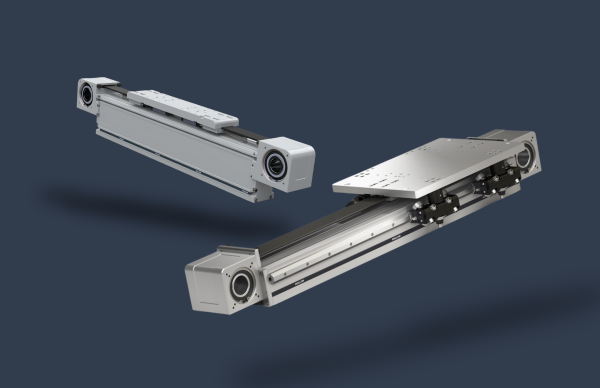

A linear actuator is a self-supporting structural system capable of transforming a circular motion into a linear motion. This motion is generated by a motor, and sends the movement (or force) along an axis. In this way, linear actuators operate differently than conventional electric motors, which work in a circular motion.

This greatly helps to produce movements such as the pushing, pulling, raising, lowering or inclination of a load. And because of this, there are various linear actuator types. And as you can imagine, not all of them do precisely the same thing. Let’s break down some of the common linear actuator applications.

What is a Linear Actuator Used For?

Not all types of linear actuators are the same, but they generate a similar linear movement with power. On one hand, linear actuators move objects or items in a straight line. But to take that further, they complete this motion with precision and great speed.

This converted rotary motion generates an incredible amount of efficiency for the task at hand, and the production overall. But one type of linear actuator might be better suited for your needs than another. This all depends on your processes, and what materials you are in need of moving.

