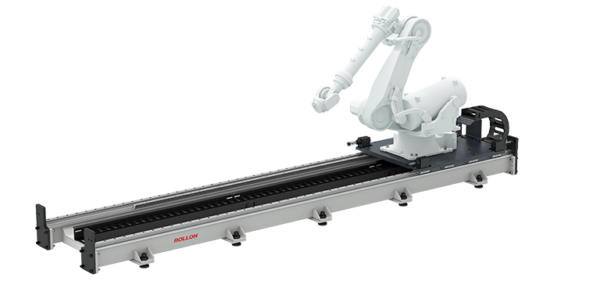

Rollon Telescopic Rail moves 2,500 pounds of cantilevered materials and machine to mold helicopter parts.

Aerospace manufacturers are increasingly turning to carbon fiber in their quest to make aircraft lighter and more fuel efficient. While composite materials offer many advantages including an attractive strength-to-weight ratio, conforming carbon fiber into large, complex parts is a difficult process.

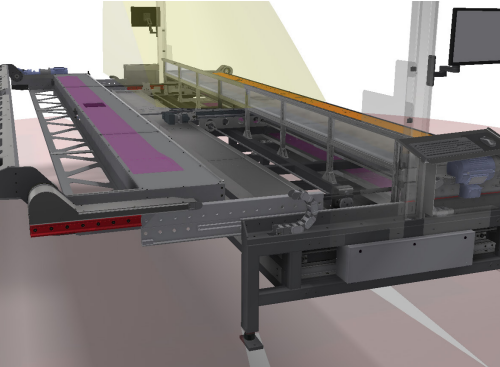

Recently, a large aerospace manufacturer asked Criterion Manufacturing Solutions, a custom manufacturing equipment specialist, to create a carbon fiber drape former in order to build interior supports for helicopters. As the structural parts of an aircraft become larger and more complex, the machines that form them also increase in size and complexity — especially when it comes to transporting heavy loads. For this large support part, the fiber drape former incorporates a layup table for stacking the carbon fiber plies into the correct orientation before they transfer to the machine’s tooling section. This arrangement will determine the strength and stiffness of the carbon fibers. In addition to the carbon pieces, the layup table also holds a vacuum apparatus which helps mold the plies.

