In the Food & Beverage sector, machine productivity and component protection from product contamination are essential.

Linear motion components cannot be outdone in this respect. They need to ensure the non-contamination of products and of the operating environment, while being able to withstand cleaning interventions without suffering a deterioration in functionality; guarantee a long life and low maintenance, even with high dynamics; effectively respond to any application and environmental need.

Rollon boasts many years of experience within the sector and has developed several solutions that can efficiently operate in environments with a high risk of contamination, ensuring maximum protection and performance at the same time.

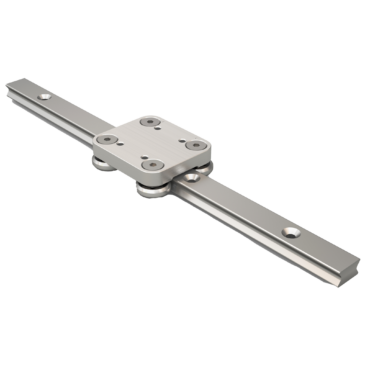

In addition to the stainless-steel X-Rail and Curviline linear rails, Rollon has recently launched the MiniRoller Rail, a linear guide with an adaptive design that saves space and installation time. It features radial roller bearings that glide on honed and induction hardened raceways between 58 and 62 HRC, ensuring longer lifetime and a smooth and silent motion. The rollers can be preloaded to customize rolling force and motion characteristics, thus making it a suitable solution for applications that move moderate loads within tight spaces. MiniRoller Rail also manages parallelism deviation up to 0.03 mm.

The rails of MiniRoller Rail offer higher corrosion resistance and mitigate food contamination with a nickel-plating treatment. The slider body, and rollers with radial ball bearings, are stainless-steel. The bearings are enclosed with 2RS splash-proof rubber seals, to withstand washdown and food contamination, with FDA approved grease as optional.

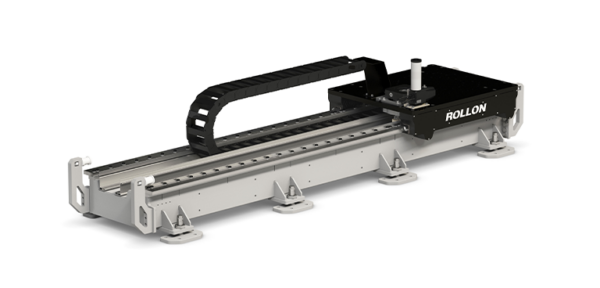

When it comes to driven actuators and systems, Rollon has designed the Plus System series. This family of actuators include the ELM linear axis. These linear belt actuators with specially designed extruded aluminium profiles and integrated linear recirculating ball guides are the most suitable choice when it comes to resistance to liquids and contaminants. In fact, a lipped polyurethane protective strip seals the extruded aluminium profile, preventing contaminants and liquids from affecting the function of the bearing elements contained within. The ELM series can also be positively or negatively pressurized with approximately 0.7/0.8 atmospheres being more than enough to create a solution which, although not hermetic, allows for an excellent seal. In addition, a corrosion-resistant version with stainless steel components is available. The other two members of the Plus System family are the ROBOT, with double recirculating ball guide for the heaviest loads, and the SC, specifically designed for vertical movement.

Rollon’s support doesn’t stop at product-level. When analyzing the application requirements and designing and installing the solution, customers can capitalize on Rollon’s experience in designing and implementing complete linear motion solutions and systems that can be customized to meet individual application needs.