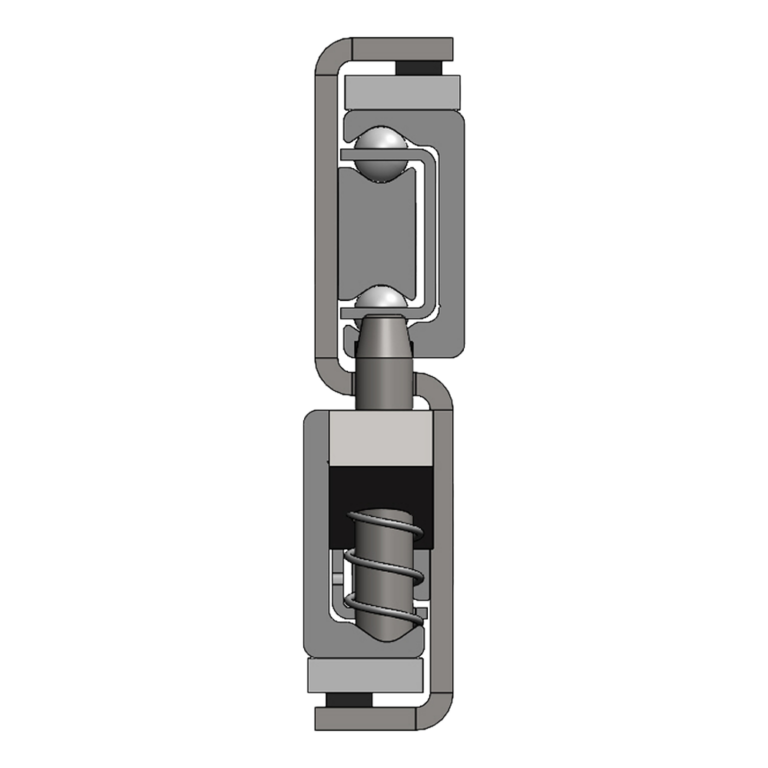

For recirculating ball style bearings such as our Mono Rail Plus, there are multiple surfaces and rows of ball bearings. Be sure to reference the catalog illustrations when you specify your bearing.

Our Mono Rail Plus’ running grooves are ground in a semicircular profile. Additionally, they have a 45-degree contact angle in 0 arrangement. This unique surface feature ensures the same load capacity in both the radial and axial directions.

Accurate Load Calculations Help You Select an Optimal System

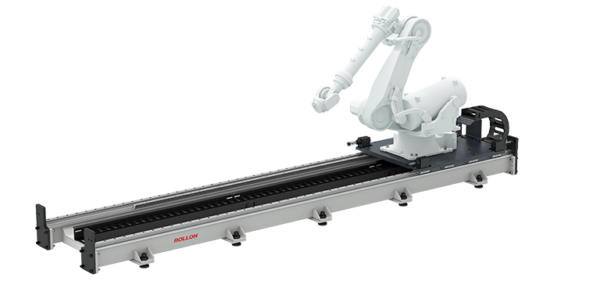

At Rollon, we have a full lineup of linear bearings designed to meet all of your needs. We are proud to provide a wide choice of sizes, styles and load-handling capabilities. But with so many options, it all starts with having a firm understanding of the differences between axial vs radial load ratings.

Having knowledge on your side will help you make accurate load calculations. This accuracy will ensure you get an optimal system that satisfies your needs. That’s why we’re here.

At Rollon, we have a team of professionals ready to walk you through the finer points about axial vs radial loads. They can help address any concerns you have and provide real-time insights and recommendations.

And if you have additional questions about axial vs radial loading, our team has you covered. Your local Rollon sales representative or regional engineer can answer them and assist you with sizing your application.