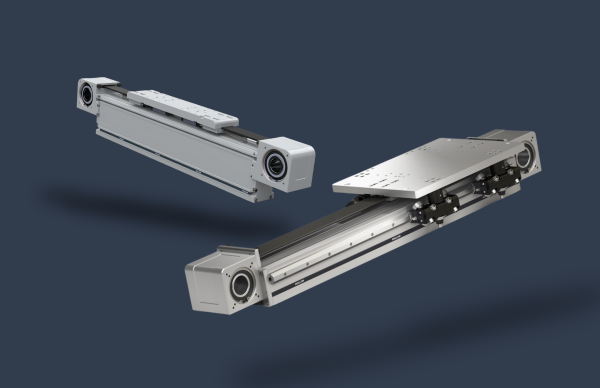

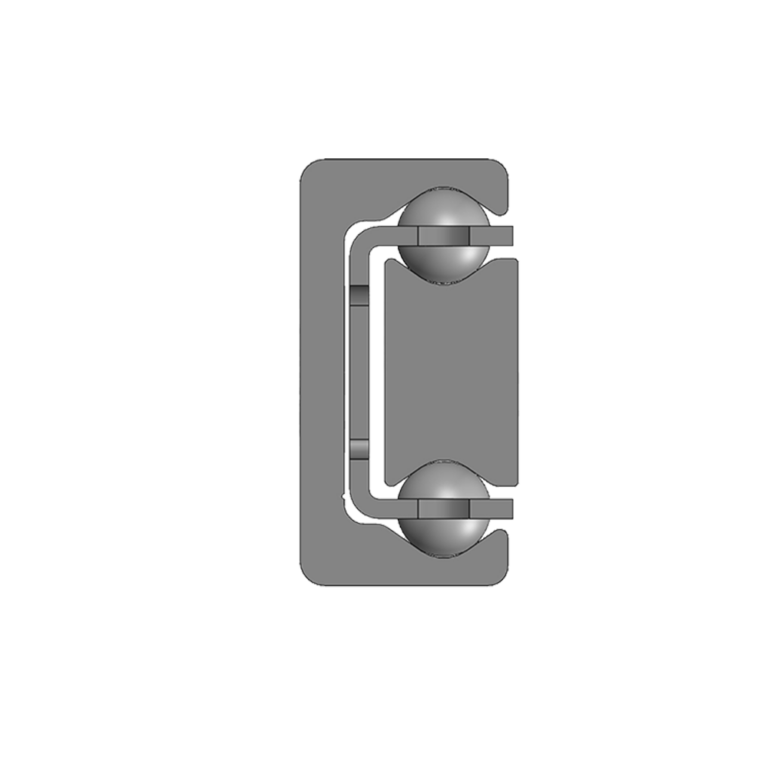

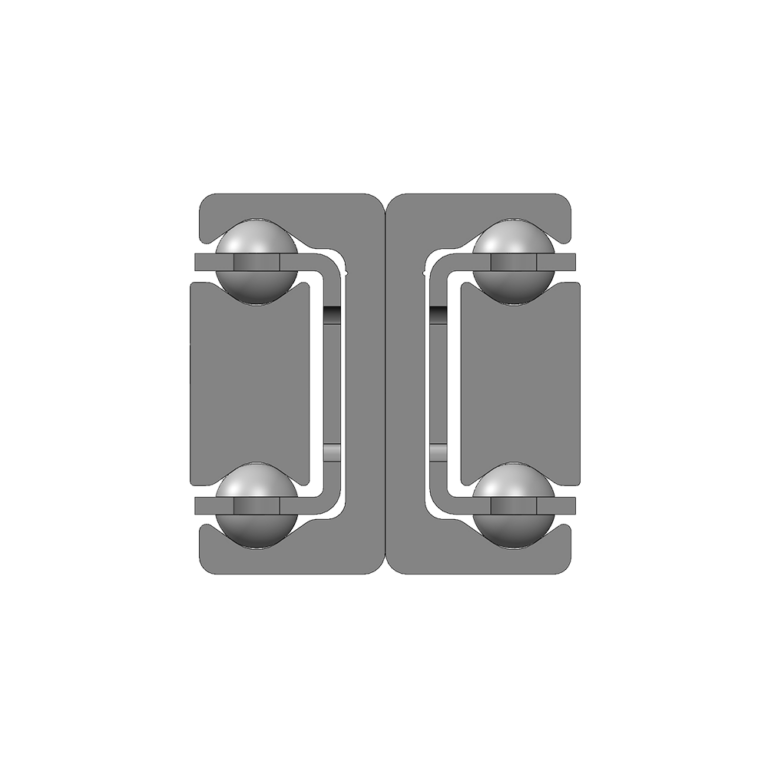

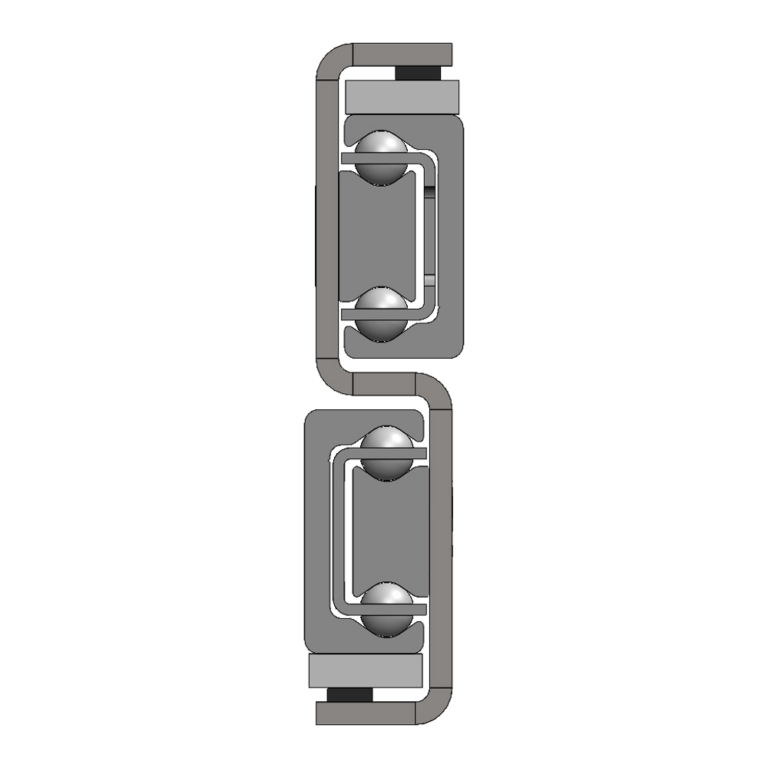

