These intralogistical systems present a host of challenging motion requirements that must be addressed. Here are just a few of the important considerations designers and integrators should keep in mind, along with what to look for in a linear motion device:

- The size and weight of the load. Linear guides come in a variety of sizes, and certain guides and actuators are built to handle heavy loads.

- How will horizontal and vertical space be used? Guides can offer partial or full extensions. Certain linear guides can even travel up to 200 percent beyond their length. And, the right actuator can flexibly accommodate a variety of layouts.

- The robotic system’s work range. Actuators create multi-axis systems for Packaging and Packaging and Logistics, palletizing or picking lines, and a specific solution even provides more moveability for robots.

- Precision and accuracy requirements. The right construction can ensure your automated system operates smoothly and accurately.

- The operating environment and expected service life. Be sure your mechanical motion devices can withstand contamination and offer a long lifetime.

There’s a Linear Guide or Actuator Available For Your Specific Requirements

Rollon offers many motion guides and actuators that can address these considerations and meet the demands of different automated warehouse use cases:

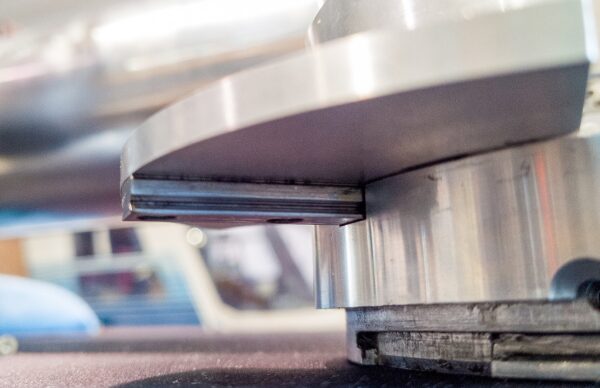

- Telescopic Rail. These linear bearings offer high load capacities, and induction hardened raceways that minimize deflection and provide sliding travel with no play to ensure rigid extractions, even under maximum load and when the rails are fully extended. Their long extraction lengths are particularly effective when multiple storage bins are positioned back-to-back, and bidirectional extraction is also possible. And properly sized cross-sectional dimensions can help fit more goods in a given space.

- Hegra Rail. Pullouts deliver smooth and precise operation even under maximum loads. Rollon offers a large variety of partial, full and overload pull-outs, heavy-duty pull-outs and S-profiles.

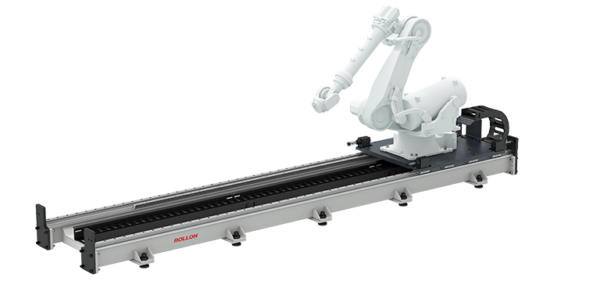

- Seventh Axis. These modular, individually designed movement systems ensure greater mobility and flexibility to extend the work range of industrial robots. A robot moving on a linear axis that is close to the ground can, for example, perform palletizing tasks at multiple points.

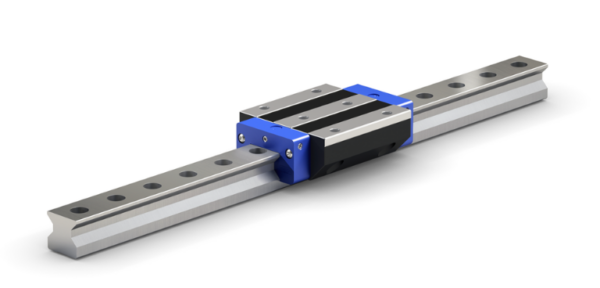

- Compact Rail. Rollon’s Compact Rail system is inherently tolerant of misalignment, thanks to a rail geometry that can absorb alignment errors on one or two axes.

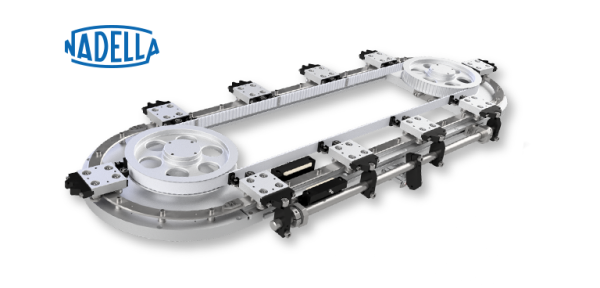

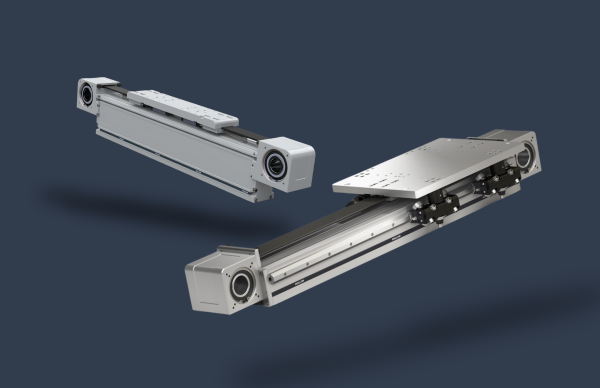

- Smart System. These belt-driven actuators provide high load capacity, high speed and acceleration along with repeatable accuracy, such as required with stacker cranes that must run on X and Z axes. Suitable for stressful work cycles, the actuator’s belt does not need lubrication.

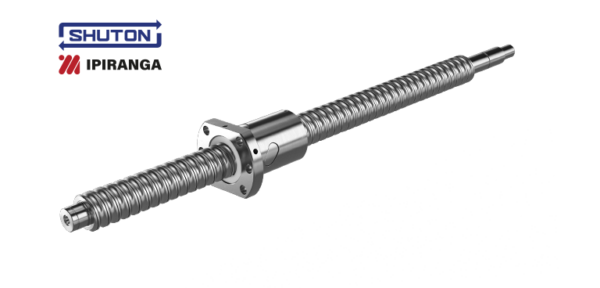

- Actuator Line. This actuator family can create multi-axis systems for palletizers or picker lines. Belt and ball screw driven actuators offer large spans and extremely long Y-axes, high dynamics and long service life with minimal maintenance.

Ensure Efficiency and Reliability For a Successful Implementation

As you take advantage of automated systems to enhance material storage and retrieval operations, the right actuator or linear guide can meet your exact motion requirements and operate reliably to ensure a successful implementation. Rollon offers a wide range of mechanical motion products that enable dynamic processes, offer long travel lengths, handle heavy loads and stand up to harsh environments. These motion products can help designers and integrators get the best results for their material handling systems.