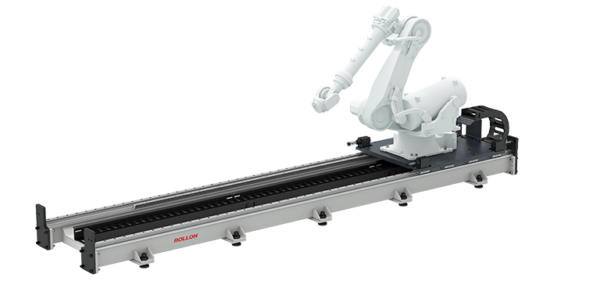

Aluminum can help a designer create an optimal configuration for a multi-axis system. It can also perform where welds and contaminants threaten service life. Rollon’s Speedy Rail self-aligning structural rails take advantage of aluminum’s distinct properties to provide greater design freedom for harsh automotive industry and packaging applications as well as many processing operations.

The Speedy Rail

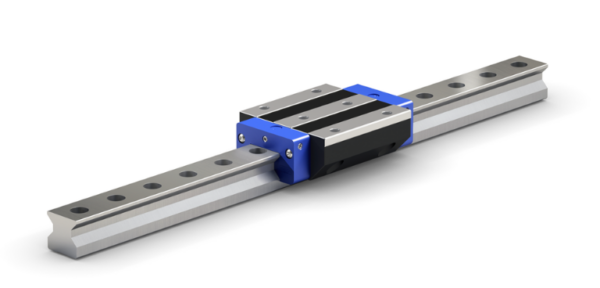

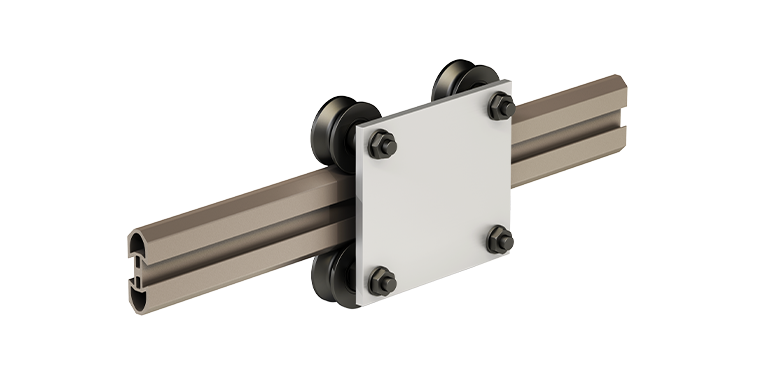

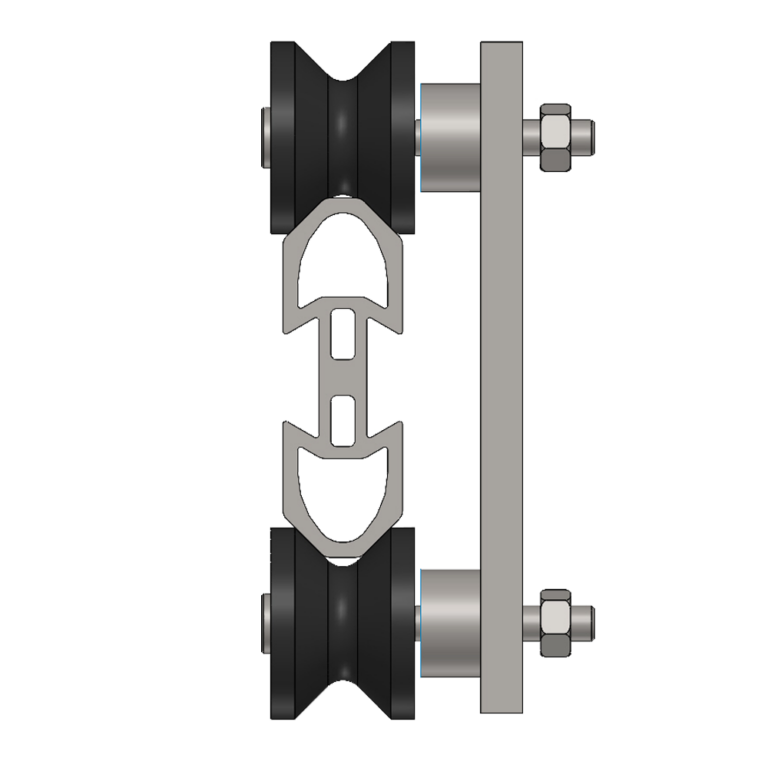

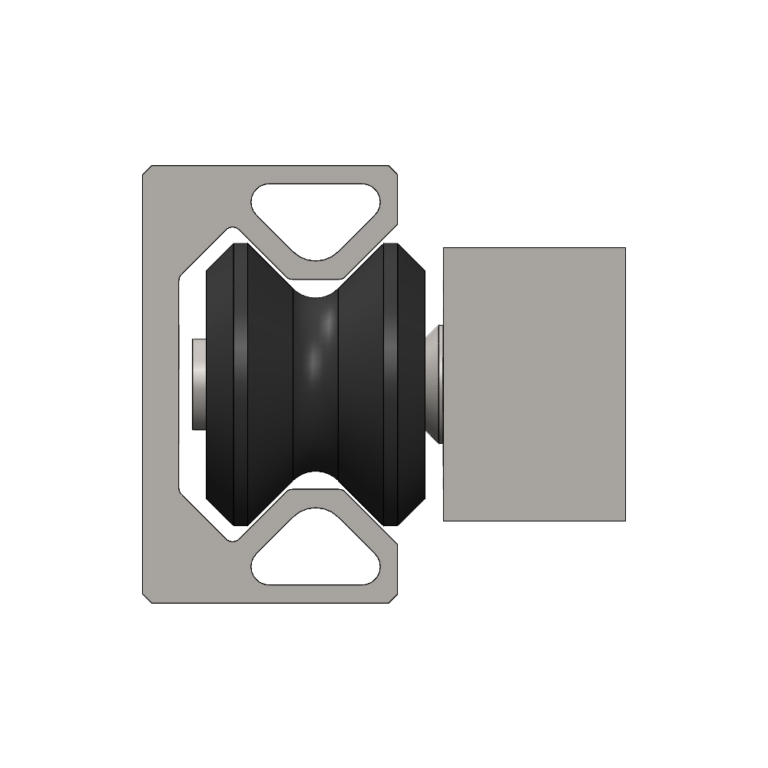

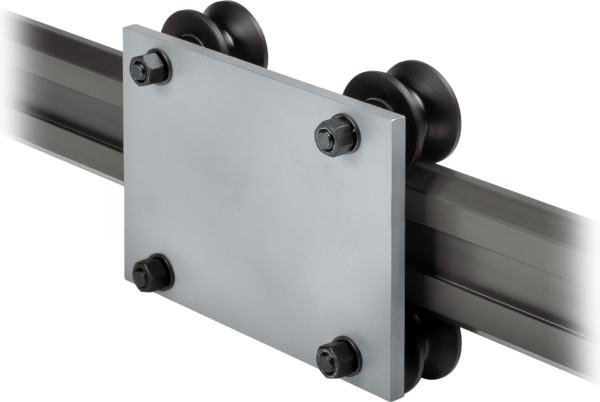

Speedy Rail consists of both a structural and a sliding system. The guide combines hard anodized extruded aluminum profiles with steel bearings coated in plastic. This construction provides a host of benefits that can make it an attractive choice:

- Self-supporting. Speedy Rail’s aluminum profiles are designed to exhibit a high moment of inertia. They provide the frame for the sliding system so additional support is unnecessary. For example, a stand-alone walking beam design may be used to carry pieces like car bodies or large appliances. Since extra support pieces do not have to be designed and built for the unit, designers can save money.

- Lightweight. Aluminum profiles make Speedy Rail lighter and easier to mount than steel rails. The system is particularly suitable for applications with tight weight requirements.

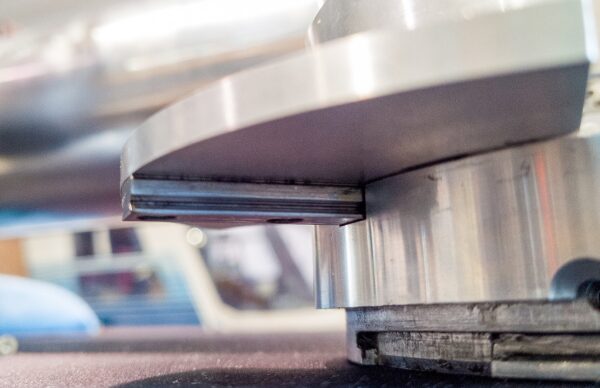

- Weld Resistance. Speedy Rail is also desirable for weld applications. A special coating on Speedy Rail’s aluminum resists weld spatter by increasing the fusion temperature higher than that of the weld. The plastic rollers then “flake” off the weld spatter as they pass over the rail.

- Corrosion Resistance. Because aluminum oxidizes naturally when in contact with air and is not altered by humidity, it resists corrosion and does not require any other treatment.

