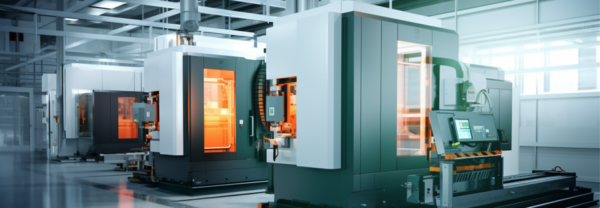

The introduction of robotics and automation has transformed the car manufacturing industry, making it more efficient, precise, and cost-effective.

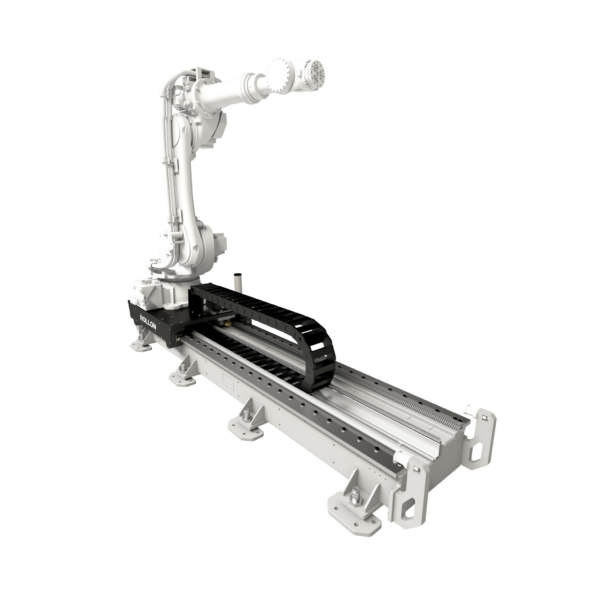

This article explores the car manufacturing process, highlighting the benefits of assembly line automation, and explores the integration of new technologies, including a focus on Robotic tracks or Robot Transfer Units (RTUs)

Car manufacturing process

The automotive industry, being a multi-billion-dollar business, is always at the forefront of manufacturing innovation. Today’s high-quality vehicles all rely on robotic integration during the manufacturing process. This process is a complex series of steps transforming raw materials into a finished vehicle.

Firstly, the car is designed and prototyped; engineers and designers work together to create the blueprint from which the vehicle will be made. Once the design is finalised, it is time for the production phase, which can be divided into five stages: Stamping, Welding, Painting, Assembly, and Testing.

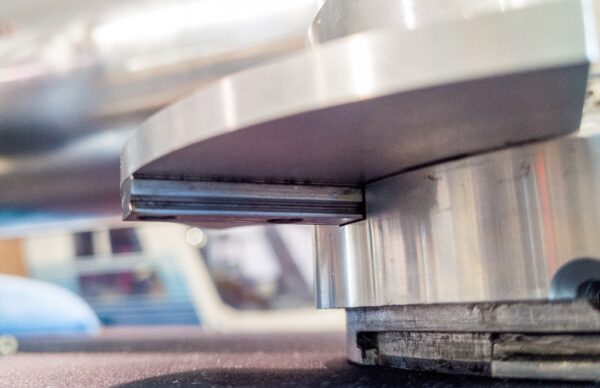

The initial stage, Stamping, involves large sheets of metal that are cut and shaped into the future body parts of the car. Once the body parts are shaped, they are assembled and welded together to create the frame. After the frame of the car is formed, it goes through a painting process, which involves multiple steps to not only give colour to the vehicle but also prevent corrosion.

Finally, the car is moved onto the assembly line, where all the various components are installed. This is the trickiest stage, which requires precision and coordination to ensure that each part fits perfectly and is correctly connected. The last step is to test and inspect the car to make sure it adheres to safety standards.

Benefits of assembly line automation

When the first cars were being built, there was not really a rigorous assembly line. However, nowadays, the incorporation of assembly line automation in car manufacturing has brought numerous benefits. Thanks to the usage of robots and computerised systems, the repetitive tasks required in the car manufacturing process are all performed by robots, ensuring precision and accuracy.

Automated systems significantly reduce the time required for each manufacturing step and ensure that each vehicle is built with the same level of attention to detail and high standards. Additionally, even though the initial costs of automated technologies might be substantial, labour and material costs are reduced, and material wastage and rework is minimised.

