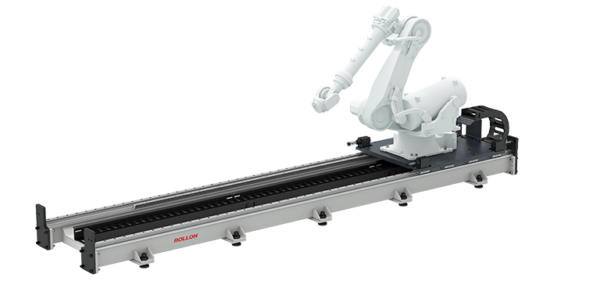

Vertical farming is a rapidly growing industry that offers planners and industrial designers various opportunities for development. Rollon’s solutions, designed for linear motion in demanding and challenging environments, can be utilized to create systems that are safe, reliable, and high performing.

Vertical farming, an innovative agricultural production concept, was first proposed in 1999 by Dickson Despommier, a professor of Public and Environmental Health at Columbia University. This system of vertical cultivation can be utilized in confined spaces, using less soil, to enhance the production of plant species while significantly reducing water consumption up to 80%. Additionally, there’s a specialized niche that involves breeding insects for producing alternative proteins, different from animal proteins. Insect farms adopt the same principle of vertical stacking to minimize space usage and maximize yield.

The rapidly expanding market in this domain is crucial for addressing the environmental and social challenges of our era and is projected to reach a value of $26 billion by 2026.

These cultivation methods, however, require the implementation of specific technological solutions to manage the unique climatic, environmental, and chemical conditions present within vertical farms. This is also true for linear motion, an essential component for applications in this sector.

Critical Issues to be Addressed for Handling

A vertical farm can be established in enclosed spaces like warehouses and industrial areas. It typically involves tasks such as transferring trays between stages, palletizing plant products, operating robotic systems for harvesting and planting in tanks, and gathering data related to the vertical farm and packaging processes.

Cultivation tanks, or breeding tanks for insects, are usually stacked vertically within metal frameworks that allow them to slide out for human intervention. The handling of these tanks and managing different applications within the farm’s structure present significant challenges for industrial designers. Challenges can include dealing with water and moisture, or the entry of contaminants like soil, debris, waste, and droppings (especially in insect breeding). Another critical factor is the use of special fats.

For effective handling, a combination of features is necessary to ensure full functionality under critical conditions while also providing resistance to corrosion and contamination. Additionally, the linear motion solutions must accommodate any misalignments between the fixed and moving parts of the structure. They must also guarantee smooth sliding and extraction of the tanks, even under varying load conditions.

The Rollon Solutions

Rollon provides specialized solutions for the unique applications and challenges encountered in vertical farming.

