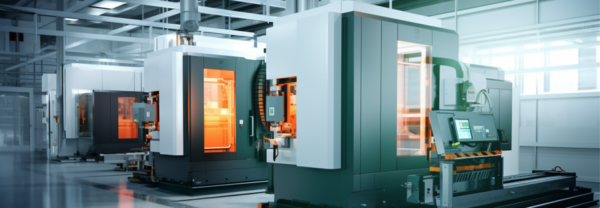

Laser marking is nowadays one of the most important technologies for performing small and precise markings in many different industries.

The ability of laser marking systems to improve efficiency, precision, and long-lasting marking has made this tool an invaluable asset to various fields, including automotive, aerospace, medical devices, electronics, and jewellery.

What is Laser Marking?

Laser marking is much like an evolution of traditional engraving or printing. Laser marking is a process that, much like the more traditional methods, creates marks on a material’s surface; however, it uses a laser beam to do so.

Using a laser beam means there is no physical contact with the material, resulting in minimal wear and tear on the equipment. It also ensures that the process is cleaner and does not create chips or dust. The marks created by the laser marking process are more permanent and resistant to environmental factors such as heat, chemicals, and abrasion.

Laser Marking Machines: How Do They Work?

The laser marking process is carried out by laser marking machines. These machines are made up of a laser source, which is the core of the machine that generates the laser beam used for marking; a control system, which manages the operation of the laser marking machine, including the movement and intensity of the laser beam; the beam delivery system, which directs the laser beam from the source to the material’s surface, often including mirrors and lenses to guide and shape the beam; and the focusing optics, which concentrate the laser beam into a small spot to increase its power density and achieve high precision details.

Advancements in Laser Marking Technology

Modern laser marking systems have seen rapid advancements in technology compared to previous years. For example, laser marking can now be used on a much wider range of materials, including plastics, ceramics, and glass. Additionally, more types of marks are available, such as annealing and foaming.

