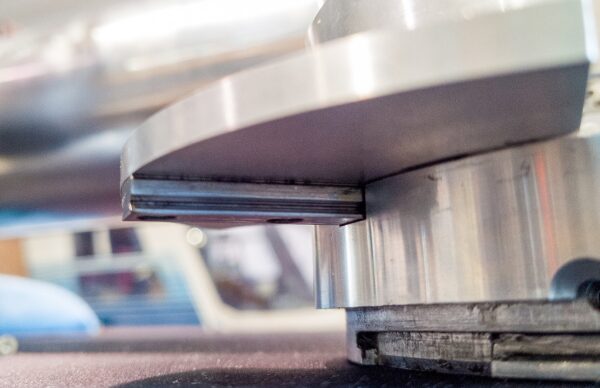

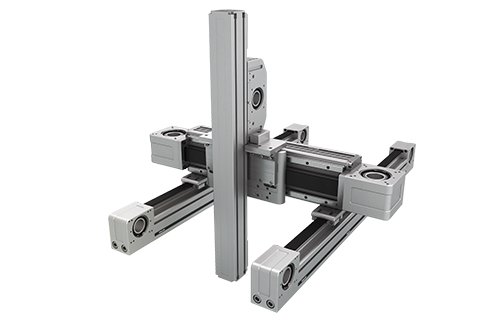

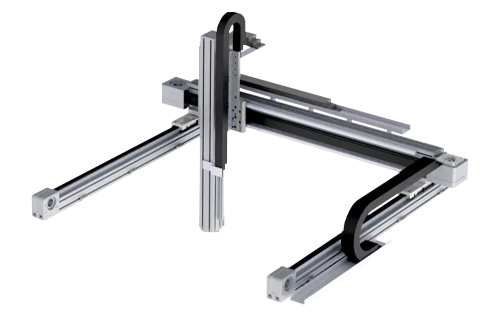

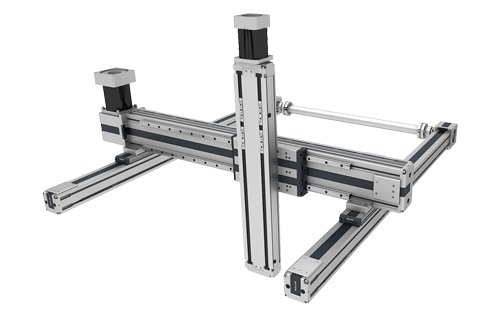

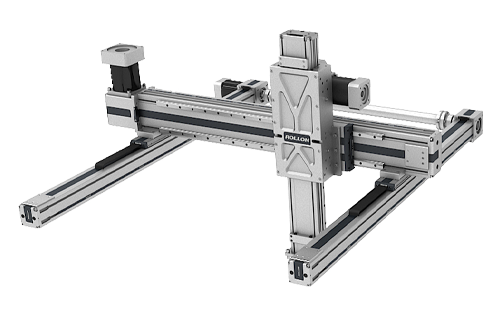

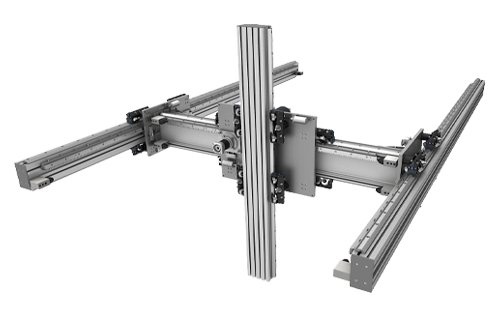

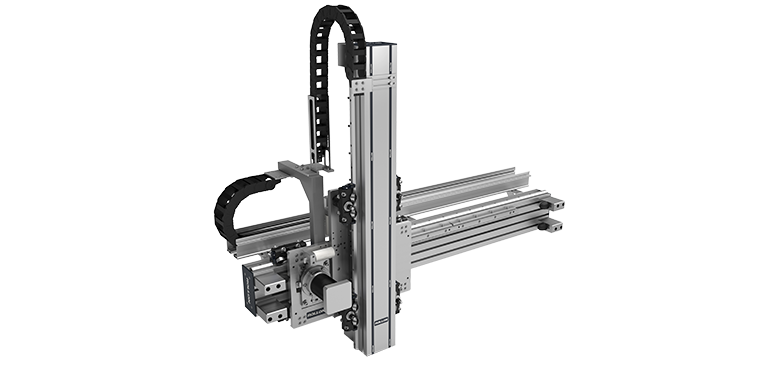

Off-the-shelf robots for injection molding parts removal tend to be more expensive and less flexible than those made in-house. For this reason, Stone Plastics & Manufacturing Inc. makes its own customizable robots for manufacturing plastic parts, allowing them to serve more industries and control costs.