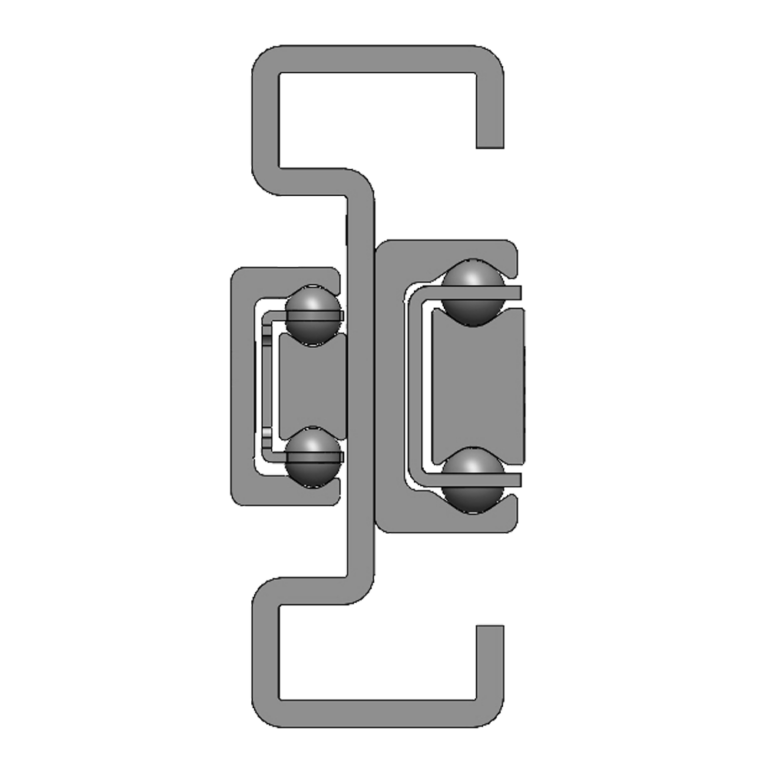

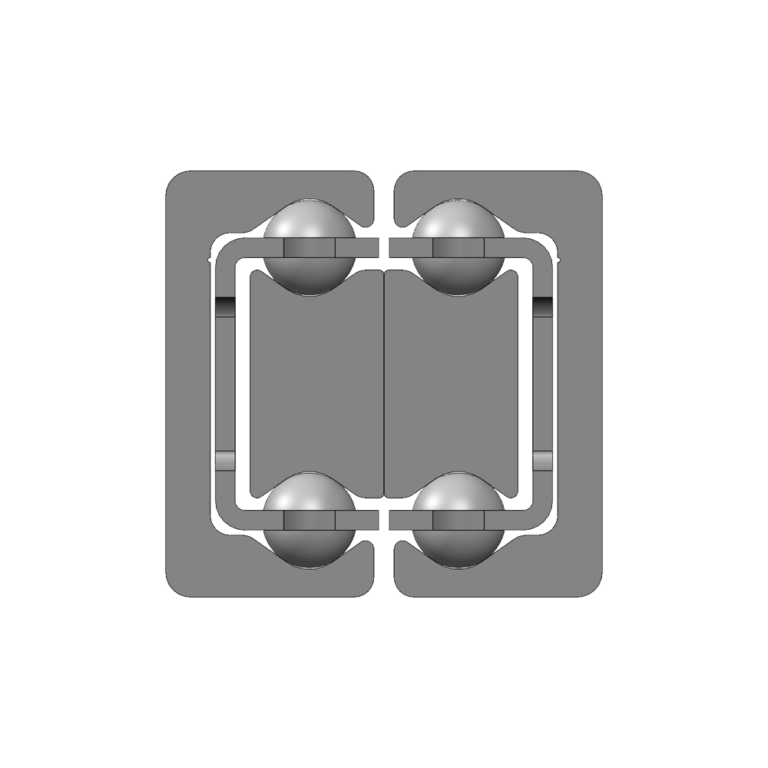

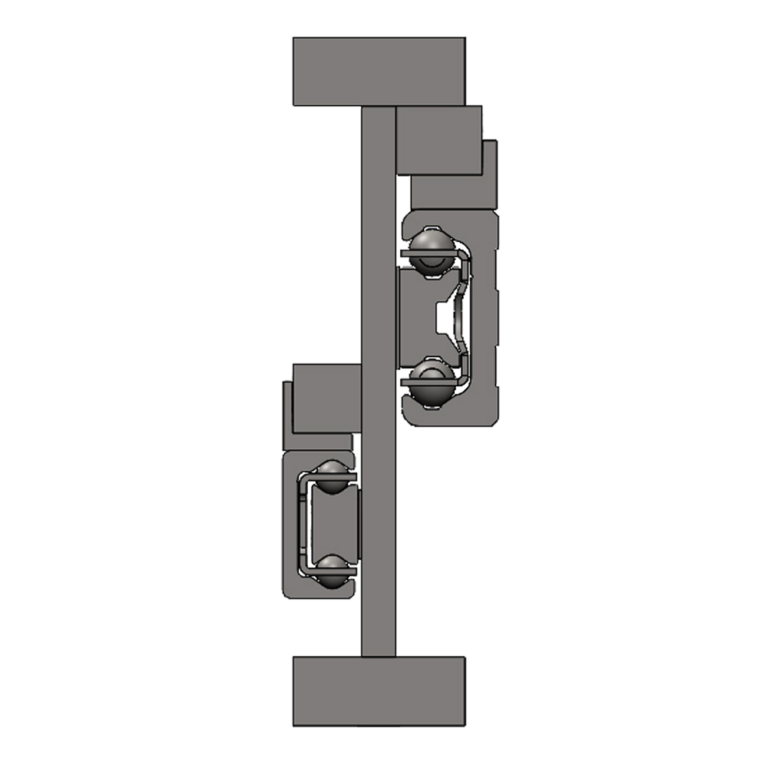