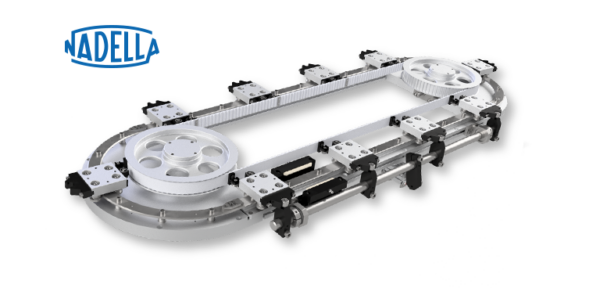

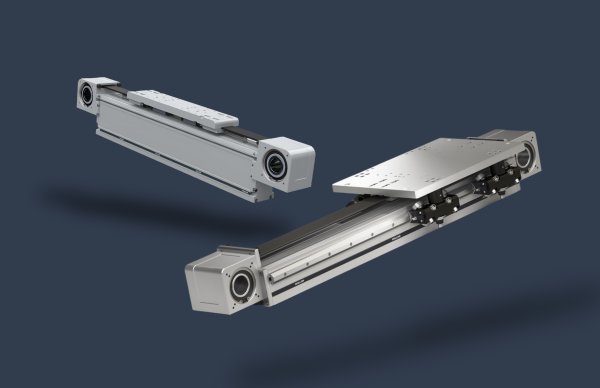

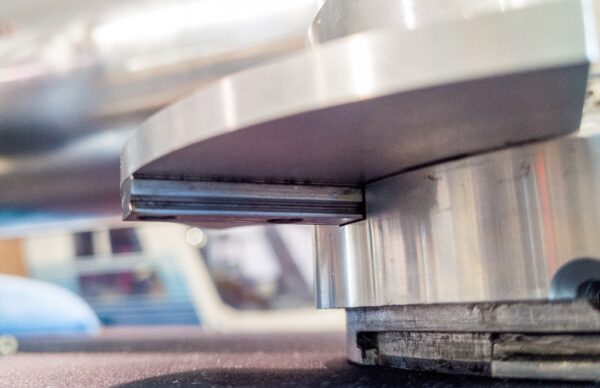

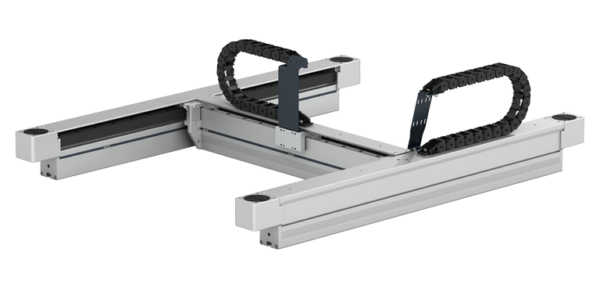

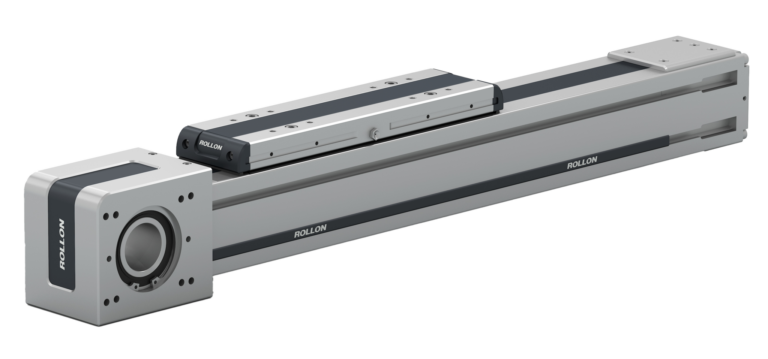

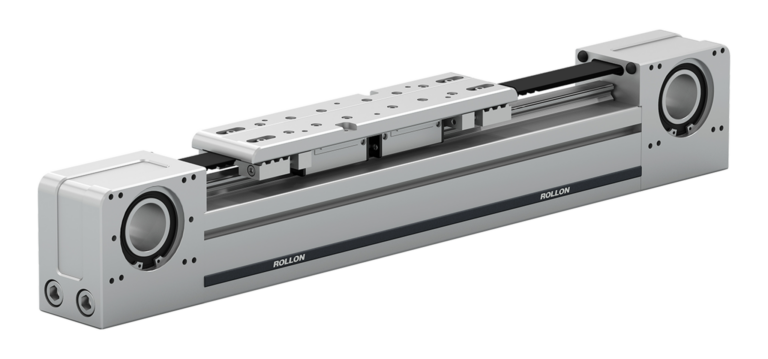

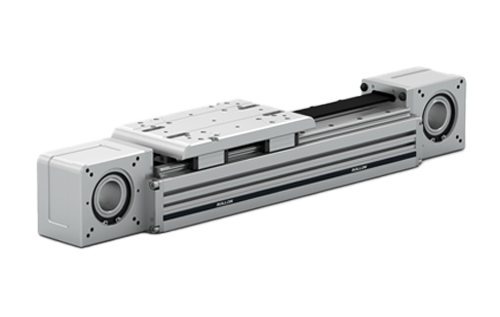

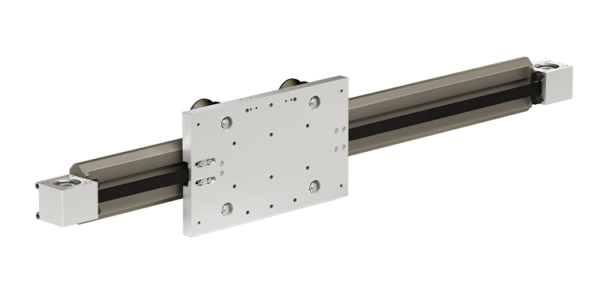

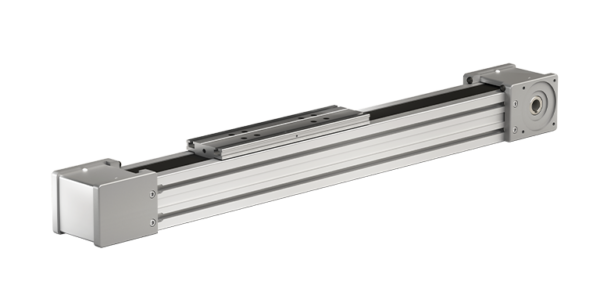

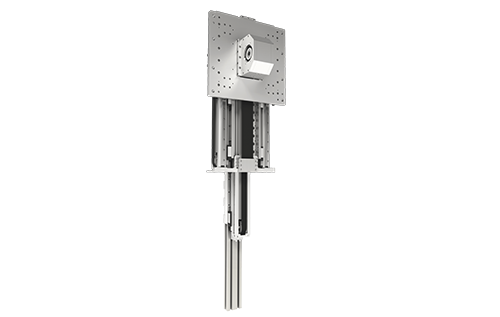

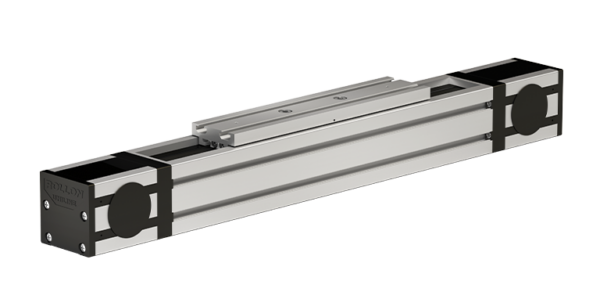