Integrating New Technologies

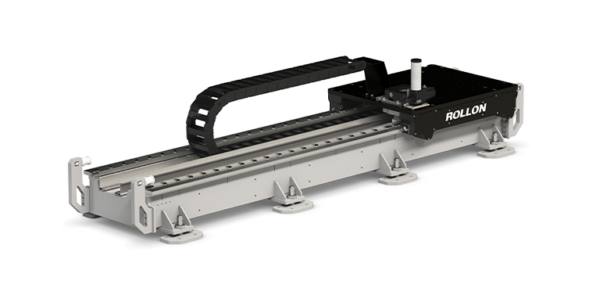

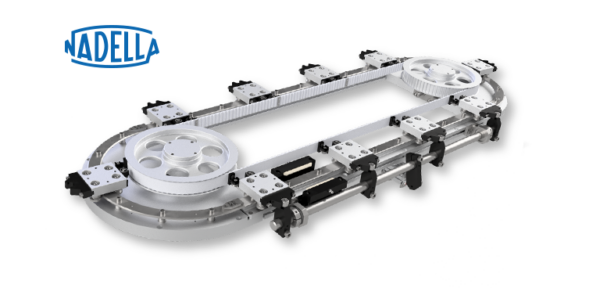

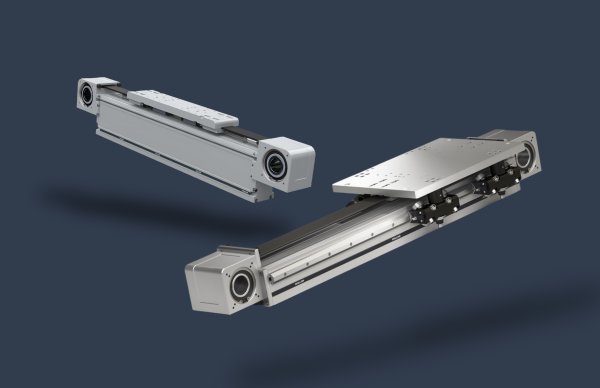

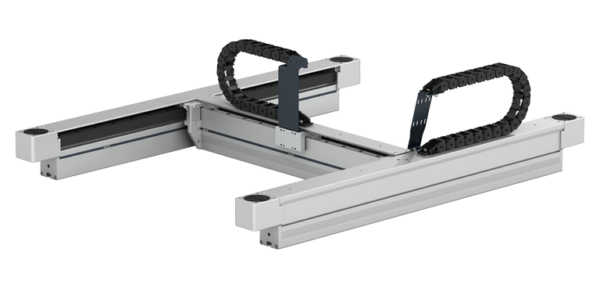

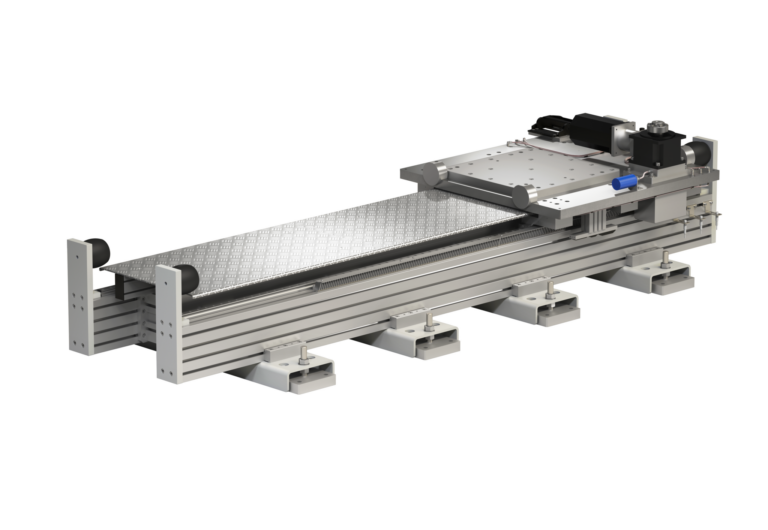

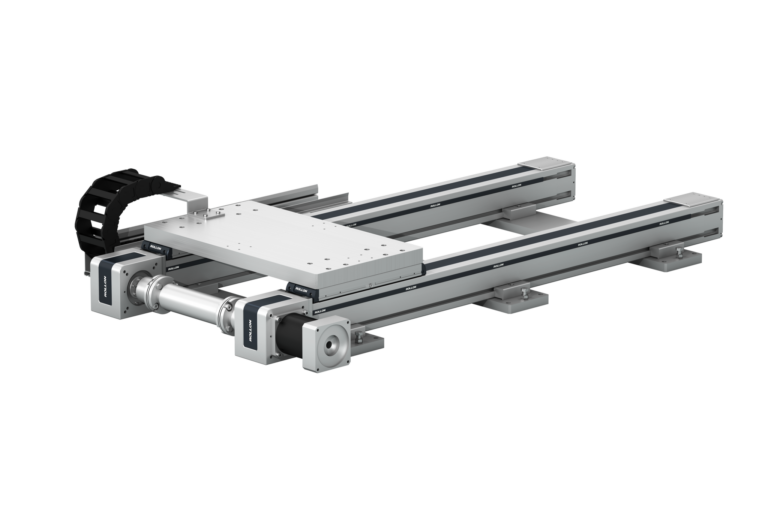

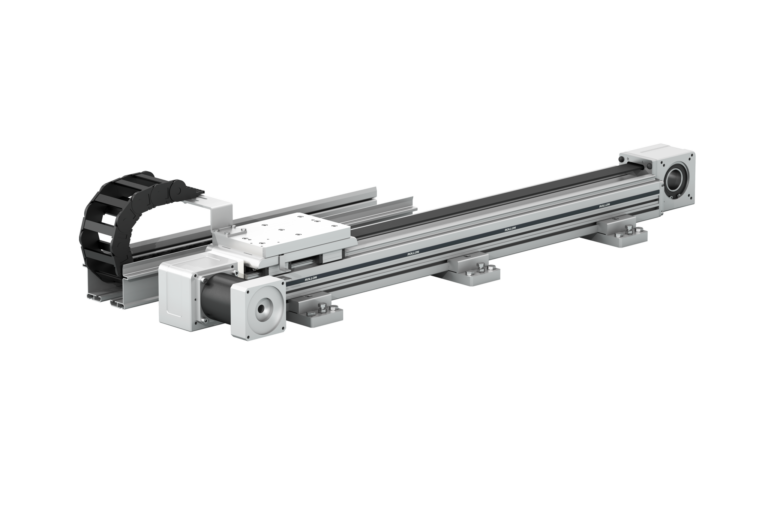

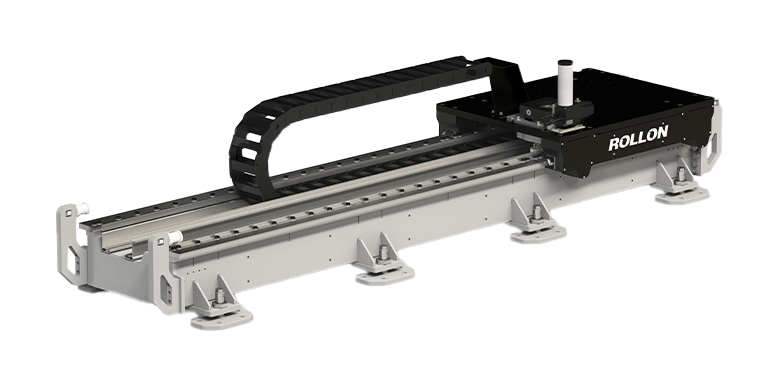

Automated car manufacturing is an ever-evolving field with innovations and new technologies emerging regularly. For example, Robot Transfer Units, or RTUs, are now used in car manufacturing processes to transport components or assemblies between different stations on the production lines.

Robot Transfer Units are highly flexible and can be programmed to handle many different tasks, such as moving car bodies, laser scanning and transporting smaller parts. The use of Robot Transfer Units in car manufacturing not only speeds up the process but also allows manufacturers to quickly adapt to any changes in the assembly line, thanks to their flexibility.

Future Trends in assembly line automation

As the automotive industry continues to evolve, so does the technology used in manufacturing. Some future trends we can expect include the use of Industry 4.0 including AI, machine learning and a shift toward sustainable manufacturing.

As AI and machine learning models are increasingly integrated into various industries, these technologies will enable manufacturing systems to perform predictive maintenance, quality control, and optimise the production process even further.

With growing environmental concerns, sustainable manufacturing practices appear to be the future of car manufacturing. This includes the use of eco-friendly materials, reducing energy consumption, and minimising material waste.

FAQs

How do Robot Transfer Unit impact productivity in car manufacturing?

Robot Transfer Units enhance productivity in car manufacturing by speeding up the transportation of components between stations, minimising the need for rework due to consistent tolerances and the use of full 3D car body scanning to ensure quality standards are always met

What safety measures are essential when integrating robotics in car manufacturing?

Essential safety measures when integrating robotics in car manufacturing include proper training for workers, installing safety barriers and sensors, regular maintenance, and compliance with safety standards and regulations.

How does robotic integration affect the workforce in car manufacturing plants?

Robotic integration in car manufacturing plants can reduce the need for manual labour involving repetitive and dangerous tasks. The workforce can be deployed into highly skilled roles for example the programming and utilisation of such technology.