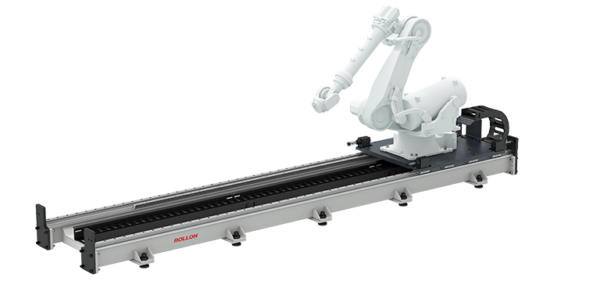

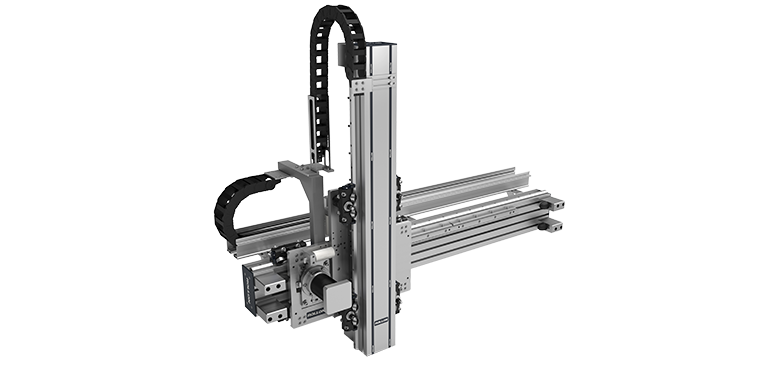

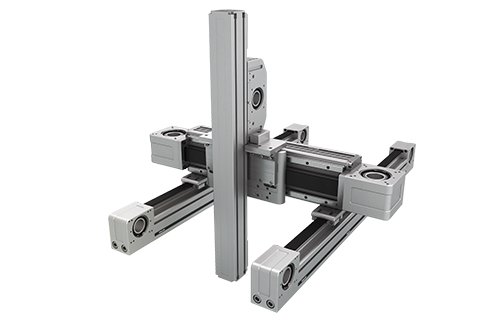

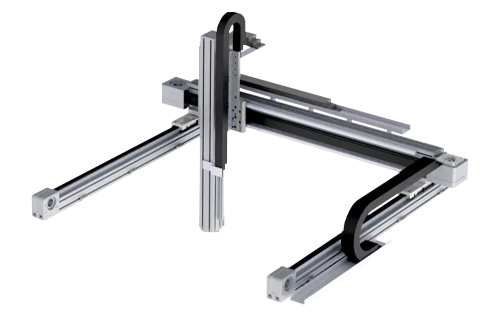

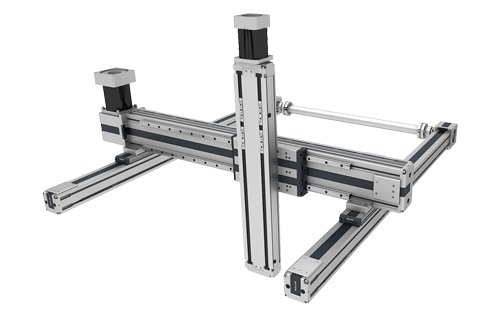

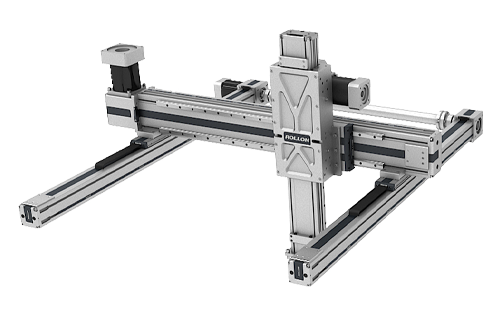

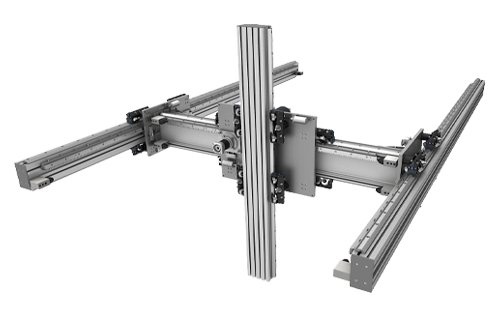

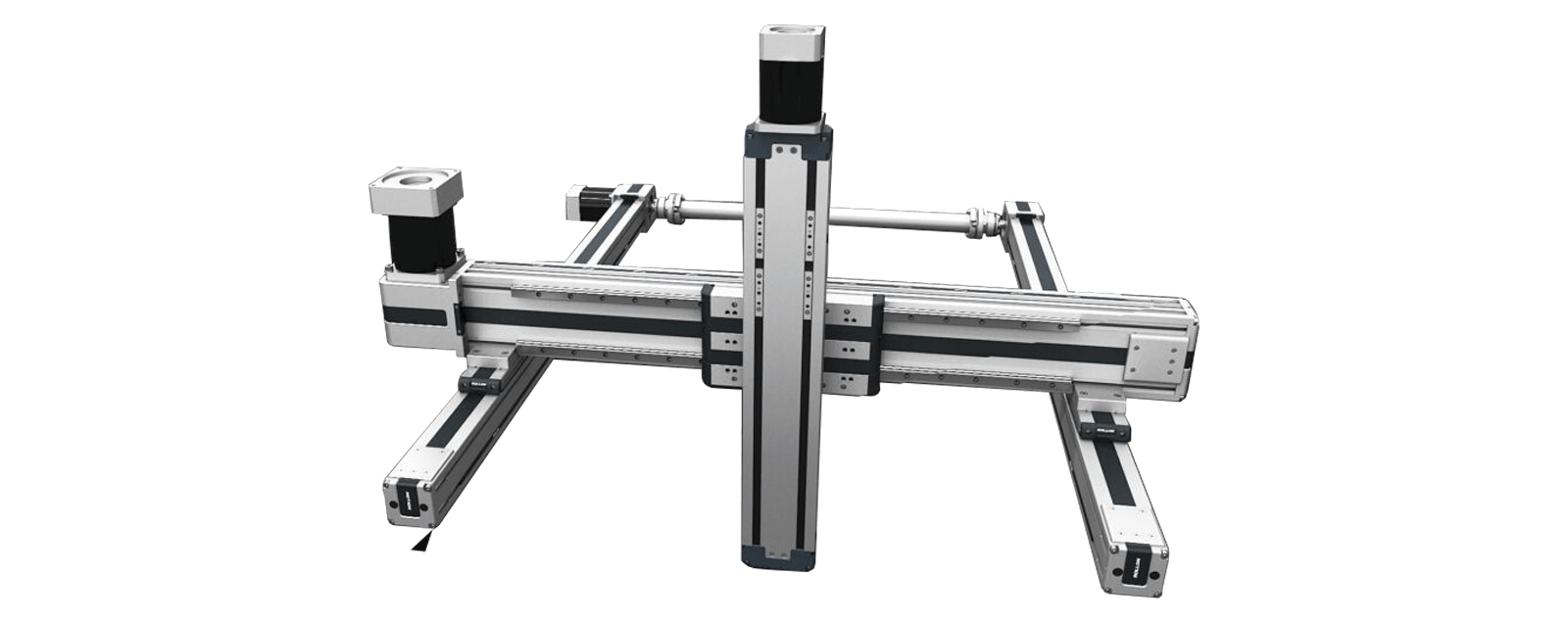

The most common use of actuators involves combining them with multi-axis Cartesian robot systems. It is also popular to use them as integral components of machines.

The main sectors:

There are all sorts of industries that can make use of an electrical linear actuator. Whether you have a small operation, or are moving a significant amount of material every day. The point is that whatever your operation entails, there is a linear actuator ideal for you.

Therefore, the below list is by no means a complete list of sectors, just some of the more common examples. It is clear to see why these sectors benefit from controlled and precise linear movement.

- industrial automation

- servos and pick-and-place systems in production processes

- assembly

- packaging and palletisation

Indeed, just think of applications such as

- laser or plasma cutting machines

- the loading and unloading of machined pieces

- feeding machining centres in a production line

- or moving an industrial anthropomorphic robot along an additional external axis in order to expand its range of action

All of these applications use one or more linear actuators. The type of linear actuator used depends on various factors, such as: precision, load capacity and speed. Overall, it is typically the type of motion transmission that makes the difference.

There are three main types of motion transmission:

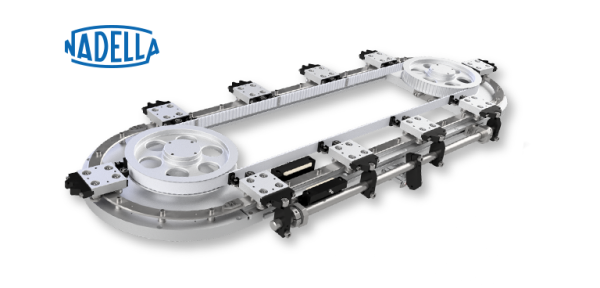