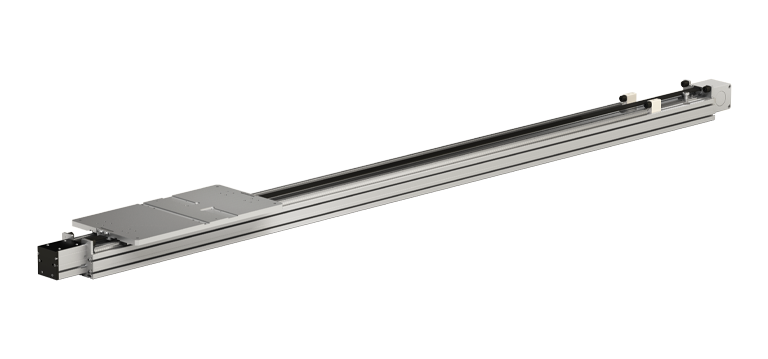

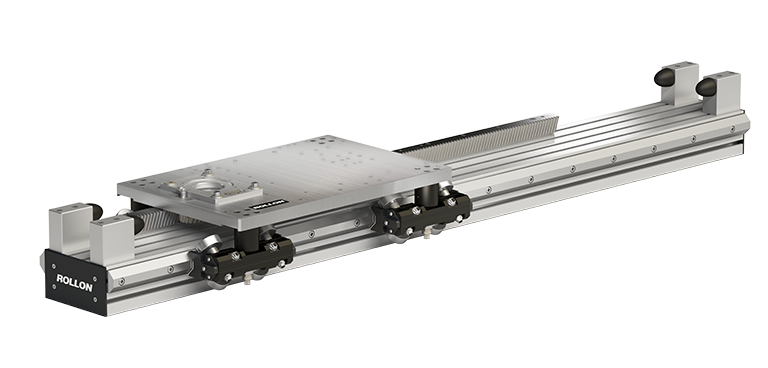

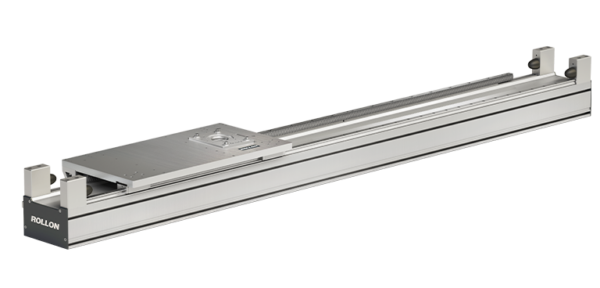

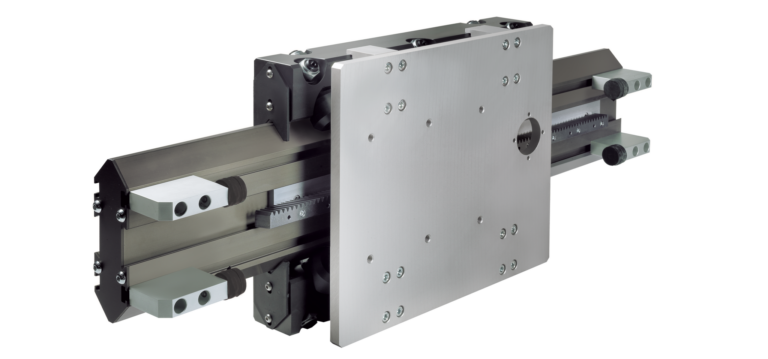

One notable advancement in laser marking technology is the integration of multi-axis systems, which allow for the marking of complex shapes and surfaces. These systems use linear actuators, which are essential components for providing precise and smooth movements.