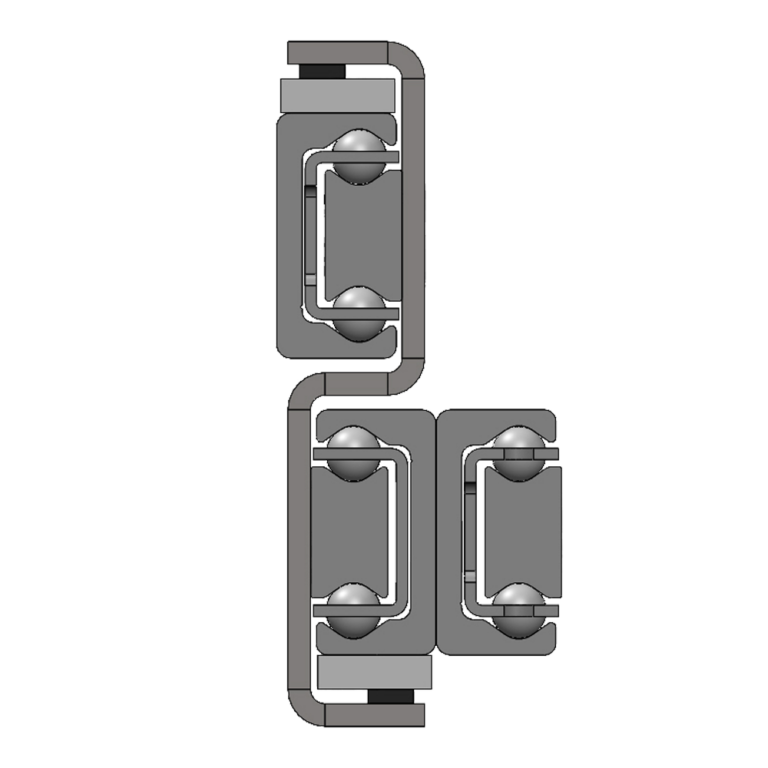

Rollon Telescopic Rail features high load capacity, low deflection, long extension lengths and a long operating life.