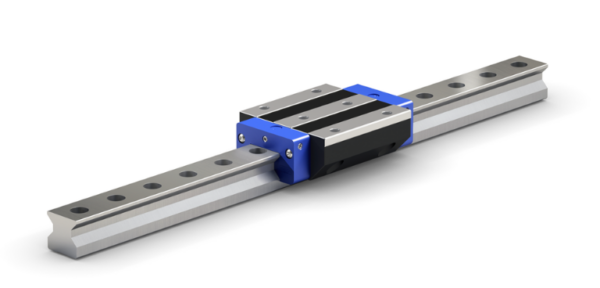

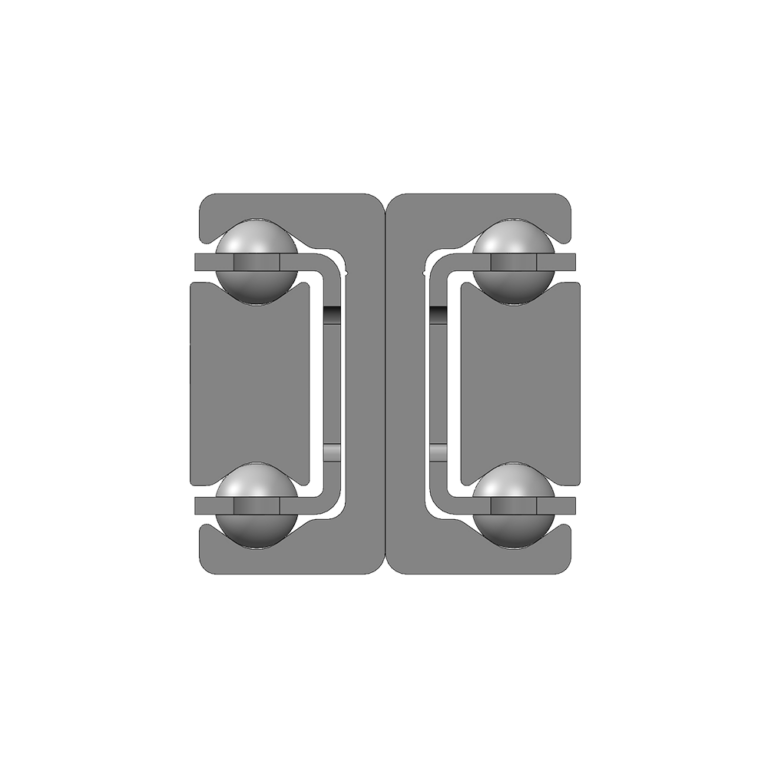

X-Rail Linear Rails: Reliability and Resistance to Environmental Impurities

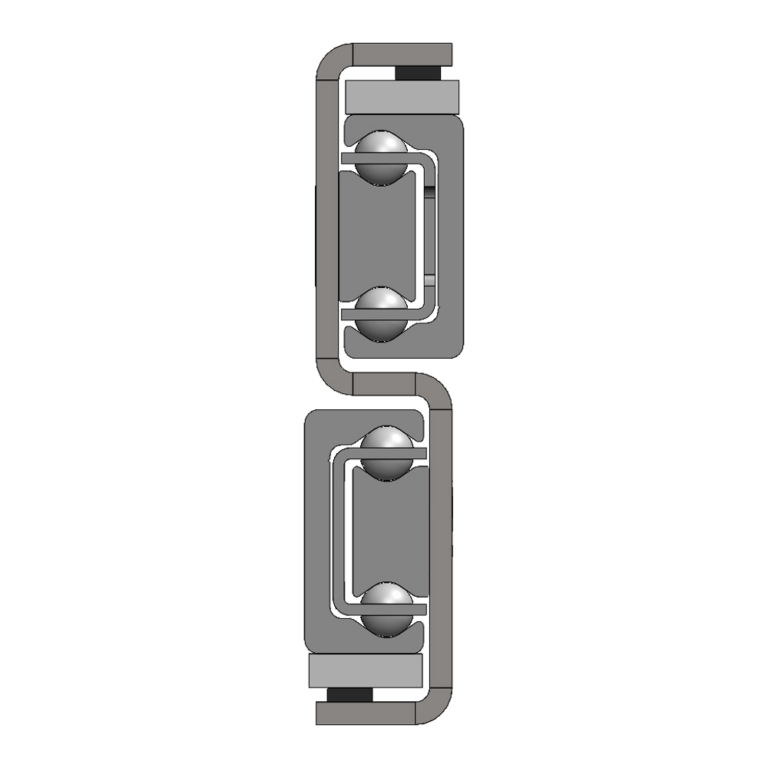

The X-Rail linear rails offer a dependable solution in environments prone to impurities. They feature rolling elements with shaped and flat raceways and are available in multiple variations: galvanized, nitride, or stainless-steel sheet metal. The stainless-steel version ensures complete corrosion resistance, crucial in the hostile environments typical of vertical farming.

The T + U configuration of the X-Rail linear rails stands out for its innovation. It is designed to compensate for parallelism errors in mounting surfaces, simplifying the installation process and reducing costs.