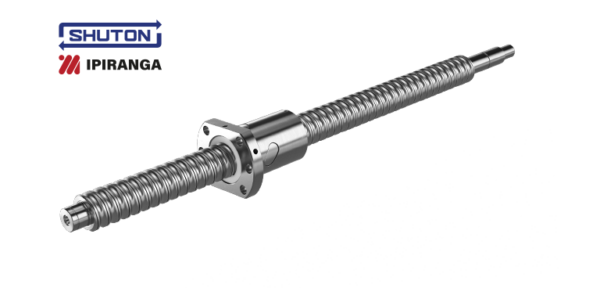

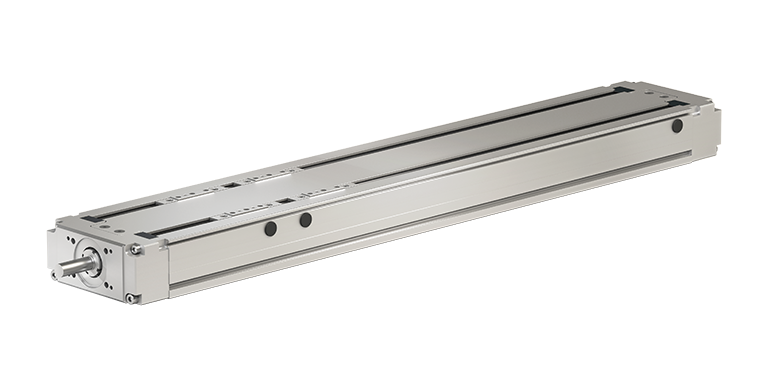

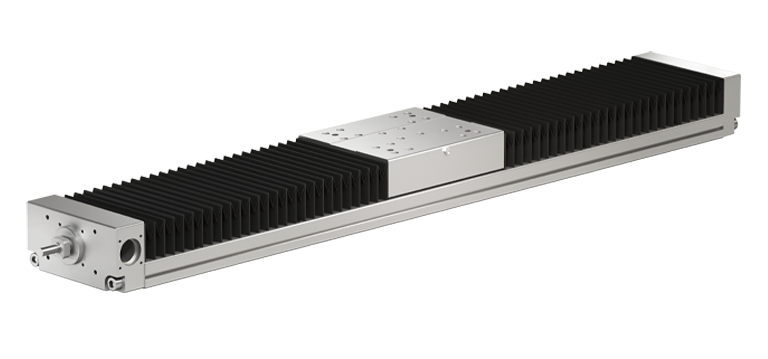

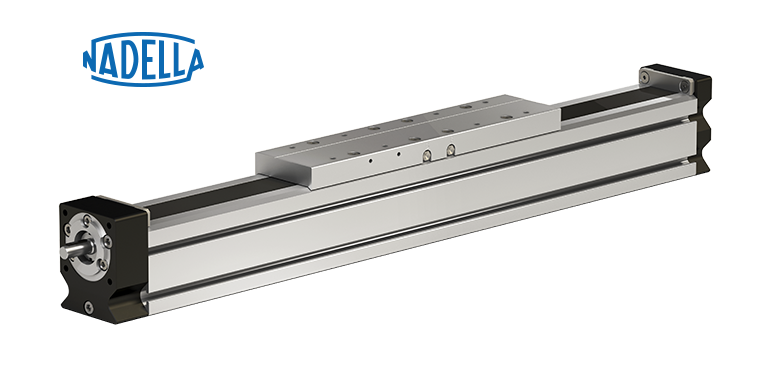

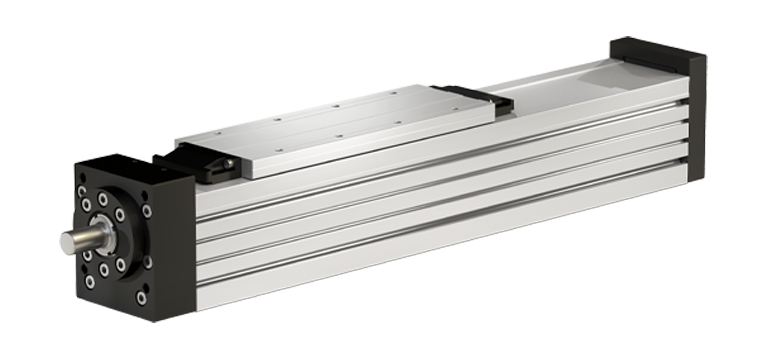

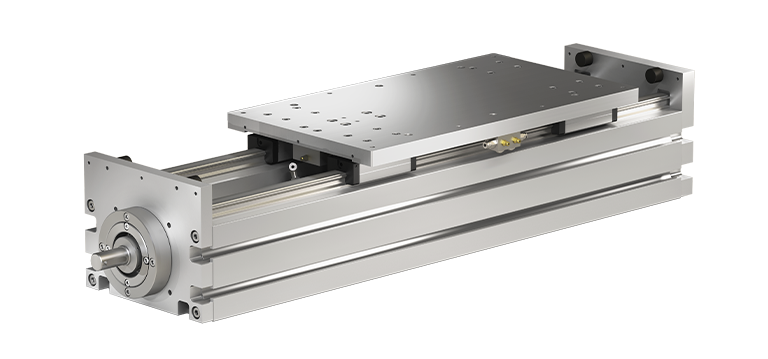

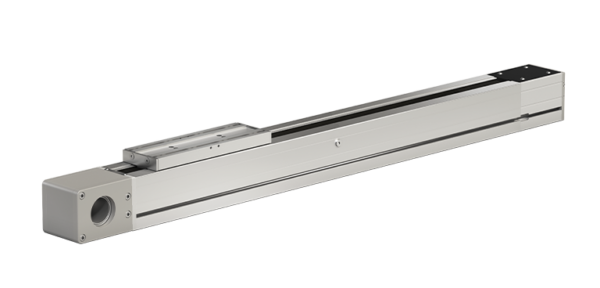

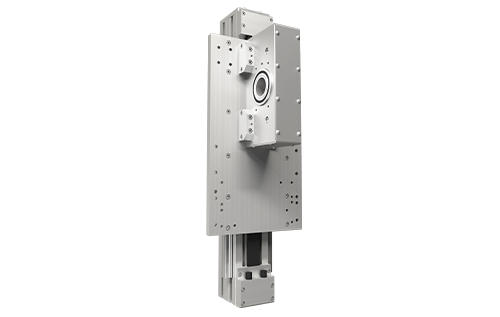

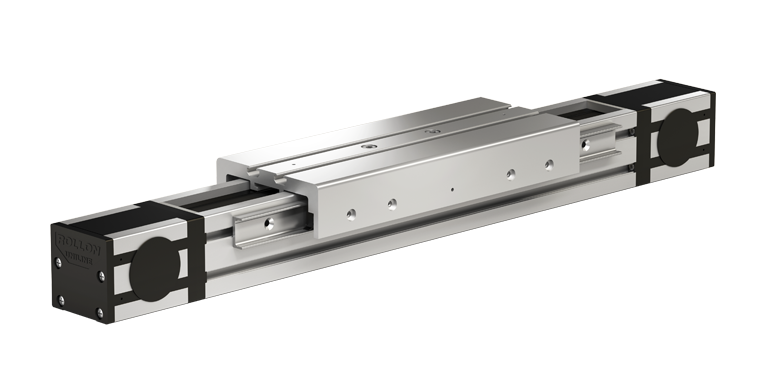

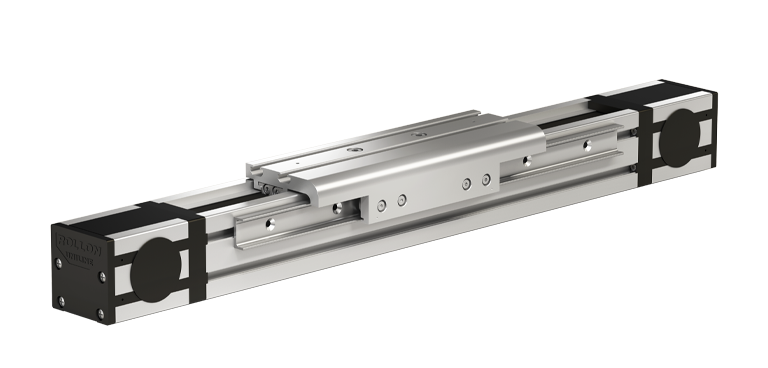

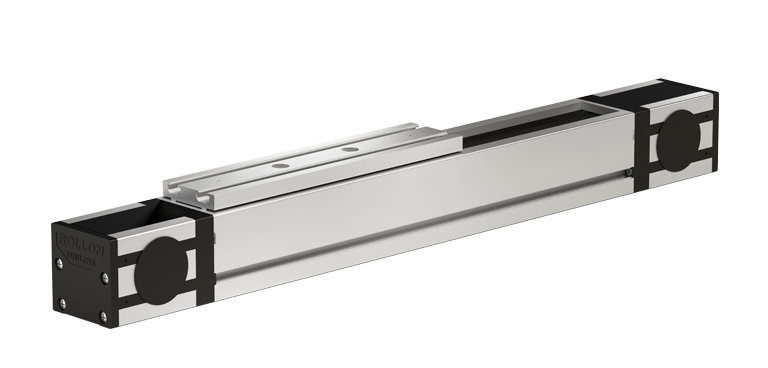

Ball screw driven linear actuators provide high load capacity, accuracy, and repeatability, which are crucial in applications where exact positioning and stable movements are necessary, such as in laser marking systems.

