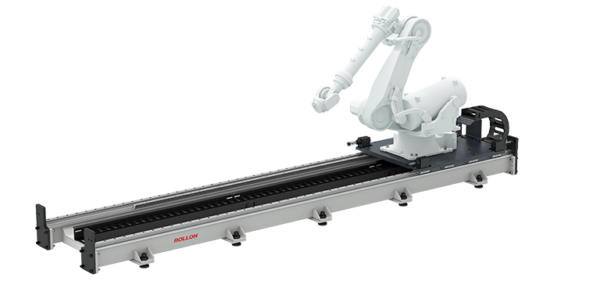

In a recent video, Rollon engineers detail how a pragmatic assessment of a design’s alignment needs can often make for a more cost-effective design.

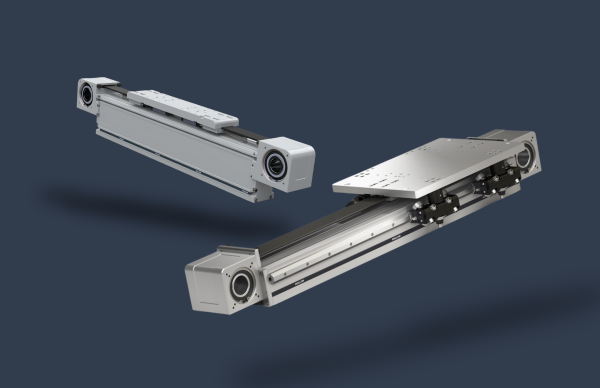

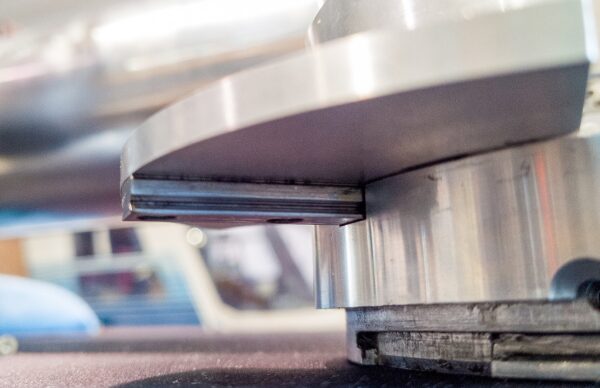

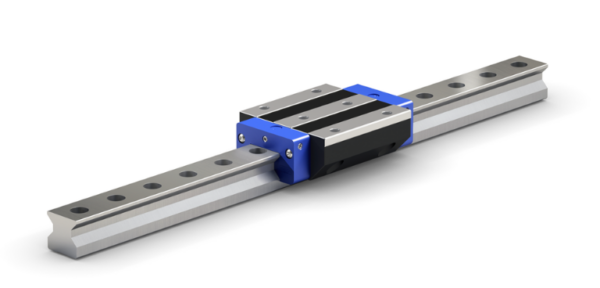

In contrast with precision linear motion-control applications, designs to simply transport workpieces and other objects are more forgiving of misalignment. That’s why profile-rail linear guides are often overkill (and unjustifiably costly over the life of the linear component) in transport applications. More suitable are Rollon Compact Rail products.

This video compares the cost of using Rollon Compact Rail products to the cost of using Telescopic Rail and other telescoping linear bearings for a given design. The alignment capabilities of these two product lines are also compared as are the way in which these products are adjusted to reduce misalignment.