- Sealed. The rollers on Speedy Rail are sealed and lubricated for up to 80,000 kilometers to outlast the life of most automation equipment. The sealed system also resists forms of contamination that can cause other systems to fail. Designers can save time and money since they can avoid additional protection and lubrication measures.

Not only does the aluminum construction and surface treatment make Speedy Rail desirable for heavy duty industrial automation applications, it also provides these high-performance features and benefits:

- High load capacity. Speedy Rail can handle loads higher than 3,000 kilograms for gantry configurations with four sliders and eight rollers.

- Self-aligning. The system is capable of controlling misalignment to ± four millimeters. For parallel rails, the rollers and supports compensate for parallelism errors up to eight millimeters.

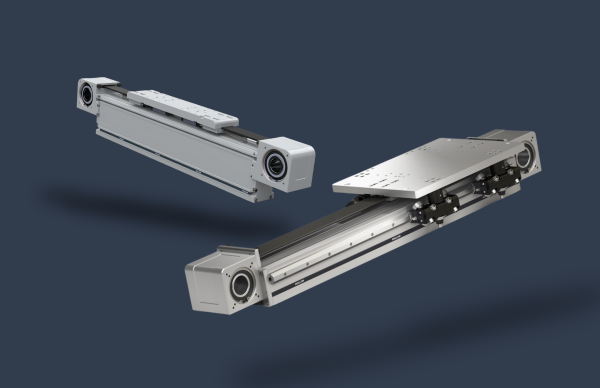

- Flexible. Speedy Rail can be used as a linear rail or actuator.

- High dynamics. Depending on the application, velocity = 15 m/s and acceleration = 10 m/s^2.

- Quiet operation. The plastic compound in Speedy Rail’s rollers ensures quiet operation.

- Customizable. Speedy Rail can be customized if needed.

A Self-supporting System That Meets Automation Needs

When it comes to linear motion in automated environments, productivity typically rests on the quality of the motion system’s construction. Rollon’s Speedy Rail’s aluminum profiles create a self-supporting system with exceptional load capacity which is also lightweight, easy to mount and is able to resist contamination and welds. The result: a high-performance, durable and nearly maintenance-free system that gives designers the freedom to address the needs of automated applications that can otherwise challenge traditional linear motion products.

For more information about self-supporting Speedy Rail, visit our product page.