The Role of Actuators in Laser Marking

Much like ball screw driven linear actuators, many different types of actuators play a vital role in the functionality of laser marking systems.

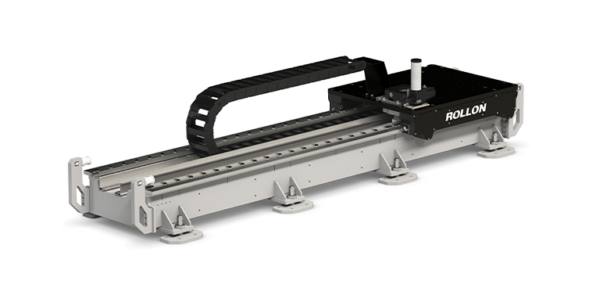

The use of high-quality actuators, like those displayed in the Rollon catalogue, ensures that laser marking machines can maintain consistent performance over long periods of time. This is especially important in industries where there is a high volume of markings. For instance, in the electronics industry, components often require many small and precise markings that can only be achieved with the support of linear actuators.

FAQs

What industries benefit the most from laser marking technology?

Industries that benefit the most from laser marking technology include automotive, aerospace, medical devices, electronics, and jewellery. Traceability is key in today’s marketplace especially in those safety critical industries such as aerospace.

How does laser marking compare to traditional marking methods?

Laser marking offers greater precision, durability, and versatility compared to traditional marking methods, as it can produce high-resolution, permanent marks without physical contact with the material.

Can laser marking be used on all types of materials?

Laser marking can be used on a wide variety of materials, including metals, plastics, ceramics, glass, and more.