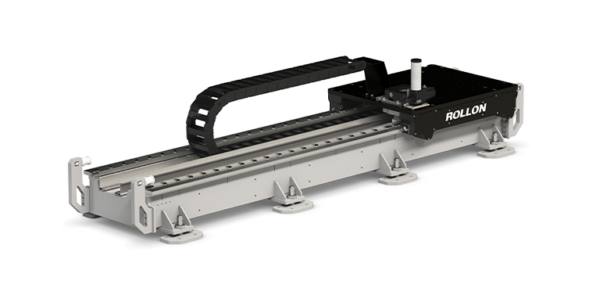

In this real application example, Rollon helped an emerging AGV manufacturer to create a complete warehouse automation solution for a major retailer. Rollon’s experience, consultative approach and profound technical expertise in linear motion made expanding the company’s solution portfolio achievable. It’s about having the right partner to do it with.

Over the last few years, the logistics and intralogistics sectors have seen their activities increase exponentially in relation to consumer demand. The consequence of an ever-increasing online purchasing trend is having an enormous impact on the number of orders that need to be physically managed in a warehouse.

Intralogistics automation applications have “benefited” the most as a result. Designers must work hard to reduce turnaround times by creatively developing effective solutions from pick and place sorting operations to storage, retrieval, presentation for picking, packaging and palletising stages to get to the final shipping phase.

