The ONE series is the first belt-driven linear unit capable of achieving ISO Class 3, with all units incorporating high quality reinforced polyurethane timing belts with an AT pitch. Specialized connection ports are featured on both the drive end and idle end of each unit, allowing easy connection of vacuum systems. Any particles generated on the inside of the units are removed by the vacuum system in a controlled and efficient manner. Low-abrasion and corrosion-resistant materials are used throughout the units, along with an advanced lubricant formulated specifically for use in clean room and vacuum environments.

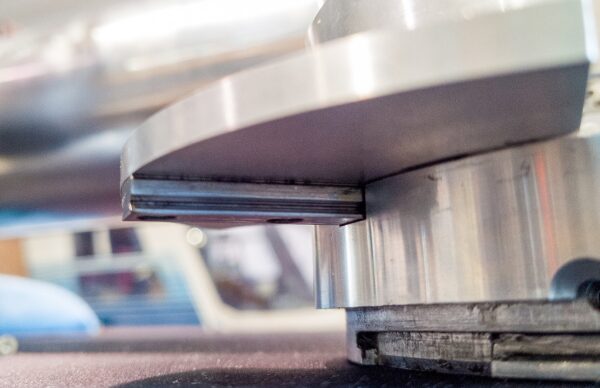

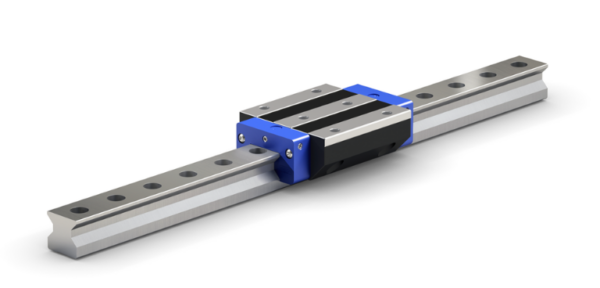

A high strength aluminum profile houses superior quality mechanical components inside. All bearings, linear guides, shafts, pulleys, and other metallic parts are made of stainless steel. In instances where stainless steel cannot be used, surfaces are enhanced with a specialized treatment and tested under severe conditions. The linear guides used in each unit feature a unique spacing cage among the ball rolling elements for low maintenance and low particle generation.

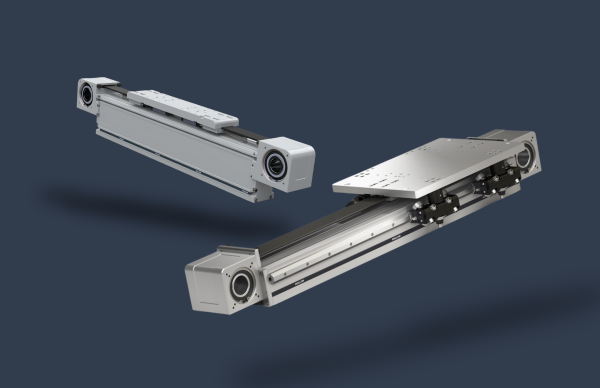

ONE series highlights:

- Speeds to 5 m/s (depending on unit size).

- Maximum dynamic thrust load capacities from 480 to 2,400 N.

- Stroke lengths from 100 to 6,000 mm (depending on unit size).

- Maximum acceleration for all sizes to 50 m/s2.

- Available in three sizes, body dimensions measure 50 x 50 mm, 80 x 80 mm and 110 x 110 mm.

- Multi-axis systems may be constructed in a variety of configurations.