Integrated Quality Policy

Introduction

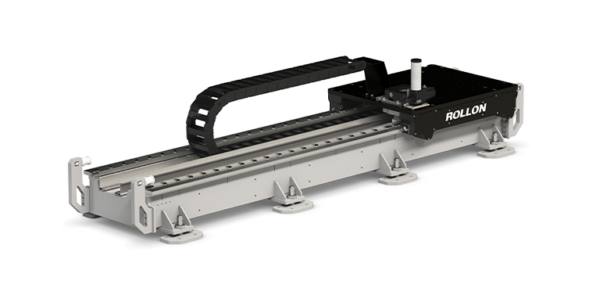

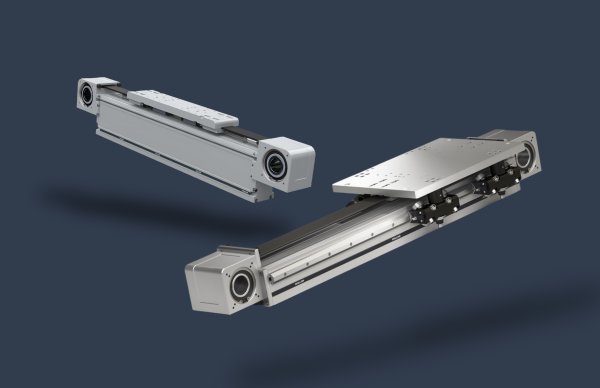

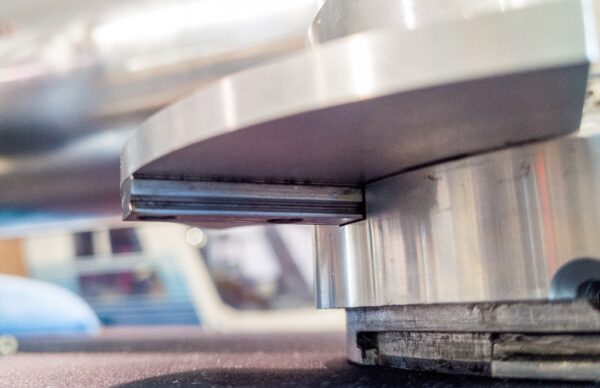

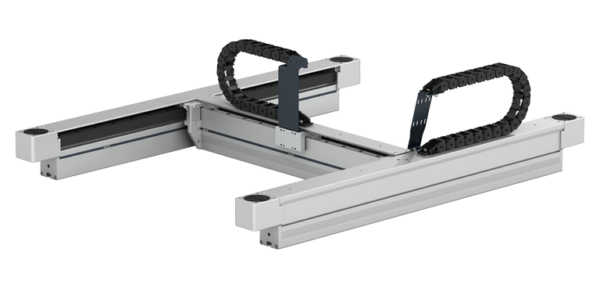

Rollon, a company leader in the design, production and sale of linear guides and systems, considers the health and safety of its staff, the requirements and satisfaction of its customers, environmental protection and the development of communities with which it interacts to be absolute priorities, integrated into all its activities; the entire organization is oriented towards achieving these objectives openly and transparently.

The strategy implemented is based upon, favoring preventive actions, legislative compliance and respect of applicable regulations and aims continuously to improve health and safety quality performances in the workplaces and the environment.

Vision

Rollon‘s Vision is to become the global reference partner for all customers seeking solutions to their linear motion problems on their products in the relevant sectors: aerospace, rail, logistics, medical and industrial machines.

Mission

Rollon‘s MISSION is to satisfy all stakeholders involved in the group’s activities, guaranteeing a high quality, safe and reliable product, and managing risks and opportunities that:

• may have an impact on the proposition of value, particularly on the offer of products and services;

• may have an impact on environmental performances and the health and safety of staff;

• fully satisfy the demands of our customers, creating value for the company, its collaborators and the community.