- belt

- rack and pinion

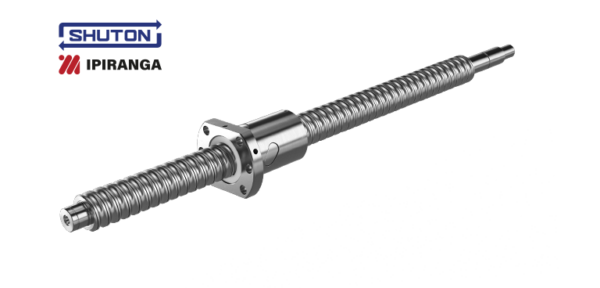

- screw

How can you ensure that you choose the right actuator? What variables does an industrial designer tackling a new application have to take into consideration?

When talking about linear motion solutions, the important thing is to consider the issue from the right viewpoint. Specifically, this means the application at hand. This is always first and foremost when deciding the type of linear actuator you need.

And secondly, list out all the results and performance you are expecting. Those will help you tailor your linear actuator to your precise needs. Now you have the type of linear actuator you need, and the specifications you require.

As such, it is worth starting by considering the dynamics, stroke length and precision required.

Let’s look at these in detail.

High Dynamics

In many areas of industrial design, the demands of the designer often have to do with speed. They typically include reducing cycle times as well. A good example of this is the packaging industry. After all, the more precise and speedy the packaging, the faster the packages are going out the door.

It is no surprise, then, that high dynamics are commonly the starting point when defining a solution.

Belt drives are often the ideal solution when it comes to high dynamics, considering that:

- they allow for accelerations up to 50 m/s2 and speeds up to 5 m/s on strokes as long as 10-12m

- an X-Y-Z portal with belt-driven axes is capable of handling loads ranging from extremely small to approximately 200kg

- according to the type of lubrication, these systems can offer particularly long maintenance intervals, thus ensuring continuity of production.