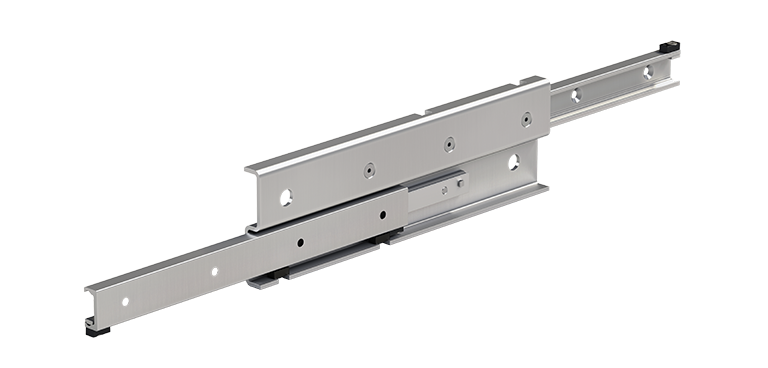

Criterion designed the carbon fiber drape former so that an operator will arrange 150 pieces of carbon fiber in sequence onto the layup table. Those carbon fibers, along with the 25-foot-long table top made of steel and aluminum as well as the vacuum, require a 46-inch shuttle to the tooling portion of the drape former. Once moved, the carbon fibers are heated, cured and joined together to form a large tube.

This complex transfer of materials and machine created several challenges:

- The entire load weighs approximately 2,500 pounds.

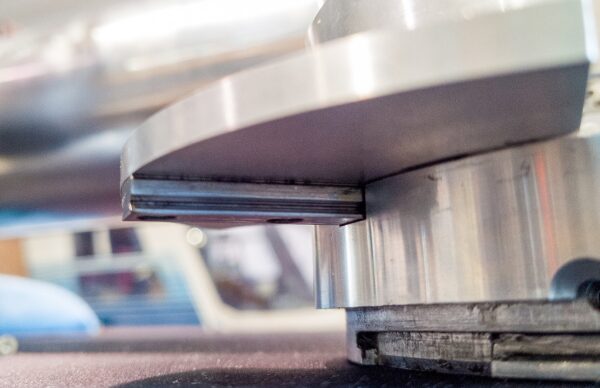

- The top half of the table will rotate and extend forward 16 inches past the edge of the table, creating a cantilevered load.

- The carbon fiber product has to be placed in the same location every time. The table has to deliver the load to the same place every time the machine cycles, and it needs to run for an extended period of time. Repeatability is crucial.