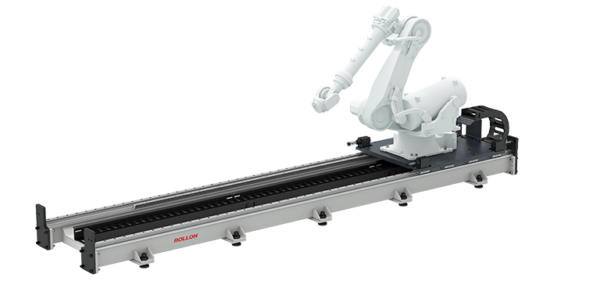

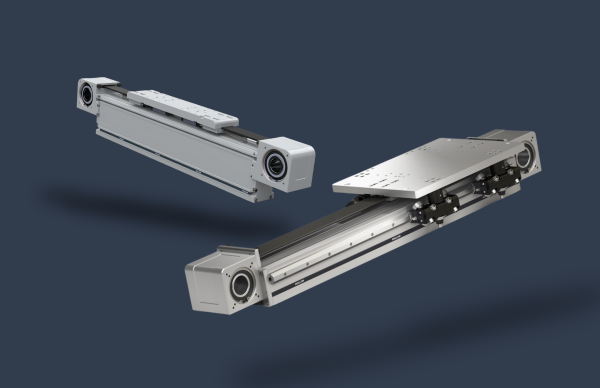

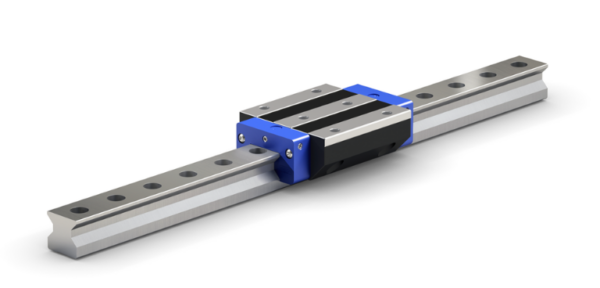

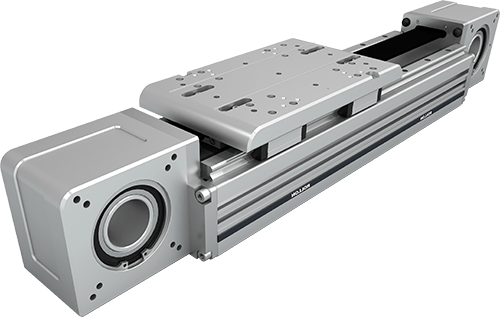

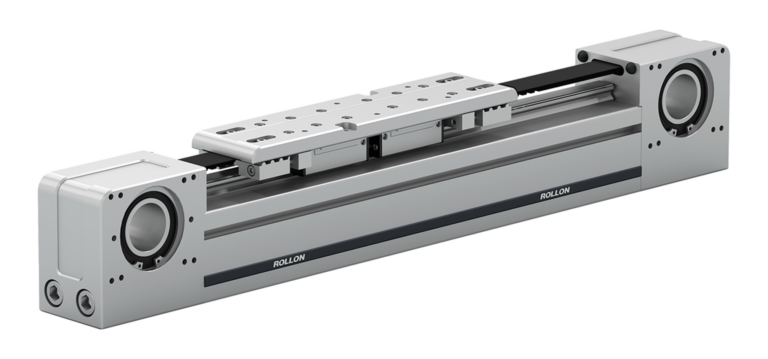

For linear motion in their robots, Stone Plastics uses Rollon actuators. Check out our latest case study to learn about the role our actuators play in unloading plastic parts from injection molds.