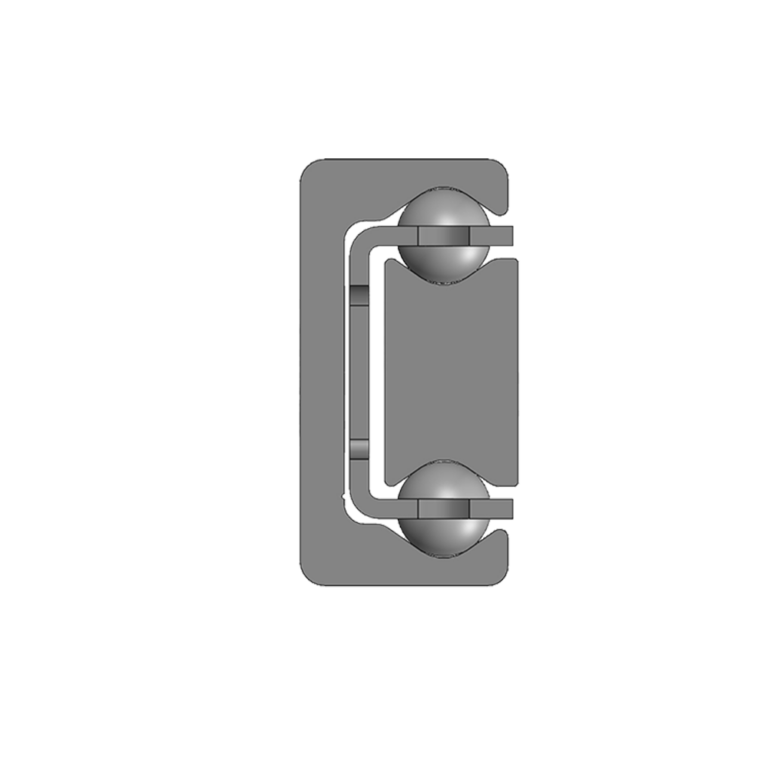

Compact Rail Plus: Performance and Versatility

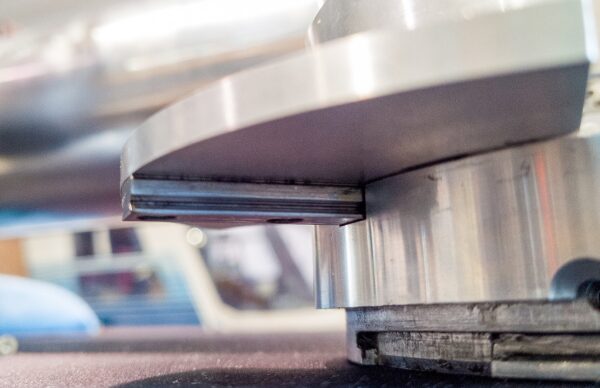

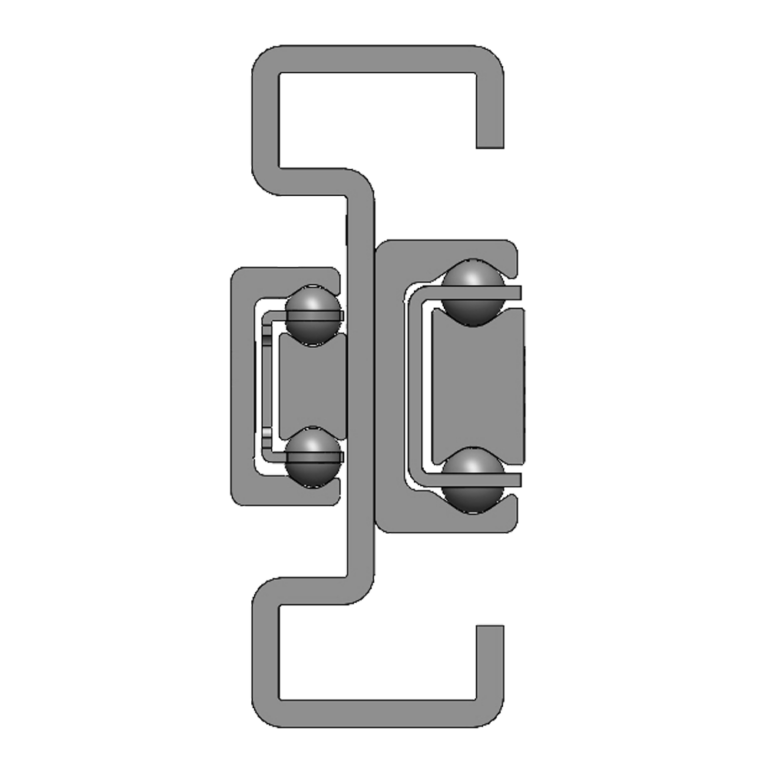

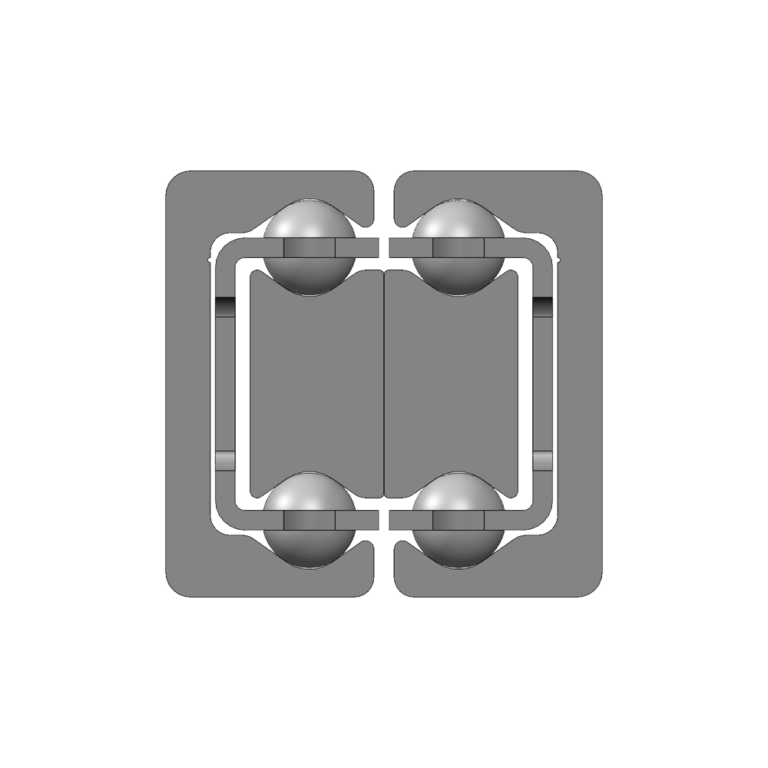

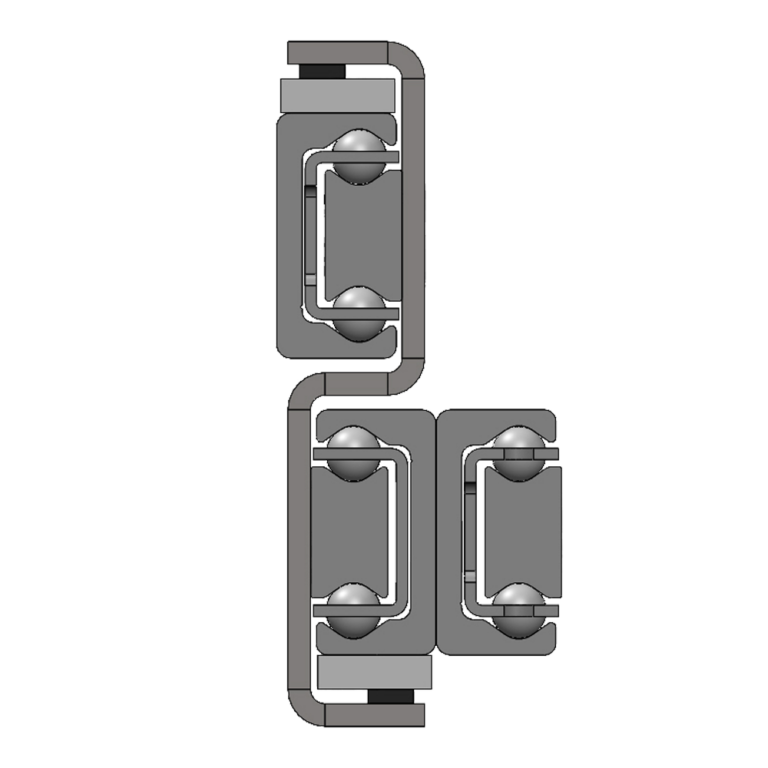

The Compact Rail Plus linear rail incorporates double-row ball and roller bearings featuring a “C” profile with convex, induction-hardened, and ground raceways in various sizes (18, 28, 43 mm). This design allows for handling up to 170% more load in the axial direction and up to 65% more in the radial direction compared to previous models, while maintaining the same overall dimensions.

It can accommodate significant axial misalignment of up to 3.5mm and radial misalignment of up to 1.3 degrees, which simplifies installation and reduces application costs. Additionally, the Compact Rail Plus is equipped with self-centering wipers for optimal cleaning of the raceways and a new integrated lubrication system that minimizes maintenance needs. These features make it particularly suitable for environments with a high risk of contamination such as in vertical farming.