AUTOMATIC WAREHOUSES WITH HIGH PERFORMANCE AND LOW MAINTENANCE

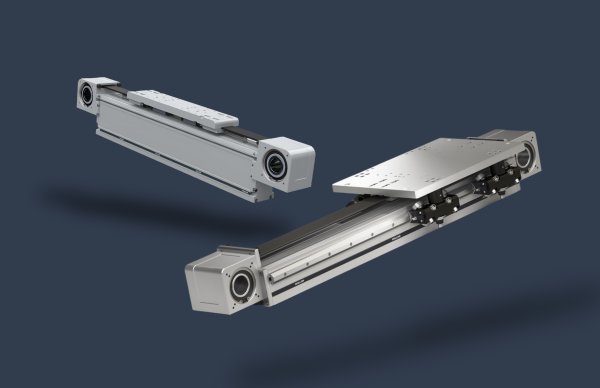

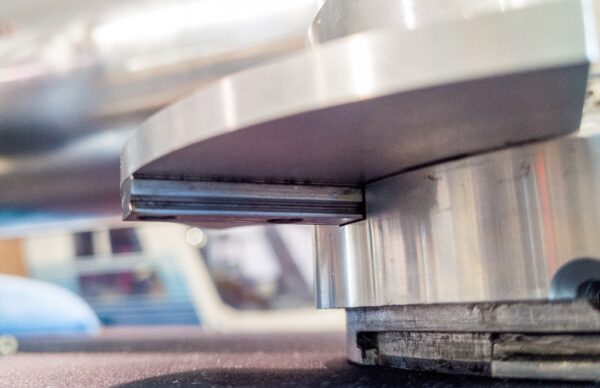

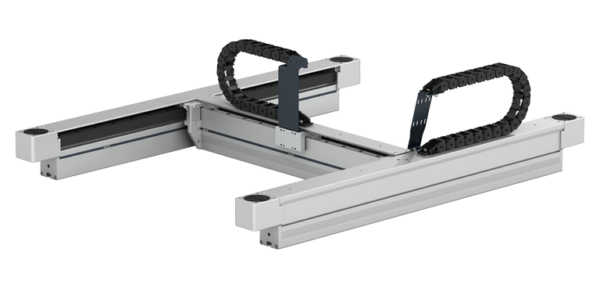

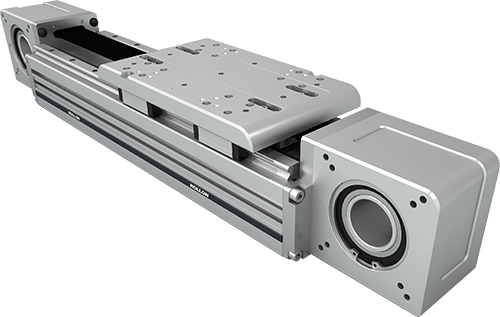

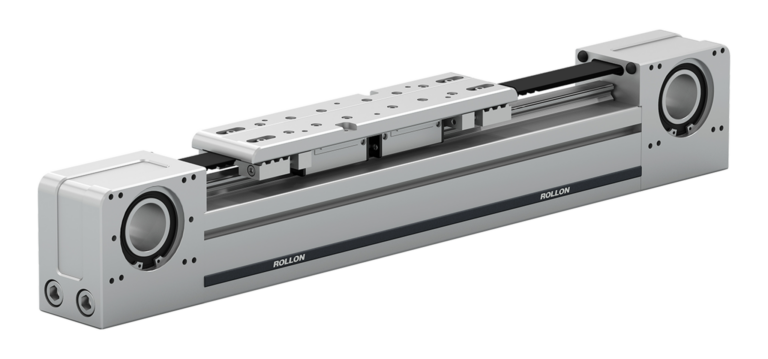

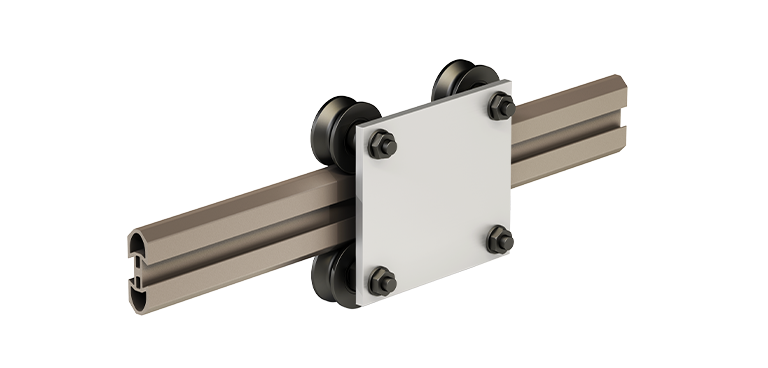

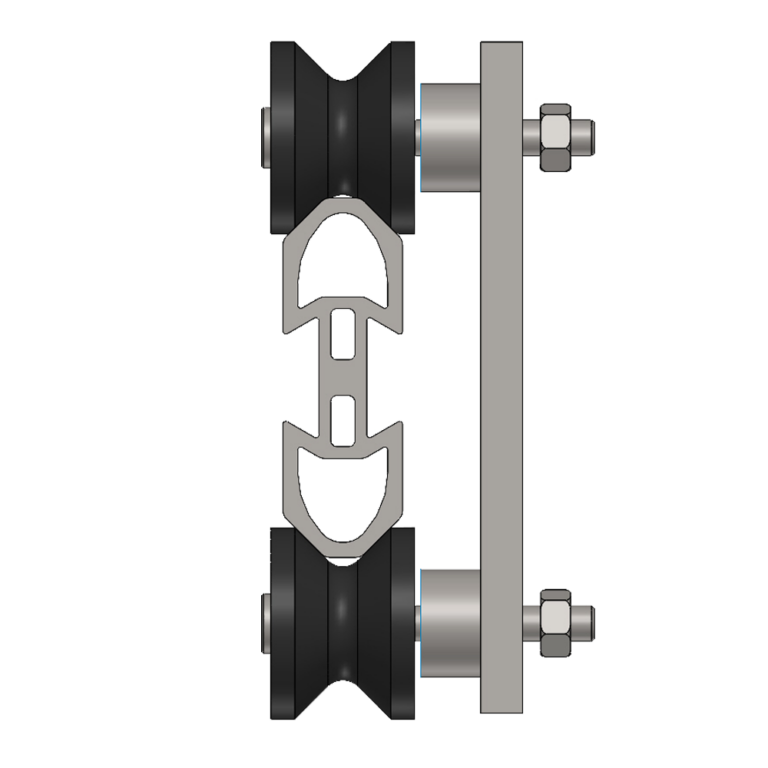

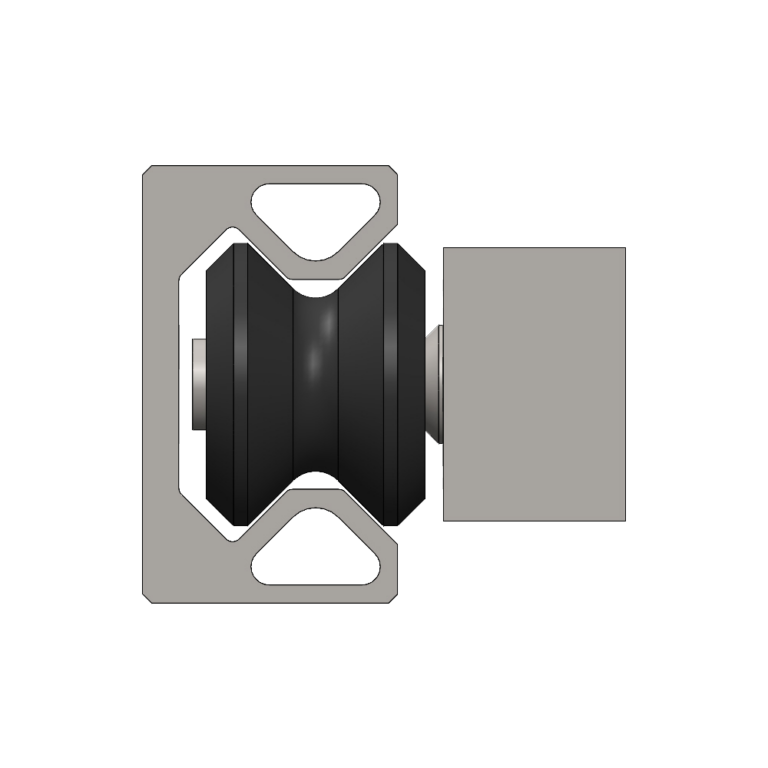

When Rollon was approached to help develop a tote management system that could not be fulfilled by AGVs alone, it was an ideal opportunity to assist a company that had never integrated linear axis and gantry portals before.

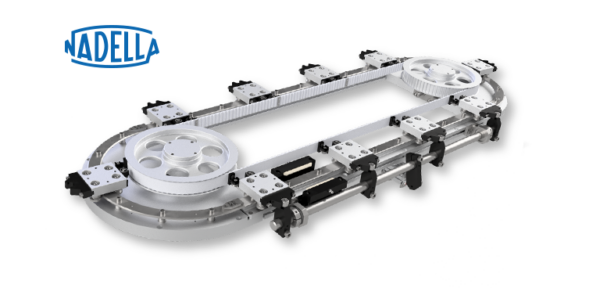

Empty totes enter the warehouse after returning from a delivery round and are carried around by AGVs to various points. At some stage, a vertical lift to take totes from one level of the warehouse floor to the next is necessary. Additionally, a system to store totes in an isle racking arrangement and a system to buffer totes in racks while the order of totes with picked items is determined was also needed, such that they are delivered to the exit of the warehouse in an orderly fashion for the next round of deliveries to online shoppers.

All this had to be versatile enough to be installed throughout already existing but manually operated warehouses.