Principles of reference

Rollon defines as the principles of reference of its Quality Policy:

Attention focused on the customer and on the stakeholders

• Rollon undertakes to understand the needs of customers and plans its activities to satisfy them fully in respect of the relevant market, the country in which they operate and all parties involved

Approach by processes

• Rollon identifies the different activities of its organization as processes to be constantly planned, controlled and improved and it activates the resources for their implementation, also taking steps to assess and manage risks associated with the processes, encouraging widespread and adequate proactive risk management actions.

Involvement of staff and stakeholders

• Rollon strengthens its human resources through constant training and development of professional and managerial skills, by motivating its employees and maintaining an adequate balance between the quality of life of its employees and its business requirements.I

Continuous improvement

• Rollon sets itself the permanent objective of improving its performances by way of the preliminary assessment of opportunities and risks connected to the company processes, internal and external audit activities and the Management review.

Health and safety

• Rollon undertakes to keep the workplace safe and secure. Those values are essential and are treated as an integral and strategic part of its activity.

Environment

• Rollon undertakes to run its activities in respect of the environment and sustainable development, being careful to: reduce pollution, emissions, waste, use energy and water efficiently, minimize noise and recycle materials.

Objectives

The strategic objectives and specific Improvement Plans defined annually in the Management Review aim:

• To guarantee Business Continuity and the safety of its products

• To contribute to the growth of the entire Rollon Group, focusing on research and development of new products oriented towards market demands

• To guarantee respect of qualitative, quantitative, temporal and economic requirements of its offer of products and services and environmental and health and safety aspects in conformity with mandatory regulations, considering as a priority the needs of all stakeholders and implementing actions to prevent non-conformities;

• To implement methods of measuring the performances and processes of the Quality, Environment and Health and Safety Management System by defining monitoring indicators;

• To guarantee the security of the information systems and to preserve information, guaranteeing its availability, confidentiality and integrity;

• To act in full respect of the national and international rules and laws in force applicable to its business sector;

• To implement and continuously improve the company Management System, in conformity with the standards:

UNI EN ISO 9001:2015 – certified

UNI EN ISO 9100:2018 (solely for the Vimercate production unit) – not yet certified, certification process in progress

UNI EN ISO 14001:2015 – not yet certified, certification process in progress

UNI ISO 45001:2018 – not yet certified, certification process in progress

• To focus on operating efficiency of the design and creation processes of its products, through methodologies of proven effectiveness.

Strategies & Keywords

• Guarantee of Quality, Safety of the product and On Time Delivery

The company measures its performances in terms of product / service conformity and punctuality of deliveries and it undertakes continuous improvement actions aimed at the “0 deviation” mission.

• Environmental sustainability

The company operates with a view to preventing pollution and achieving regulatory conformity and the continuous improvement of its environmental performances

• Health and Safety

A safe and secure workplace is a fundamental right for each of us and it also represents a company philosophy

• Internationalization

Acting locally, dealing with the market with a global perspective

• Innovation

Commitment to research and development of new systems and new technological solutions

• Uniqueness

Originality and reliability of products offered for advanced finishes in the relevant industrial sectors

• Evolution

Operating in continuous interaction and adaptation to dynamic scenarios and contexts of reference

Certification Scope: UNI EN ISO 9001 (certified)

“Design, manufacture and sale of linear bearings and linear system”

Certification Scope: UNI EN 9100 (not yet certified, certification process in progress)

“Design and manufacturing of linear guides for ASD industry”

Certification Scope: UNI EN ISO 14001 (not yet certified, certification process in progress)

“Design, manufacture and sale of linear bearings and linear system”

Certification Scope: UNI ISO 45001 (not yet certified, certification process in progress)

“Design, manufacture and sale of linear bearings and linear system”

Vimercate (MB) dated 10.30.2020

Ing. Stefano Zecchinato

Headquarter Contacts

Via Trieste 26, 20871

Vimercate MB

Tel + 39 039 62591

www.rollon.com