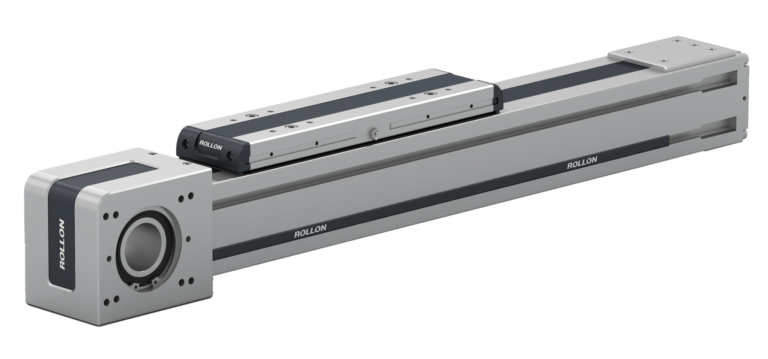

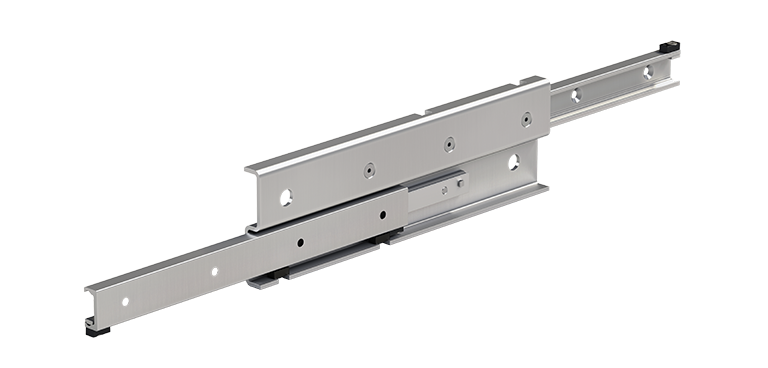

Telescopic Rail: Reliability in Challenging Conditions

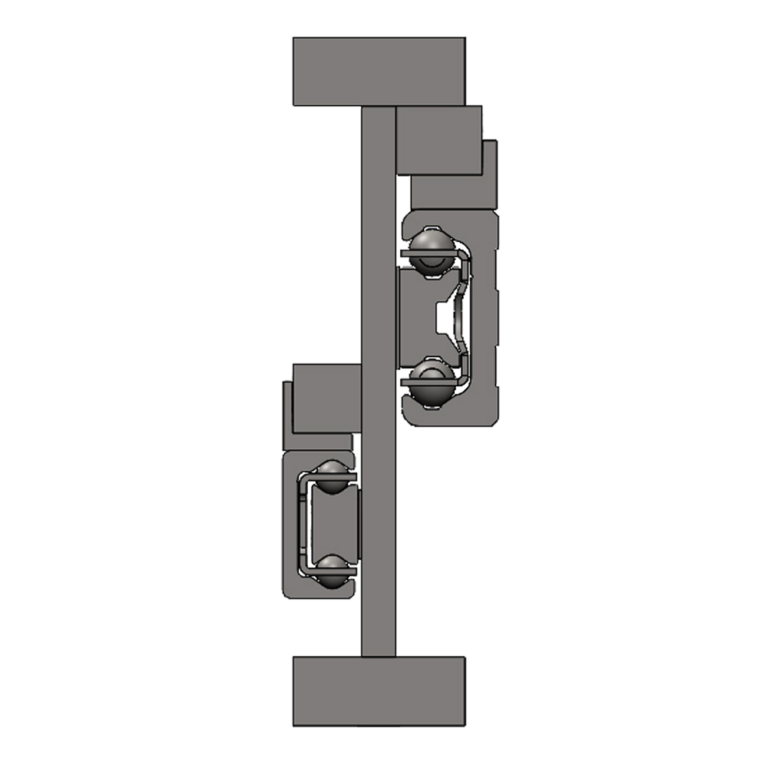

Industrial applications that require telescopic movements often operate in extreme conditions that test the durability and reliability of their solutions. These conditions may include heavy loads, contamination, and environments susceptible to oxidation and corrosion, necessitating the use of highly durable and reliable telescopic linear rails.

For such demanding applications and design challenges, Rollon offers the Telescopic Rail range, capable of supporting up to 3,800 kg per pair of rails. These telescopic rails can achieve partial or full extensions of up to 200% of the length of the rail in the closed position. The range is also equipped with a locking system and shock absorbers to enhance the safety of the application.

The rail profiles, treated for hardening, provide exceptional load capacity and are designed to maintain rigidity even when fully extended, with minimal flexing. This makes the Telescopic Rail range an ideal choice for applications where reliability is paramount, such as in environments with heavy loads and potential contamination, such as those found in vertical farming.