There are times when high dynamics are required on strokes longer than 10-12m. In these instances, actuators with rack and pinion drives tend to be an excellent solution. This is because these linear actuators allow for accelerations up to 10 m/s2 and speeds up to 3.5 m/s. And all of this on potentially infinite strokes.

Rack and pinion actuator models implement the concept of a wheel and axle. Specifically, a rotating wheel moves a cable, chain, or belt to produce linear motion.

The choice of a different type of actuator would not guarantee the same results. A screw system, for instance, which is undoubtedly much more precise, would certainly be too slow. With such an actuator, you would not be able to handle such long strokes.

Though a screw actuator is an incredibly common tool, rotating the screw in order to drive it forward. However, it has limitations to speed depending on your scenario.

Long Strokes

Systems created by linear actuators in the typical X-Y-Z configurations of Cartesian robotics often have long strokes. This is common in applications such as pick-and-place and feeding machining centres. Because of these long production lines, the strokes can often reach dozens of metres in length.

Plus, in many cases, these long strokes – which usually involve the Y axis – are tasked with handling considerably heavy loads. In some instances, the loads can often weigh hundreds of kilos. Additionally, numerous vertical Z axes operate independently on these longer strokes.

In these types of applications, the best choice for the Y axis is an actuator with a rack and pinion drive. This is due to various factors, such as:

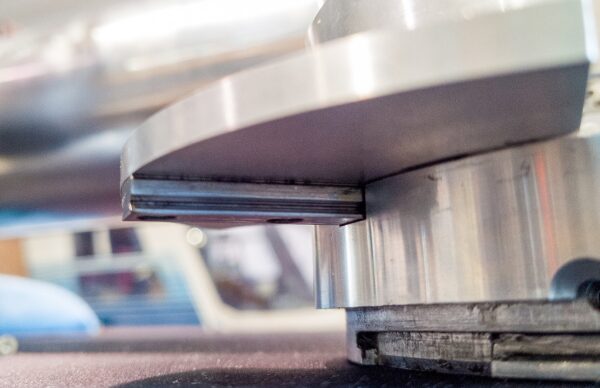

- Thanks to the rigidity of the rack and pinion system, they are capable of operating along potentially unlimited strokes. Meanwhile, they can function while maintaining their rigidity, precision and efficiency

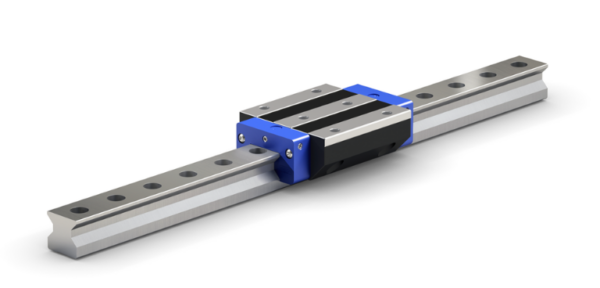

- Within the drive, actuators with induction-hardened steel racks have inclined teeth. These teeth slide along recirculating ball bearing rails or prismatic rails. And these bearings are capable of handling loads of over 1000kg.

- The option of installing multiple carriages, each with its own motor, allows for numerous independent vertical Z axes.

A belt system is ideal for strokes of up to 10-12m. And yet ball screw actuators are limited (in the case of long strokes) by their critical speed.

Positioning Repeatability

There are times, on the other hand, when the designer is seeking maximum precision. This might be the case in applications such as the assembly of microcomponents or certain medical field applications. In these instances, there is only one clear choice: linear axes with ball screw drives.

Screw-driven linear actuators offer the best performance from this point of view. This is largely because they have a degree of positioning repeatability as high as ±5 μ. This performance cannot be matched by either belt-driven or screw-driven actuators. Both belt-driven and screw-driven linear actuators reach a maximum degree of positioning repeatability of ±0.05 mm.

If you would like to learn more about this topic, then you are in the right place. Find out the nine essential features to consider when choosing linear actuators by downloading our white paper below. Or, contact us to learn more.