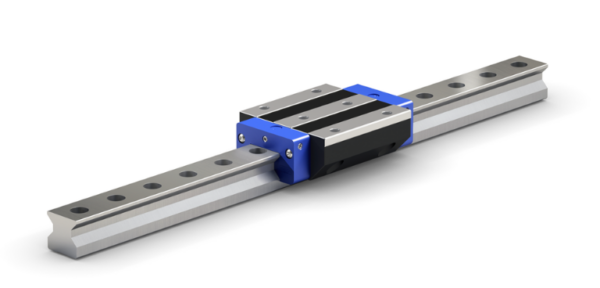

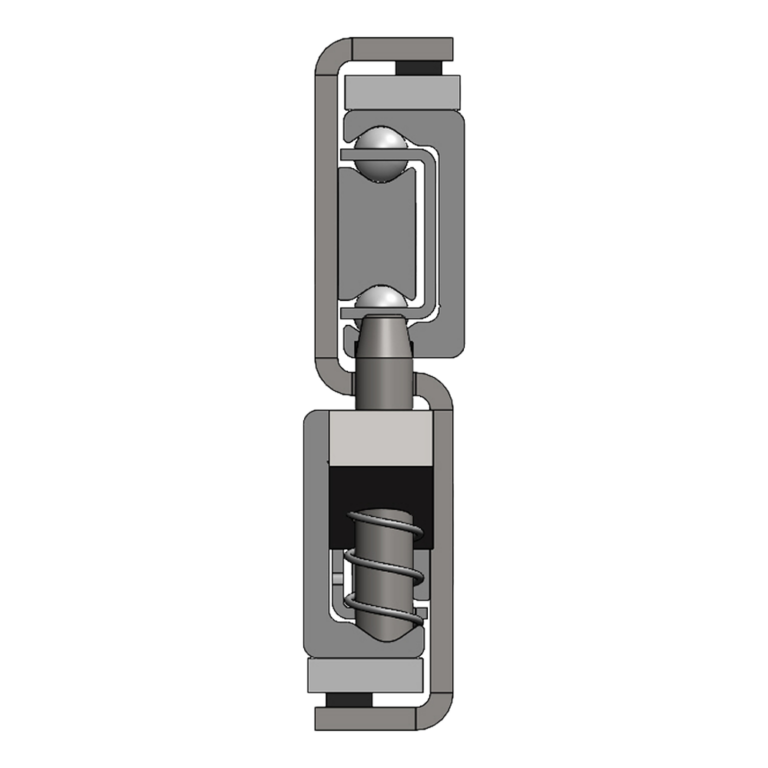

Criterion’s project manager, Noah Hardy, was expecting a complicated telescopic application due to the extreme leverage that the load presented as well as some extenuating factors elsewhere in the drape former. Although improbable, he needed to find an exceptionally strong and rigid drawer slide capable of holding a tight tolerance. With the help of their Rollon representative, Criterion chose Telescopic Rail with caged ball bearings to shuttle the heavy, cantilevered weight. “Prior to Rollon, we didn’t know that was possible,” said Hardy. “Once we saw what the product was capable of doing, there was no other product to consider.”

TELESCOPIC RAIL TAKES THE UNCERTAINTY OUT OF HANDLING HEAVY LOADS.

The Rollon Telescopic Rail proved capable of moving the carbon fibers, table top and vacuum, with the rigidity and tight tolerance that Criterion required. This series of linear rails with caged ball bearings offers several features and benefits that made it particularly suitable to integrate into the layup table section of the carbon fiber drape former, especially:

- High load capacity. Cold rolled steel construction and inductively hardened and ground raceways let them manage heavy loads and give them optimal running properties. In fact, one Telescopic Rail model can support more than 8,300 pounds (~3,800 kilograms) per pair of guides.

- Extremely low deflection. Rollon Telescopic Rails have sturdy profiles to minimize deflections.

- Long telescopic stroke lengths. One particular Telescopic Rail can even extend up to 150 percent of its length, using four elements. Full- and partialextension models are also available, with special stroke lengths upon request.

- Sliding travel with no play, even under maximum load when used 24/7.

- Long life. Inductively hardened raceways ensure a long operating lifetime. After extensive testing, Criterion reports the slide “performed amazingly,” without any issues. The aerospace manufacturer anticipates the helicopter part will go into full production with Rollon Telescopic Rail reliably transporting the heavy, cantilevered load from the layup table to the tools.

After extensive testing, Criterion reports the slide “performed amazingly,” without any issues. The aerospace manufacturer anticipates the helicopter part will go into full production with Rollon Telescopic Rail reliably transporting the heavy, cantilevered load from the layup table to the tools.

This carbon fiber drape former uses Rollon Telescopic Rails to shuttle 2,500 pounds of fiber plies, a vacuum apparatus and steel nearly four feet during helicopter parts manufacturing.

TAKE THE LOAD OFF YOUR MACHINE — AND MIND.

Although the carbon fiber drape former project began with uncertainty, Rollon Telescopic Rail brought nothing but assurance to the designers. “It saved us an unknown amount of design time because we didn’t have to get creative or elaborate. We were able to select the product and move on to designing the rest of the machine,” says Hardy. “It’s hard to measure that.”

Criterion Manufacturing Solutions’ carbon fiber drape former for helicopter parts shows that when a machine must shuttle heavy, cantilevered loads with repeatability and minimal deflection, typical telescoping guides will not meet the challenge. Rollon’s Telescopic Rail family of linear guides with caged ball bearings boasts the sturdy construction and hardened raceways necessary to transport heavy, daunting loads so your machine designs can take flight.