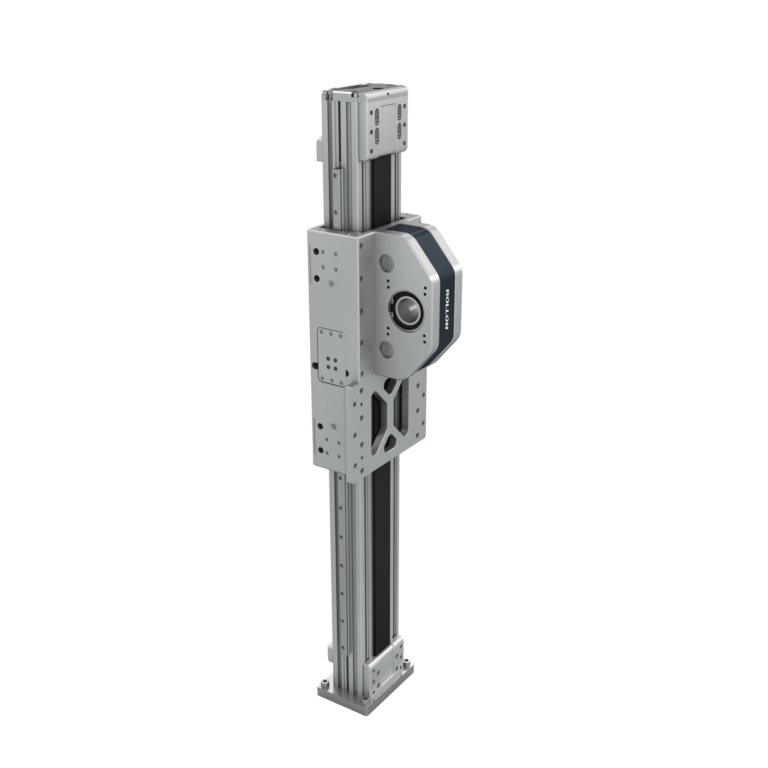

ELM: The Contamination-Proof Linear Axles

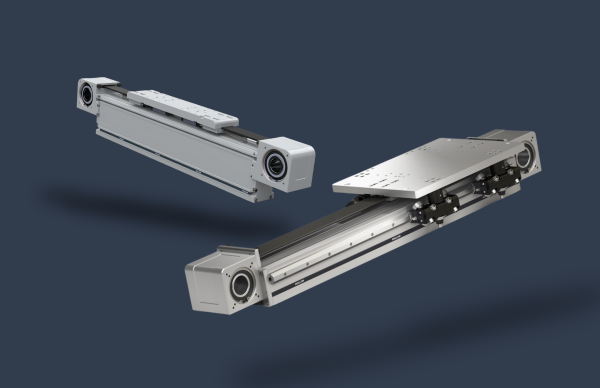

Rollon offers the Plus System range of linear axles. These axles are engineered for intricate movements in robotic systems, such as during the seeding or harvesting of plant species, as well as for monitoring and data collection using vision systems mounted on the robot’s wrist.

The Plus System is the Rollon range designed to provide maximum protection even in the harshest environments. This includes the ROBOT series actuators, and SC series actuators specifically designed for vertical movements.

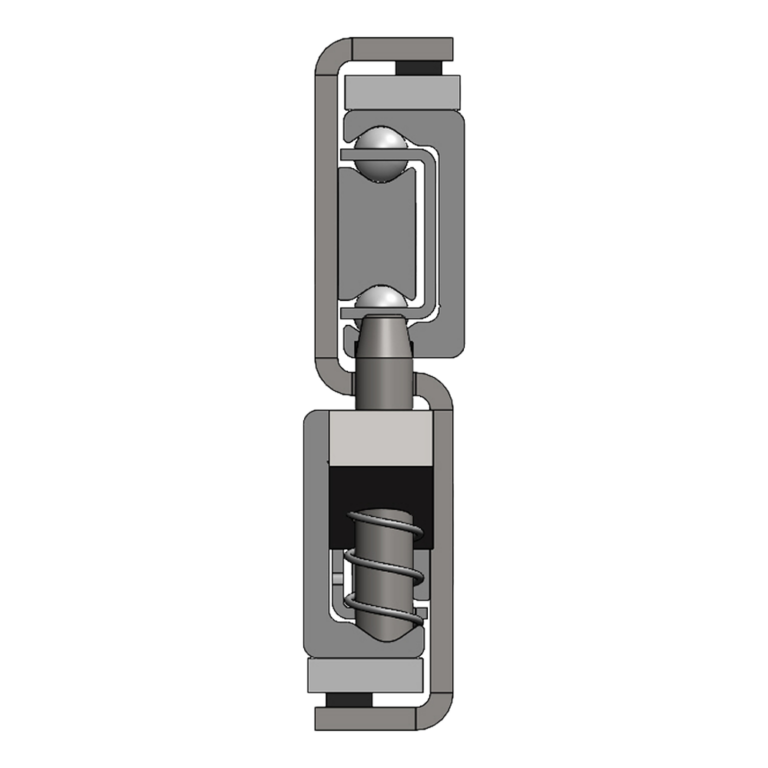

The ELM series linear actuator features a belt drive and extruded aluminum body. Notably, the linear recirculating ball bearing rail is integrated directly into the profile, making it exceptionally resilient against liquids and contaminants. An additional protective layer of polyurethane material seals the aluminum extrusion, effectively shielding the rolling elements from contaminants and liquids. Furthermore, ELM series axles can be pressurized, ensuring outstanding sealing with minimal air/energy dissipation. These axles are also compatible with special food-grade lubricants, enabling their use in farming for the product of food intended for human consumption. This versatility and resistance to contamination make ELM series axles a valuable choice for a wide range of applications, including vertical farming.

Rollon is a trusted technology partner for companies seeking to invest in the thriving vertical farming market. We provide customized solutions designed to address the unique challenges of this emerging industry. Our cutting-edge technologies play a pivotal role in the creation and upkeep of dependable and secure linear motion systems that align with industrial standards. Additionally, Rollon’s offerings can be tailored to meet the specific requirements of individual applications.

For further information, contact our experts: https://prod-rollon.rollon.com/usa/en/#ask-rollon